Request

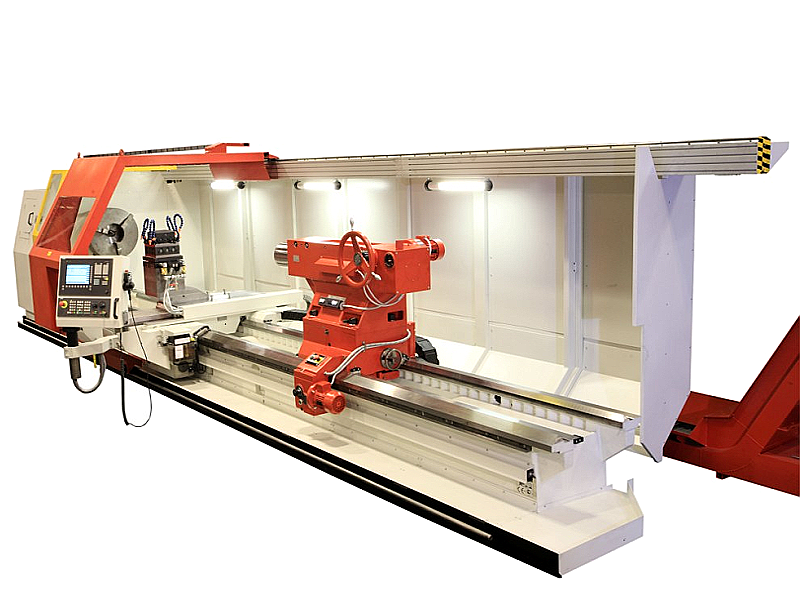

SBE300 CNC

SBE 300 CNC - slant bed lathe for performance turning of high precision flange and shaft shape workpieces. Proven machine design with high rigidity. Digital servo drives with ground ball screws and linear roller guideways with direct X-axis measuring. Reliability even in most demanding technological conditions.

CNC slant bed lathe SBE300 CNC

SBE300 CNC – slant bed lathe for performance turning of high precision flange and shaft shape workpieces. Proven machine design with high rigidity. Digital servo drives with ground ball screws and linear roller guideways with direct X-axis measuring. Reliability even in most demanding technological conditions. The machine in configuration with programmable tailstock and bar feeder is suitable for high performance and maximum turning productivity in mass production.

Most important features:

- CNC slant bed lathe for machining in two controlled axes

- High accuracy and reliability for continuous operation

- Modular machine conception – possibility to change machine options throughout its lifetime

- 30% energy saving – digital drives with energy recovery during braking

Basic machine configuration

- Voltage 3×400/50 Hz

- drives with energy recovery

- vector drive with AC main motor for spindle drive

- digital servo drives for working axes

- slides travel on linear roller guideways

- direct measuring of X-axis by linear scale

- C-axis (positioning of the spindle by main motor)

- automatic lubrication

- work area covers with safety glass

- complete tool cooling

- work area illumination by light with borosilicate glass

- control system SIEMENS available in languages: ENG, CYS, RUS

- setting of input and output parameters in metric/imperial units

- ethernet interface of the control system with RJ45 connector

- USB interface

- transporting device

- colour – RAL 7035 / 7016

- documentation on a CD

- “CE” execution

Configuration of the basic execution:

- Control system FANUC 0iTD ManualGuide i

- Distance between centers d.b.c. 500

- Turret without live tools with 12-position disc type Slotted Disc

- Spindle bore ø 65 mm with spindle nose DIN A2-6 (DIN55026 A & ISO702-I A2)

- Without spindle brake

- Spindle speed 4000 min-1

- Spindle power 11/15 kW (S1/S3-25%)

- Manual 3-jaw steel body chuck ø 200 mm; max. speed 4000 min-1

- C-axis (positioning of the spindle by main motor)

- Without tailstock

- Chip pan

- Electro cabinet ventilation – fans

- Coolant pressure 4 bar

- Tool probe – NO

- Parts catcher – NO

- Manual door opening

- Follow rest – NO

- Y-Axis – NO

- Z-axis measurement – Indirect measuring by motor encoder

- Preparation for bar feeder – NO

- Colour scheme Standard paint – 7035 / 7016

KL285

KL435

SE520 SL

SR1, SR2, SR3, SR4, SR5

MANURHIN K’MX 1032

MANURHIN K’MX 916 CLEVER

MANURHIN K´MX816 CLEVER

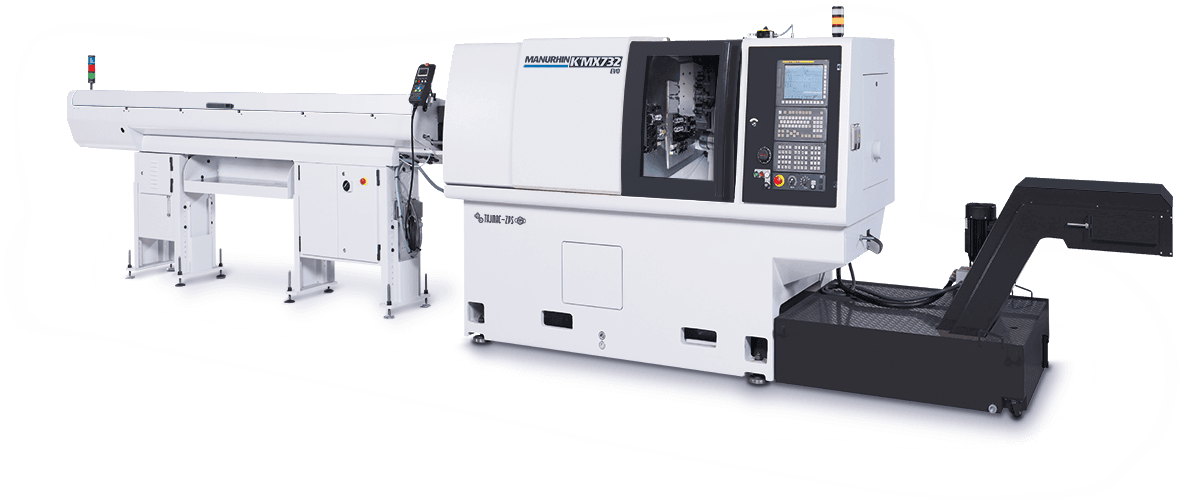

MANURHIN K´MX732EVO

MANURHIN K´MX632DUO

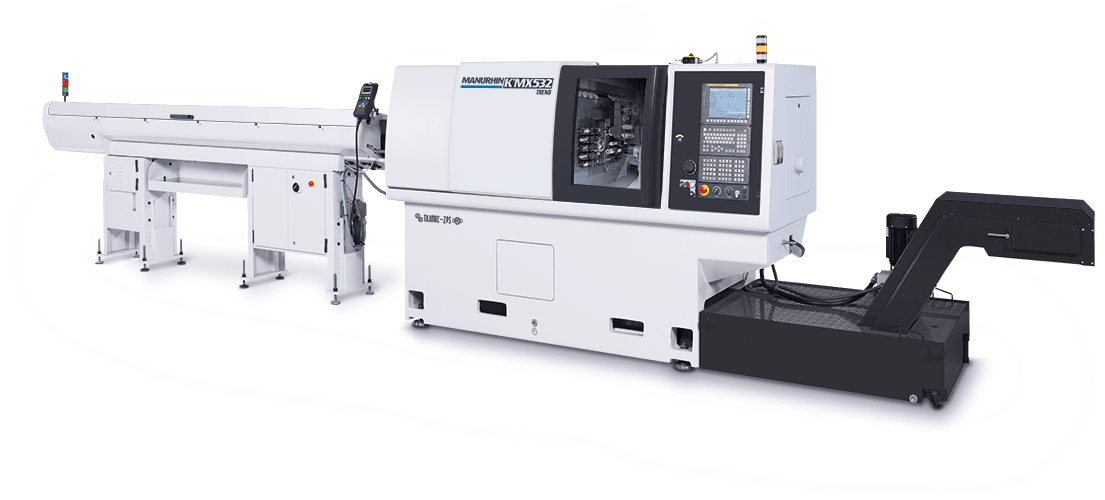

MANURHIN K´MX532 TREND

MANURHIN K´MX432

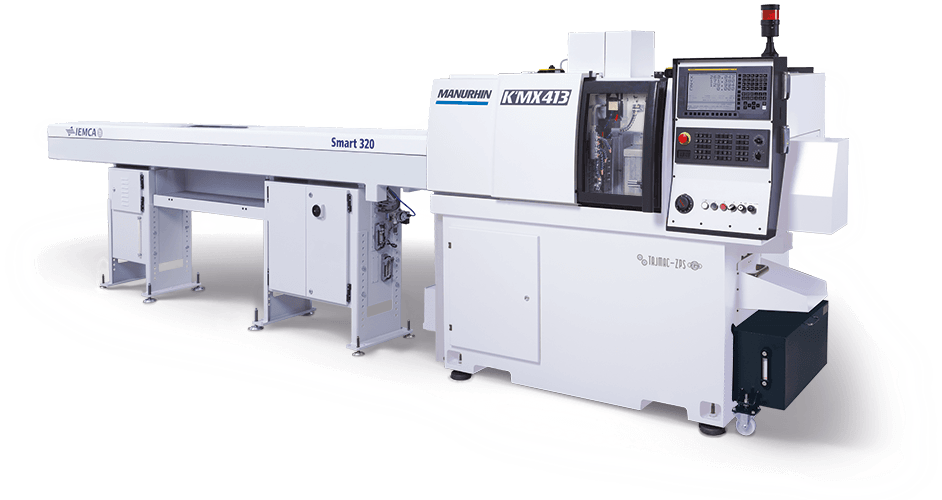

MANURHIN K´MX413

MORI-SAY TMZ867 CNC

MORI-SAY TMZ842 CNC

MORI-SAY TMZ642 CNC

MORI-SAY 832AC / 842AC

MORI-SAY 657AC, 667AC

MORI-SAY 632AC / 642AC

MORI-SAY 620AC

SPH 50 / D / DS

MASTURN

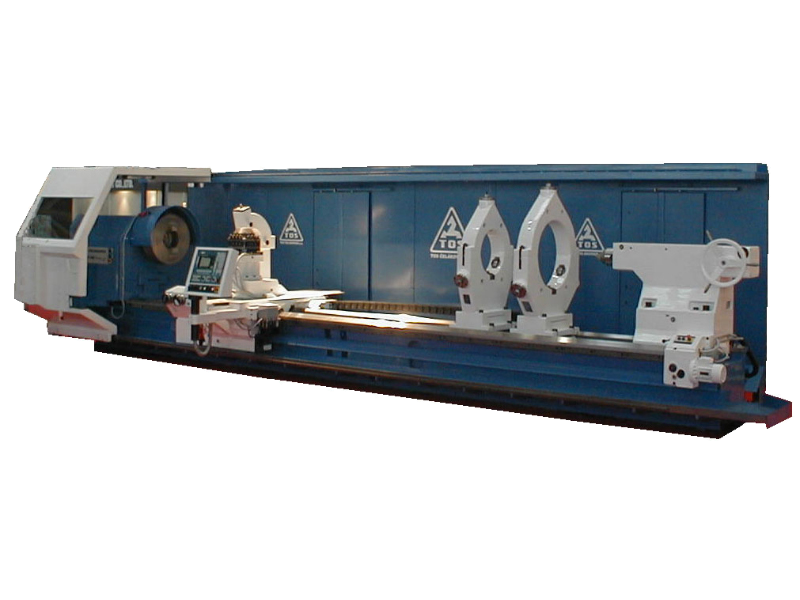

SUA 150 Numeric

SUA 125 Numeric

SUA 100 Numeric

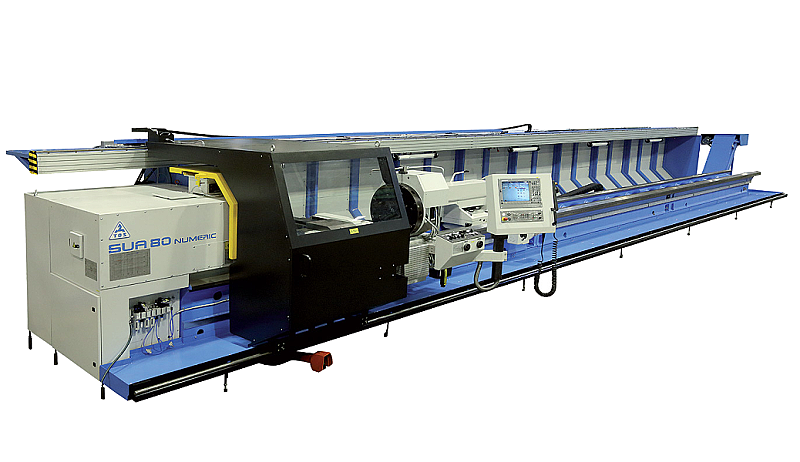

SUA 80 Numeric

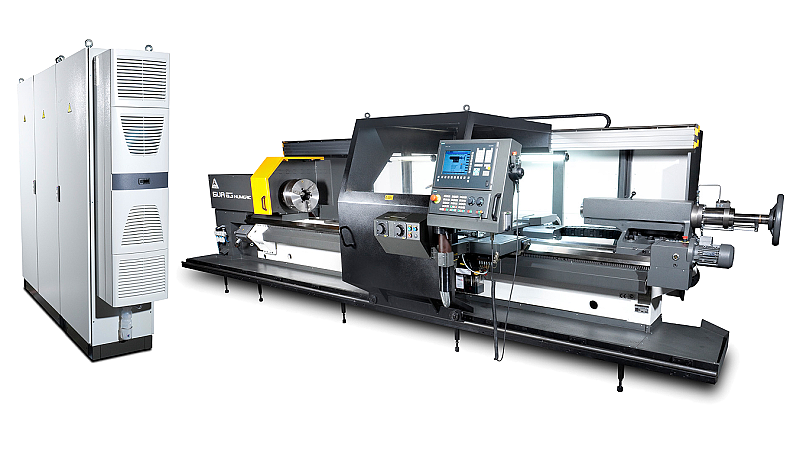

SUA63 Numeric

SBX 500 CNC

SBE300 CNC

SBL 700 CNC

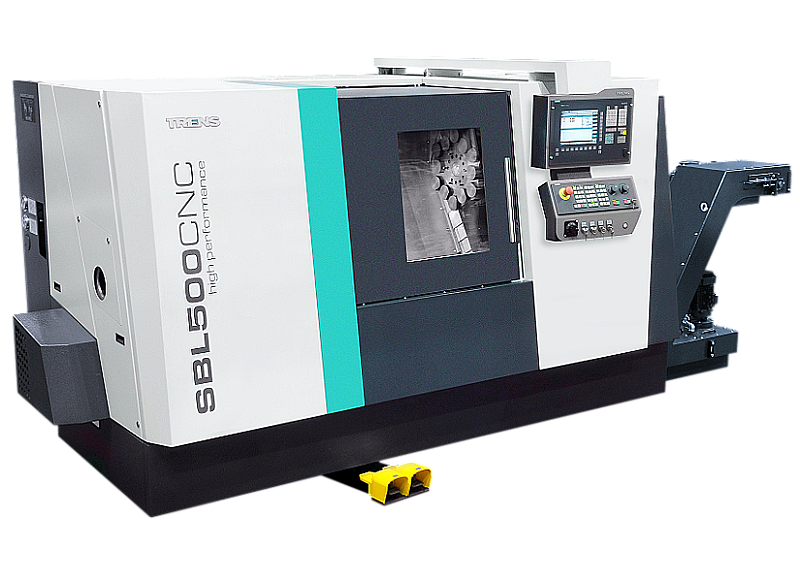

SBL 500 CNC

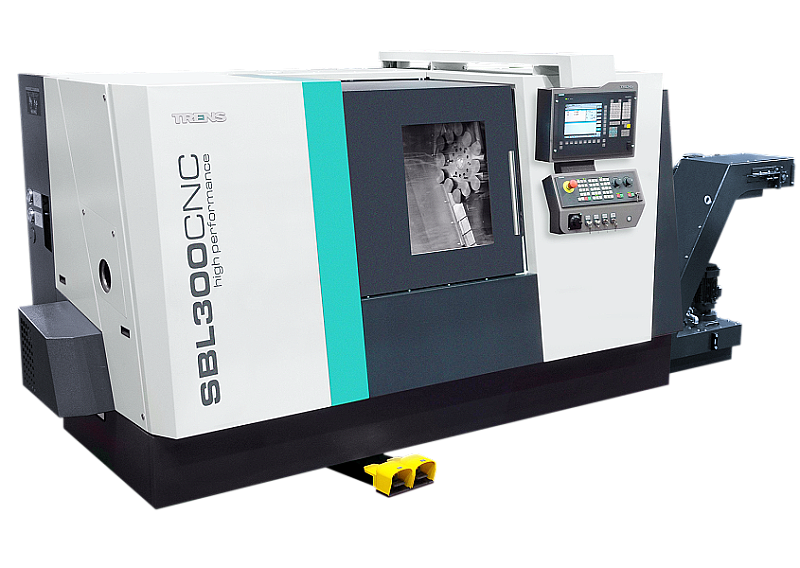

SBL 300 CNC

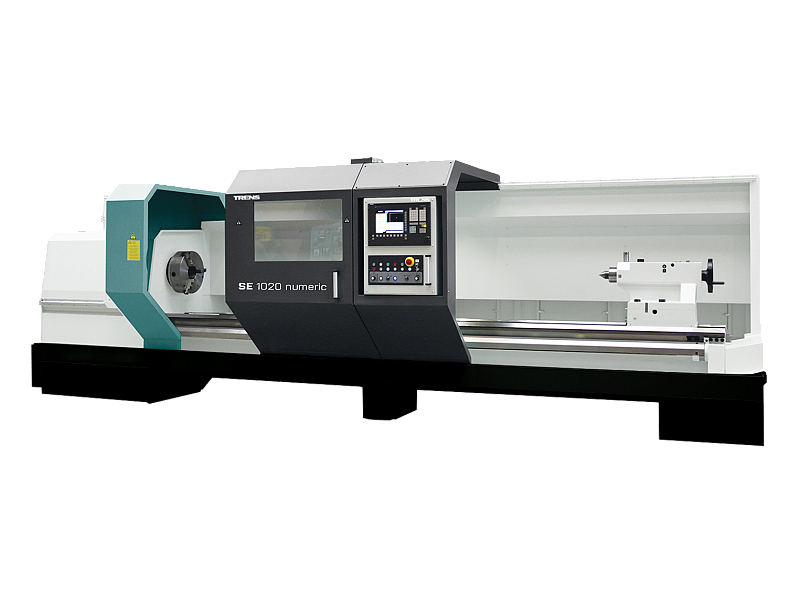

SE 1020 NUMERIC

SE 820 NUMERIC

SE 520 NUMERIC