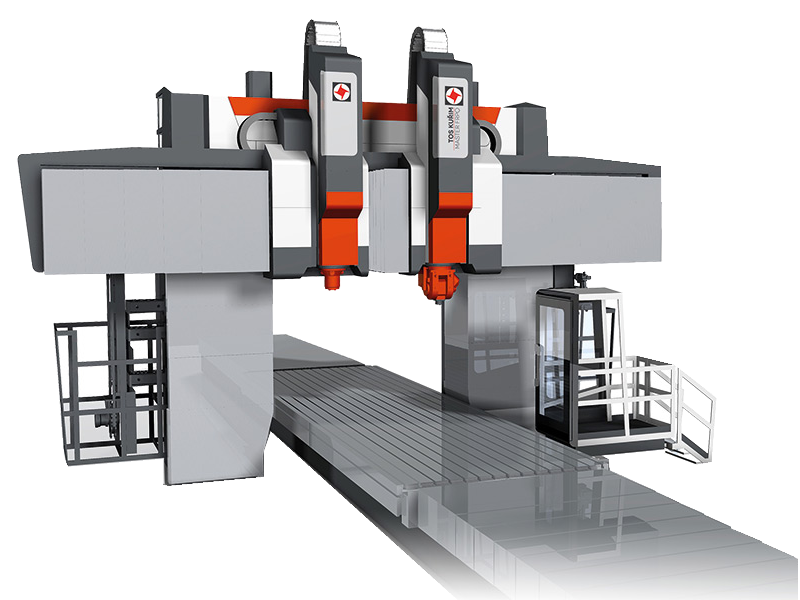

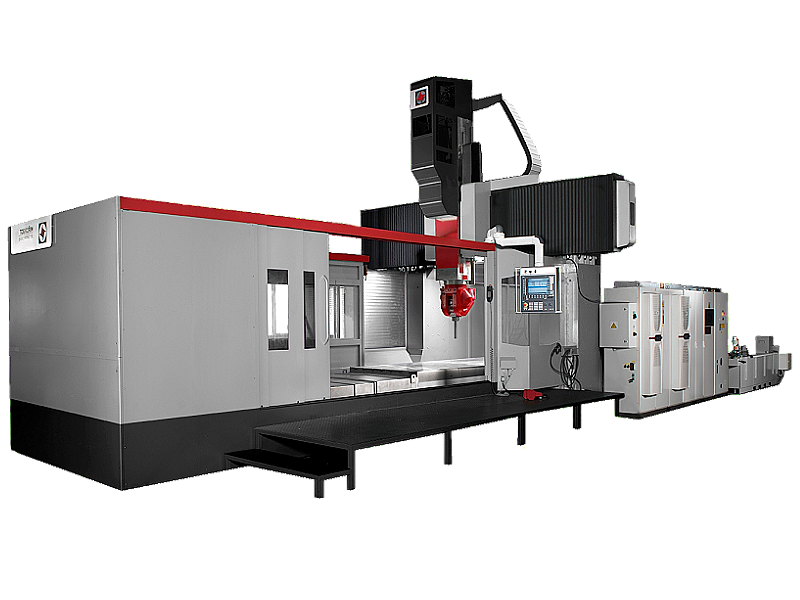

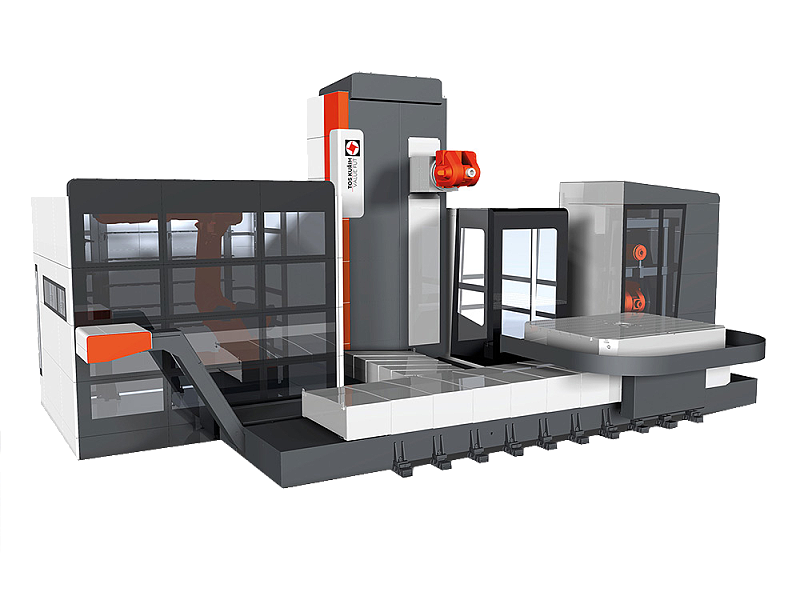

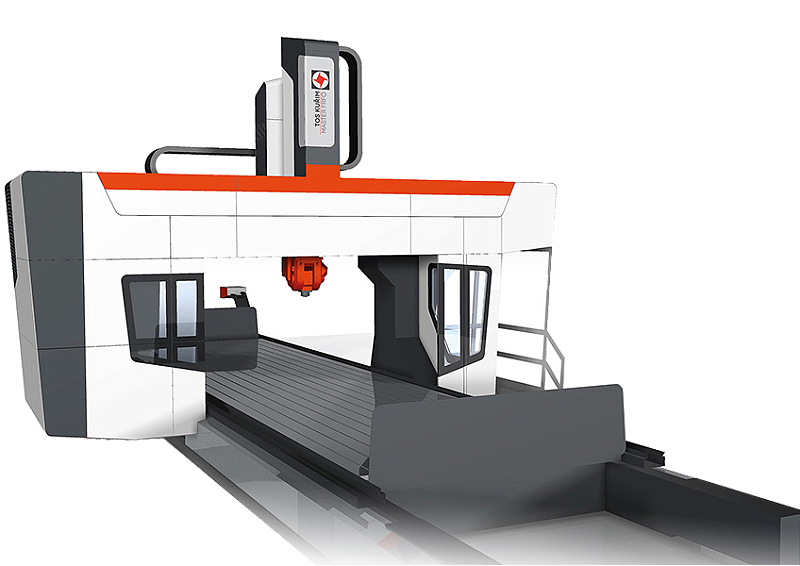

FRP

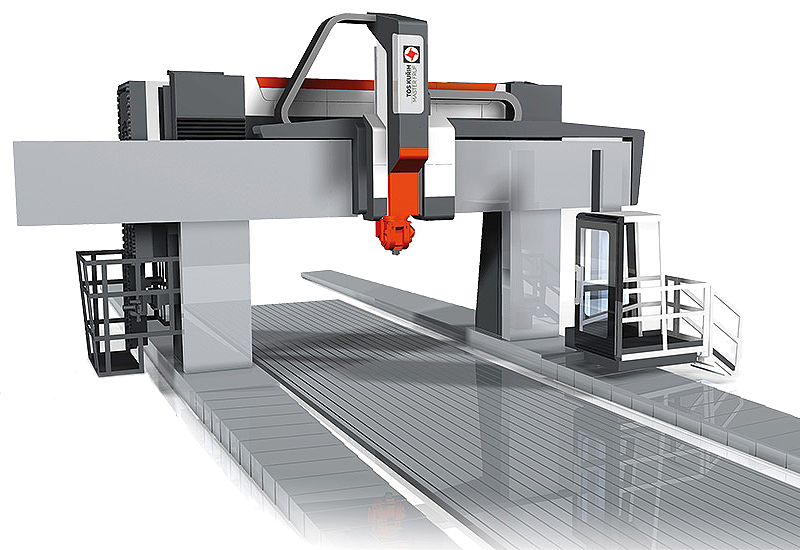

Gantry centre FRP

The FRP gantry centre is designed for standard or high-speed machining of large and very complex workpieces. It consists of a bed on which the table is shifted and a fixed gantry with a movable cross-rail. Customers can choose between a linear and hydrostatic guide way.

FRP also allows turning, which is possible thanks to an optional VTL table. The machine is equipped with versatile spindle heads, which allow a variety of machining operations. The customers choose it for machining aircraft engines, locomotive diesel engines or steam turbine casings. Thanks to its high performance and torque, FRP can also be used for roughing operations.

Main benefits:

- modern optimized composite solution of major parts of machine

- fixed portal, movable table

- fixed or movable cross–rail

- thermal stabilization of headstock and exchangeable spindle heads

- hydrostatic or roller guideways of linear axis

- automatic exchange of spindle heads and tools

- axial tool cooling

- spindle 4 000 (6 000) rpm with high torque

- rapid feed up to 30 m/min

- machining of large and heavy workpieces

Machine description:

Table and bed

The table is made of a ribbed casting. The upper table surface is furnished with crosswise clamping T-slots. The table is mounted on roller bearing elements.

The bed consists of firmly mutually unitized castings that are fitted with profiled gibs on its top part. Guideways are protected by telescopic metal guards.

Columns

The columns are rigid ribbed castings firmly fixed to the machine base, on the top they are furnished with surfaces for mutual connection with the crossrail.

Crossrail

The crossrail is a cast-iron casting which, firmly connected with the columns, forms an interconnected portal. On the front vertical part the guideway crosswise guides are furnished with linear roller bearing profiled gibs to guide the cross slide.

Cross slide

The cross slide is a casting with a complicated shape in its rear vertical part furnished with spring-loaded roller bearing elements making up a guideway enabling the cross slide to move on crossrail guideways. There are guideways for headstock travel in the front vertical part, the guideways consist of preloaded linear roller elements.