Request

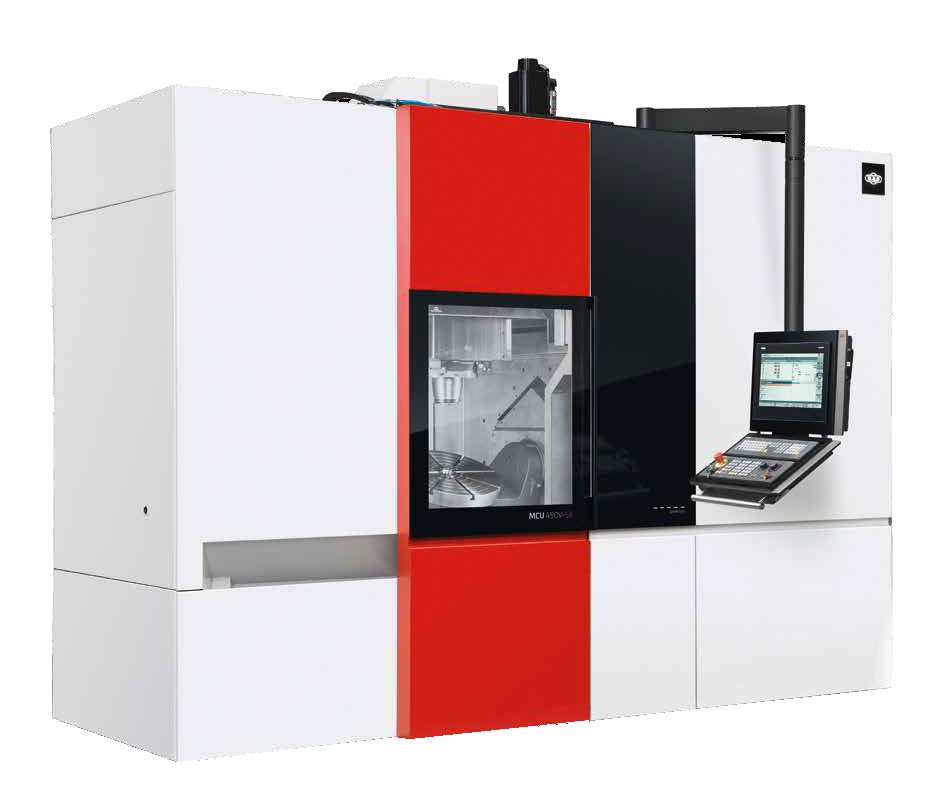

MCU 1100V(T) – 5X

MCU 1100 - Vertical upper gantry multifunctional center with wide technological utilisation like - continuous five-axis milling, turning, other technologies (drilling, boring, reaming, thread cutting).

Vertical machining centre MCU 1100V(T) – 5x

MCU 1100 – Vertical upper gantry multifunctional center with wide technological utilisation like – continuous five-axis milling, turning, other technologies (drilling, boring, reaming, thread cutting). All main elements of the frame are made of high quality cast iron which ensures unmatched rigidity, high damping and thermal stability.

Main application is found in the power industry in the production of water and steam turbines, impeller, stator and rotor blades, but also in the automotive, aerospace and engineering industries.

Fitting materials – steel, cast iron, ferrous and non-ferrous metal, plastics, wood, and graphite.

Machine Concept

- vertical gantry type center (upper gantry) with rotary and tilting table

- high rigidity thanks to a massive design made from grey and nodular cast iron

- symmetrical design

- active thermal stabilization

- moveable machine components (crossbeam, saddle, headstock) are located on roller linear guideways

- hydraulic or pneumatic ram balancing

- ram placed in the saddle with two sliding guideways for max. rigidity and damping

Drives of linear axes and measuring system

- direct measuring in all axes

- Y axis (crossbeam travel) in gantry mode, each drive has its independent measuring system

- automatic lubrication of all moveable parts

Rotary and tilting table

- symmetrical design

- direct drive by means of torque motor with direct absolute measuring in C axis

- flow cooling of C axis drive

- tilting A axis with mechanical drive in both sides (gantry), high-accurate ground bevel gear with curved gearing

- rotary table axis with endless rotary angle

- hydraulic clamping for indexing of machining in all three drives

- possible palette changing system

- hydraulic clamping of the palettes by means of 4 precise clamping pins

Spindle units

- spindle units with integrated drives

- flow (circulation) spindle cooling

- centric tools clamping

- outer cooling of tools – with coolant or with air

- high pressure internal tool cooling – with coolant or with air

- bearings with automatic lubrication or with Lifetime filling

Warning: Invalid argument supplied for foreach() in /data/1/8/1843503e-8530-4c63-aea5-fd8894436569/strojimport.com/web/wp-content/themes/strojimport/single.php on line 98

MC1040V

MCG 1000

MCG 820

MCG 810

MCH 1000 FIVE AXIS

MCH 1000

MCH 800 Five Axis

MCH 800

MCH 630

MCV 1000 5 AX

MCU 1100V(T) – 5X

MCU 700V(T) – 5x

MCU 450V(T) – 5x

MCV 1016 Quick

MCV 1270 Rapid / Sprint / Speed / Power

MCV 800 Quick

MCV 754 Quick

MCV1000 Rapid / Sprint / Speed / Power

MCV 750

MCG 3022

MCG 2318

MCV 2080

MCV 1680

MCV 1260