Request

MC1040V

CNC vertical machining center is designed for machining flat and cabinet parts from all kinds of structural materials. It allows you to mill external and internal flat surfaces

CNC vertical machining centres MC1040V

MC1040V – CNC vertical machining center is designed for machining flat and cabinet parts from all kinds of structural materials. It allows you to mill external and internal flat surfaces, spherical surfaces and irregularly shaped surfaces. Of the technological operations, the machine is designed for milling, drilling, boring, reaming and threading. The machine is equipped with digital drives and direct measurement with linear rulers to achieve high precision when machining complex components.

The most important characteristics:

- The base of the machine is made of massive gray cast iron castings to achieve high rigidity and stability of the machine

- A large working range with a minimal layout of the machine

- Pre-tensioned linear rolling roller guide ensuring very precise positioning of work axes

- Hardened and ground ball screws for long-term accuracy throughout the life of the machine

- Clamping cone ISO 40 enabling the use of a wide range of technological tools

- HEIDENHAIN direct measurement in all axes guarantees dimensional stability and repeatable accuracy of workpieces

- Laser calibration of the machine during assembly

- HEIDENHAIN control system and digital drives

- Comfortable control of the machine thanks to the rotating fastening of the control system panel

- Electrical components from renowned European manufacturers

- Lossless grease lubrication of ball screws and linear guides

- Waterproof cabin covering of the work area with glass doors

- Clamping table with five grooves

- The design of the machine meets the latest safety standards and norms

- A wide range of additional accessories

MC1040V

MCG 1000

MCG 820

MCG 810

MCH 1000 FIVE AXIS

MCH 1000

MCH 800 Five Axis

MCH 800

MCH 630

MCV 1000 5 AX

MCU 1100V(T) – 5X

MCU 700V(T) – 5x

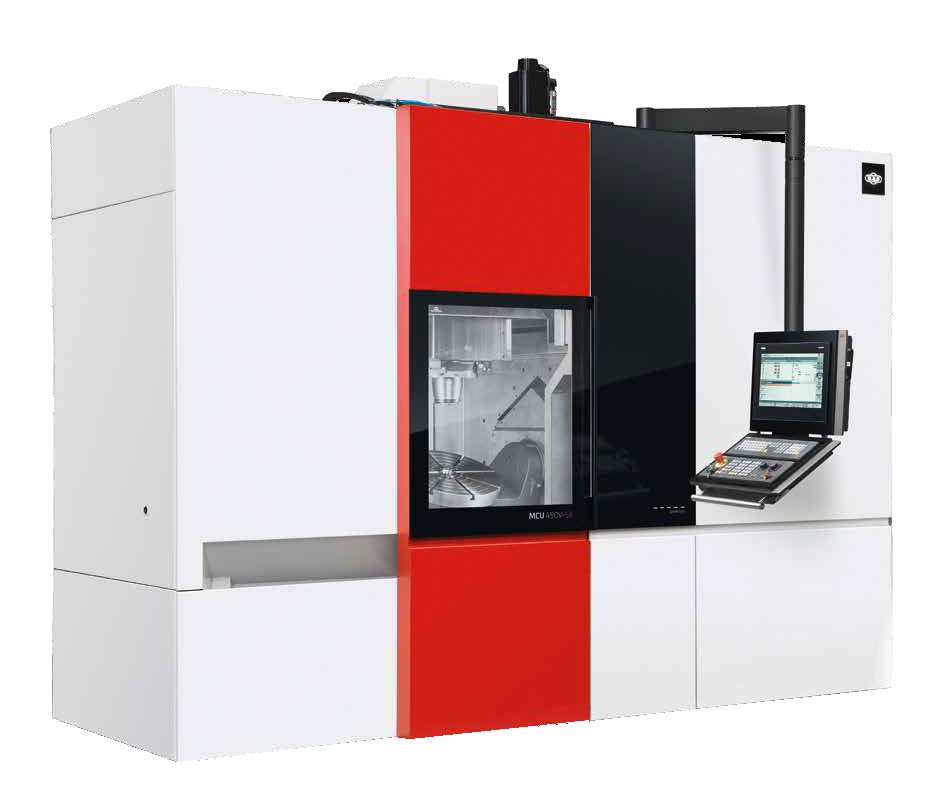

MCU 450V(T) – 5x

MCV 1016 Quick

MCV 1270 Rapid / Sprint / Speed / Power

MCV 800 Quick

MCV 754 Quick

MCV1000 Rapid / Sprint / Speed / Power

MCV 750

MCG 3022

MCG 2318

MCV 2080

MCV 1680

MCV 1260