FUT

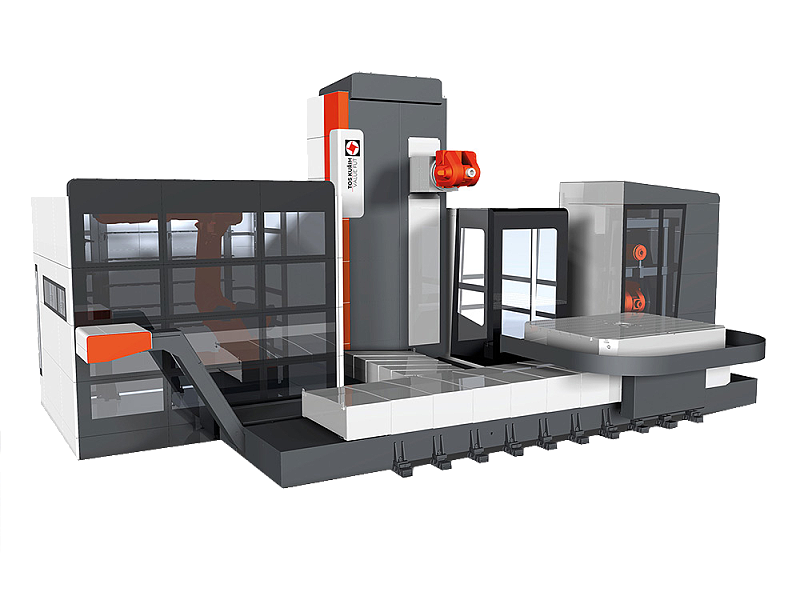

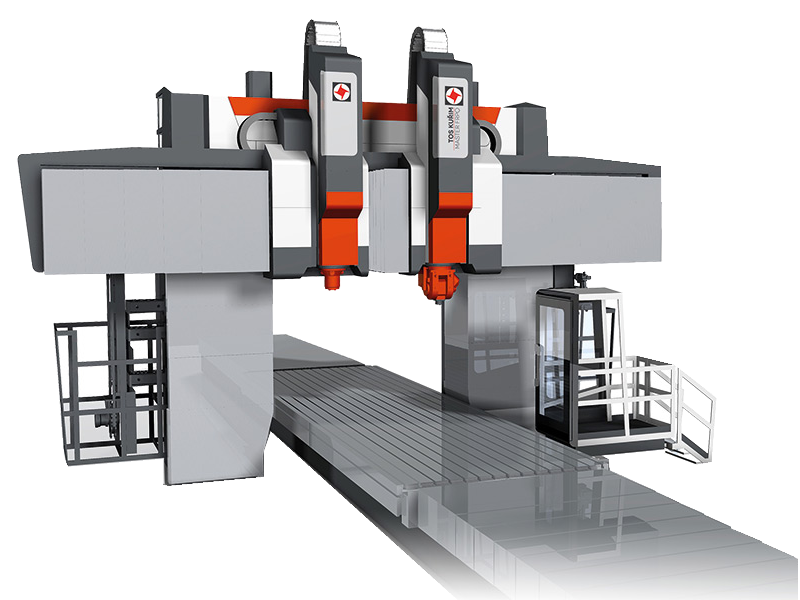

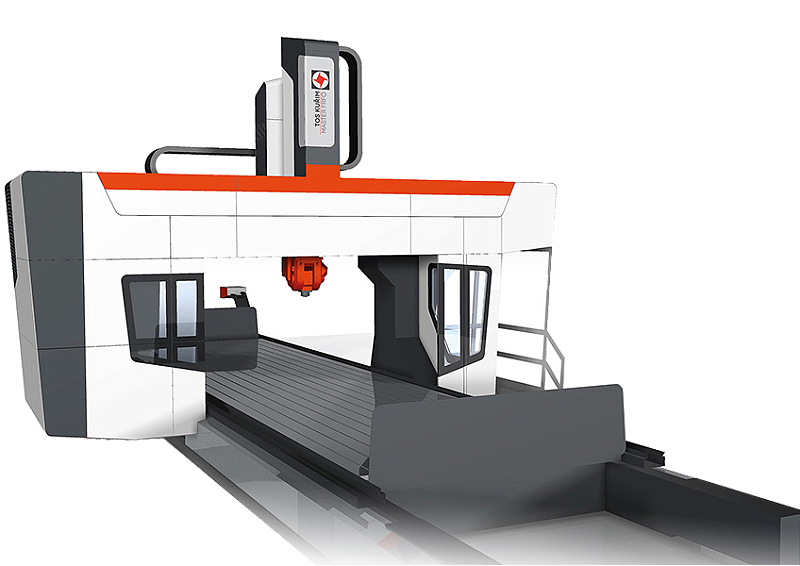

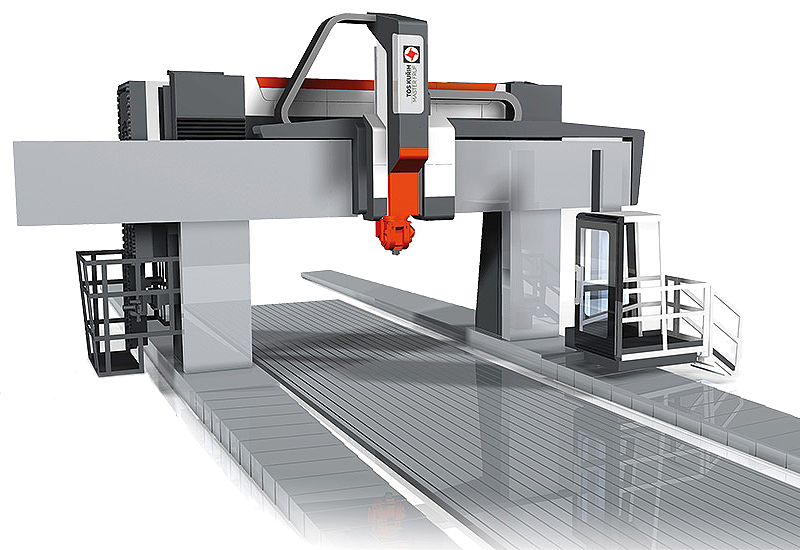

Horizontal machining centres FUT

Horizontal milling machine is designed for machining of complicated workpieces with respect to jobs hape by both classical milling technology and high speed machining implementation.

Milling machine base structure is designed as individual longitudinal and cross bedin T-shape design feature. Longitudinal slide unit (so called sledges) moveable in X axis (longitudinal direction) alongside the fix bed surface. Upper longitudinal sledges surface is designed with rotary positioning table. Milling machine column is movable in Z axis (cross movement direction). Head stock moves alongside column guide surfaces in Y axis /vertical movement/. Possible shift-out executionin W axis.

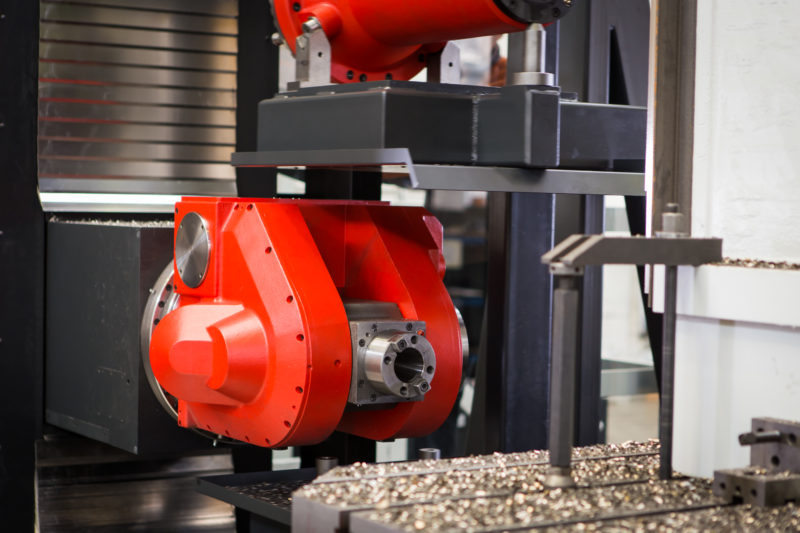

Milling machine technological versatility with main respect to possibility of milling attachment selection enables the machine maximal utilization and adaptation for wide range of technological requirements. There is optimal way to choose type of concrete milling head ready for machining of specific operation with possible utilization of maximal level of cutting conditions and utilization of milling machine working area. High milling machine cutting performance / cutting power and high level torque values on m/c milling attachments available with mechanical spindle drive should be implemented during rough milling effectively.

The machine is in basic configuration designed for working with parameters given by file of combination of classes ambient conditions IE 33, according to ČSN EN 60721-3-3:1997, A2:1998, but air temperature must be within +15°C up to 35°C and air pressure higher than 90 kPA.

For reaching of an optimum working accuracy should be reached following conditions:

- Ambient temperature within +17°C up to +25°C

- Change of ambient temperature within 24 hours less than 4°C

- Temperature change gradient less than 0,5°C/hour

Main benefit

- modern optimized solution of machine bed and column

- rapid feed up to 30 m/min

- thermal stabilization of headstock and exchangeable spindle heads

- linear roller guideways in linear axes

- automatic exchange of spindle heads and tools

- axial tool cooling

- spindle 4 000 (6 000) rpm with high torque

- machine on flat foundation