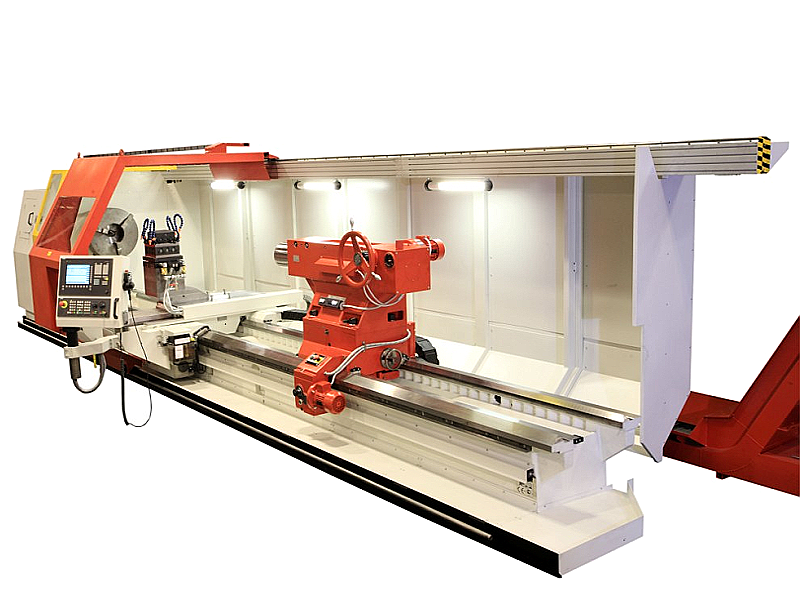

SUA63 Numeric

The universal centre lathe SUA63 NUMERIC

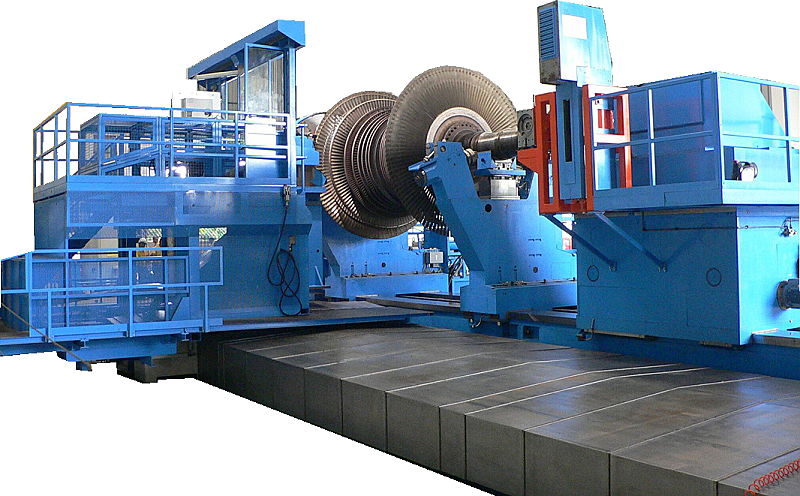

The universal centre lathe SUA63 NUMERIC is a numerically controlled machine designed for roughing and finishing of shaft-parts and flanges, threading, boring, turning of tapers and various cylindrical parts. The output 30 kW allows heavy duty turning of items weighing up to 6000 kg without steady rest and up to 8000 kg with steady rest. Maximum torque of the spindle is 8000 Nm. Our standard version is delivered with distances between centre are 1250, 2000, 2750, 3500, 5000, 6500, 8000 mm 9500 mm and on a customer request up to 11 000 mm.

The machine has the rigid horizontal bed of design with hardened and ground guide-ways. The counter surfaces of saddle are covered with slide plastics Turcite B to prevent the stick-slip effect at small feeds.

The SUA 63 NUMERIC with cycle control can be equipped with control system of your choice as from company Heidenhain, Siemens alternatively Fanuc

The spindle drive is derived from asynchrony motor which is controlled by frequency regulator. The spindle revolutions are infinitely variable in all three ranges shifted hydraulically.

The drive of longitudinal feed – axis Z – is done by servo-drive mounted directly on the balls-crew. On the longer lathes over 3500 mm the drive is through the apron which contains two pre-loaded pinions with backlash elimination, which drive a rack.

The drive of cross feed – axis X – is again by servo-drive directly on the cross ball-screw. The measuring of both axes is provided by rotary sensors placed on servo-drives. On machines with longer distance between centre is the axis Z measured directly by of linear rule. The lubrication of gears in headstock, hydraulic operation of spring spindle brake and speed shifters is provided by lubrication and hydraulic unit placed on the rear side of the bed. The monitor and control board of control system is integrated into box and placed in front of the guard where are also placed two electronic hand wheels. The machine can be equipped with either hand operated tool head or with multi position CNC controlled turret head of various manufactures. Also, the machine can be equipped with chip conveyor as well as other extra accessories according to customer s requirement incl. The electrical equipment and control system are in the switchboard placed near to operator.

The machine is covered by compact rear wall and moving front door.

Does this model not meet your needs? We also have bigger option. More information to be found in our catalogue. The manufacturer reserves the right to change the product parameters and design without prior notice.

KL285

KL435

SE520 SL

SR1, SR2, SR3, SR4, SR5

MANURHIN K’MX 1032

MANURHIN K’MX 916 CLEVER

MANURHIN K´MX816 CLEVER

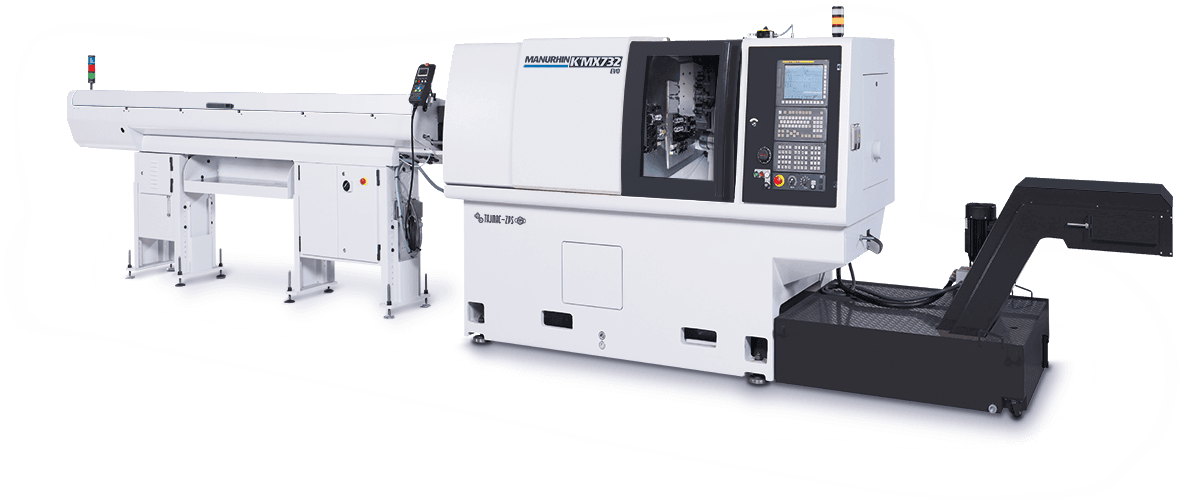

MANURHIN K´MX732EVO

MANURHIN K´MX632DUO

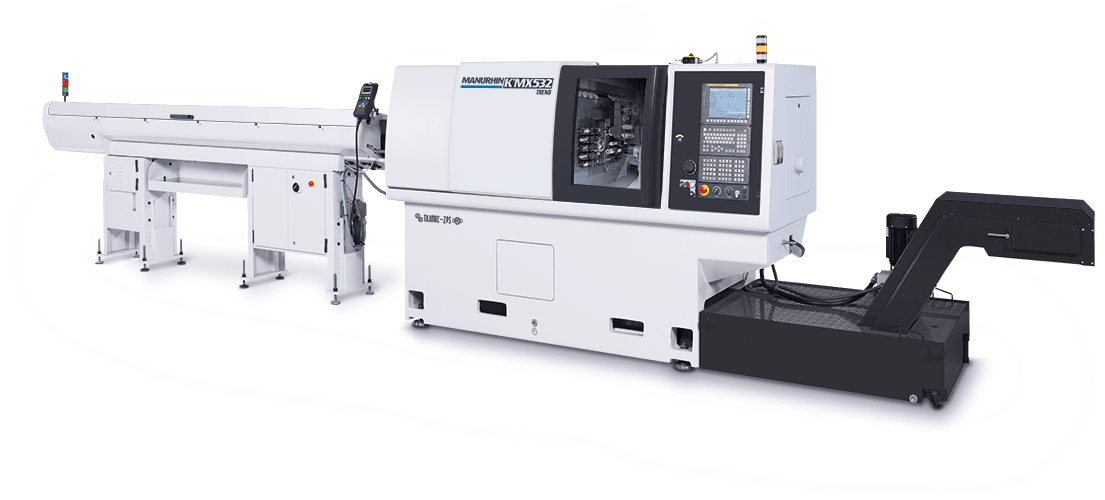

MANURHIN K´MX532 TREND

MANURHIN K´MX432

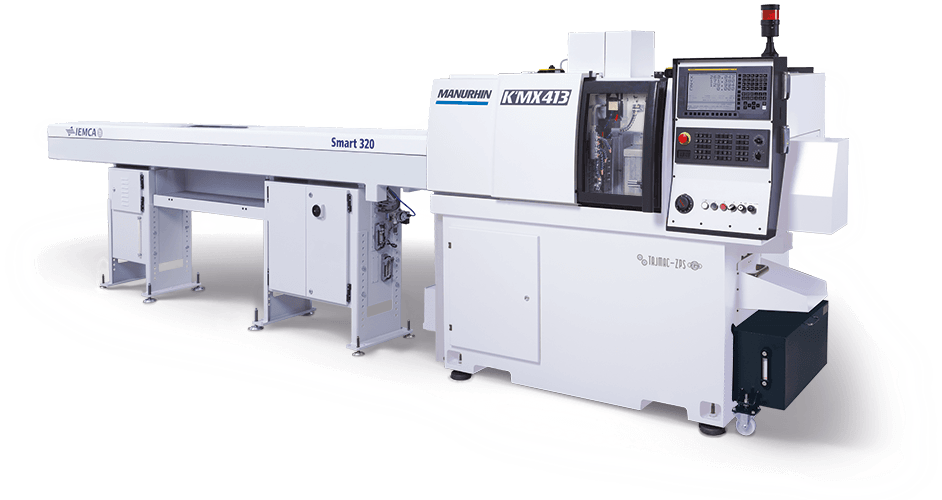

MANURHIN K´MX413

MORI-SAY TMZ867 CNC

MORI-SAY TMZ842 CNC

MORI-SAY TMZ642 CNC

MORI-SAY 832AC / 842AC

MORI-SAY 657AC, 667AC

MORI-SAY 632AC / 642AC

MORI-SAY 620AC

SPH 50 / D / DS

MASTURN

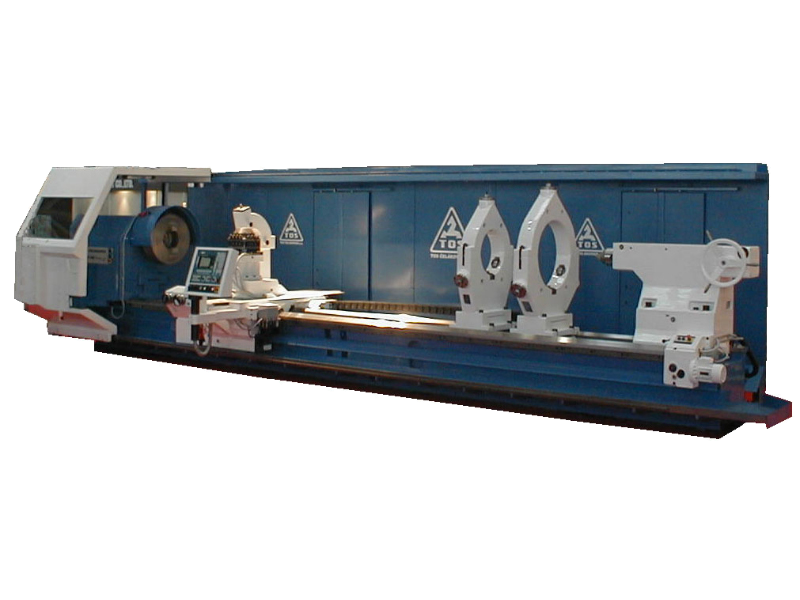

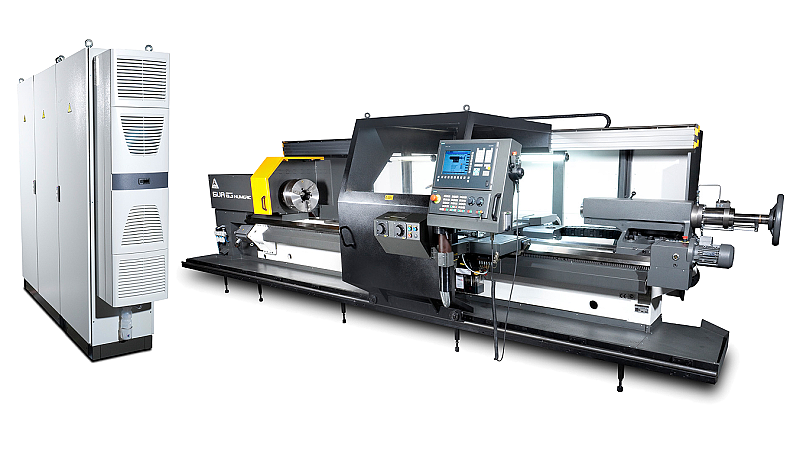

SUA 150 Numeric

SUA 125 Numeric

SUA 100 Numeric

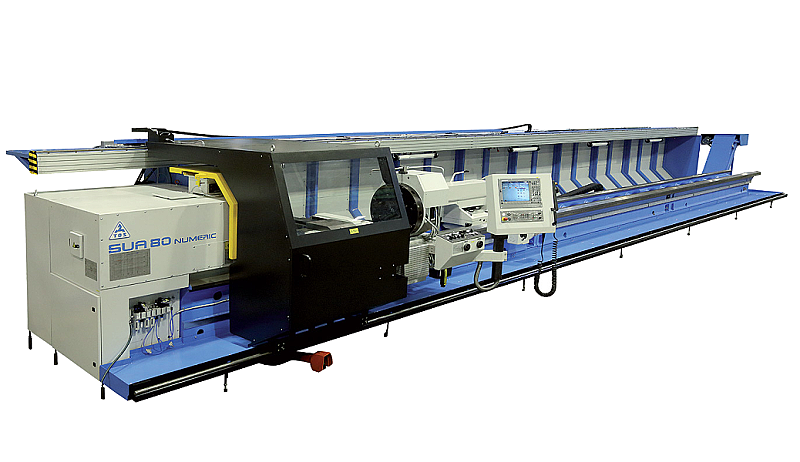

SUA 80 Numeric

SUA63 Numeric

SBX 500 CNC

SBE300 CNC

SBL 700 CNC

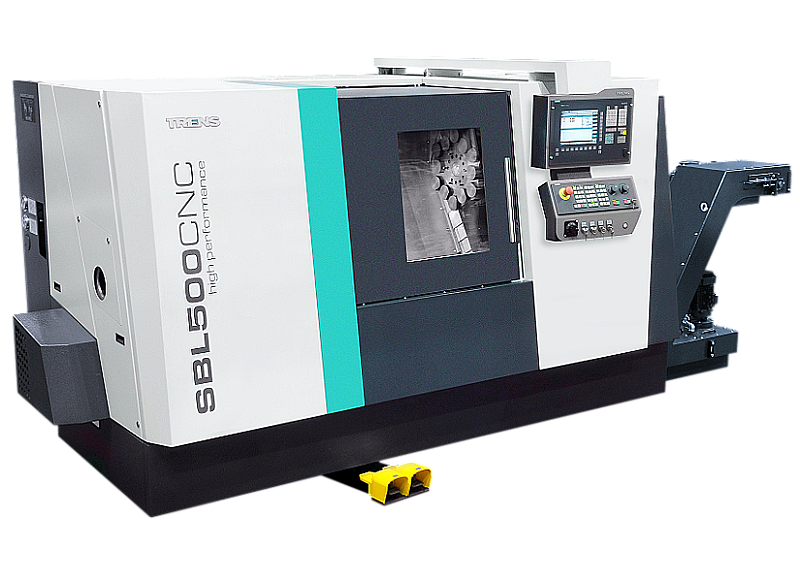

SBL 500 CNC

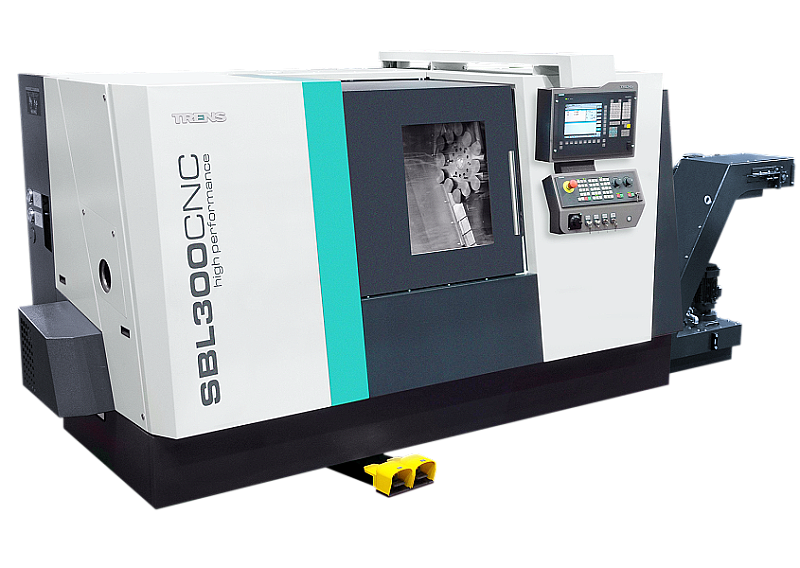

SBL 300 CNC

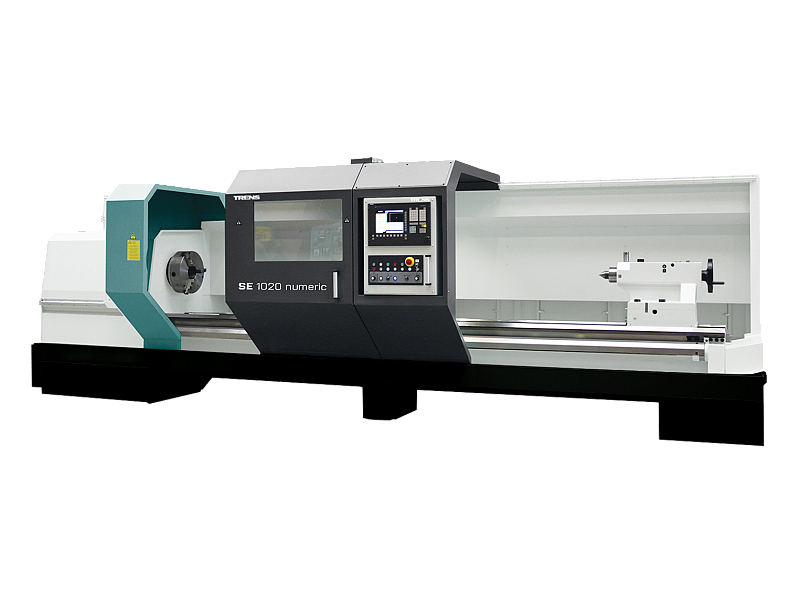

SE 1020 NUMERIC

SE 820 NUMERIC

SE 520 NUMERIC