Request

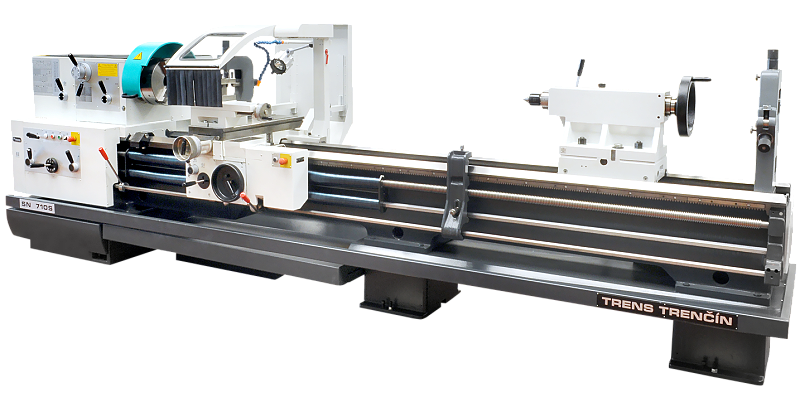

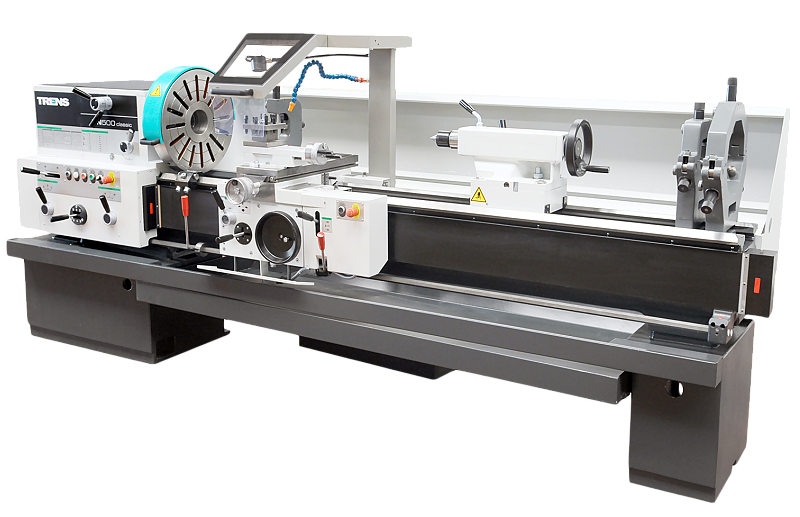

SN 710 CLASSIC

SN 710 CLASSIC is universal centre lathe designed for piece and small-lot production for turning workpieces of bigger dimensions. It is suitable for maintenance and repair divisions as well.

Universal small-lot production centre lathe SN 710 CLASSIC

SN 710 CLASSIC is universal centre lathe designed for piece and small-lot production for turning workpieces of bigger dimensions. It is suitable for maintenance and repair divisions as well.

Most important features:

- Designed for specific turning operations in gas, oil and water industries

- Easy maintenance

- Long lifetime

- Low operating costs

- Easy and ergonomic control

- Possibility to cut non-standard threads

- One-tooth clutch – comfortable thread cutting (SN 500)

- High turning precision

- Wide range of optional accessories – digital read-outs, quick change tool posts, steady and follow rests, rolling contact bearings for steadies, micrometric stops, taper turning attachements, faceplates and chucks

Optional executions:

- Quick change tool post

- Folding handles

- Different voltages and frequencies

- End switch for front chip guard (SN 500)

- Inch version

- CAMLOCK spindle nose

- Spindle bore 105 mm

- Spindle bore 130 mm (SN 710)

Basic execution:

- Metric execution

- Spindle nose Bayonet B8 (DIN 55027 & ISO 702-III)

- Spindle bore Ø 77 mm

- Four way tool post

- Electrics for 3 x 400 V / 50 Hz, circuit brakers

- Right hand handwheel

- Maximal swing in gap 700 mm in distance 230 mm from front of spindle nose

- Rapid traverse

- Tailstock

- Main motor output 7.5 kW

- Chip pan and coolant device

- LED lighting

- Uniflex cable carrier

- Reversing lever for apron direction movement during thread cutting

- Folding handle for X axis

- Folding handle for Z axis

- Chuck guard Ø 250 mm with safety switch

- CE execuion: with front chip guard, rear guard, lead screw and draw bar guard

- Colour – RAL 7035 / 7016 / 6153

- Set of exchange gears for cutting of threads

- 3 pcs of shear pin

- Operator kit

- Operator manual on CD, documentation

- Dead center Morse 5

- Reduction sleeve from Metric 90 to Morse 5

Special execution:

- Inch execution

- Inch execution USA/Canada

- Camlock spindle nose D8 (DIN 55029 & ISO 702-II), reduction spindle sleeve from Metric 90 to Morse 5

- Spindle bore Ø 105 mm Bayonet B11 (DIN 55027 & ISO 702-III), reduction spindle sleeve from Metric 115 to Morse 5

- Spindle bore Ø 105 mm Camlock D11 (DIN 55029 & ISO 702-II), reduction spindle sleeve from Metric 115 to Morse 5

- Voltage 3x 415V/50Hz, 3x 230V/50Hz, 3x 220V/60Hz, 3x 440V/60Hz

- Voltage USA/Canada 3x 575V/60Hz, 3x 440V/60Hz , 3x 220V/60Hz

- Quick change turret Multi Suisse C + toolholder CD 32150

- Safety switch for front chip guard

- Other colour execution than 7035 / 7016 / 6153

Does this model not meet your needs? We also have smaller option. More information to be found in our catalogue. The manufacturer reserves the right to change the product parameters and design without prior notice.