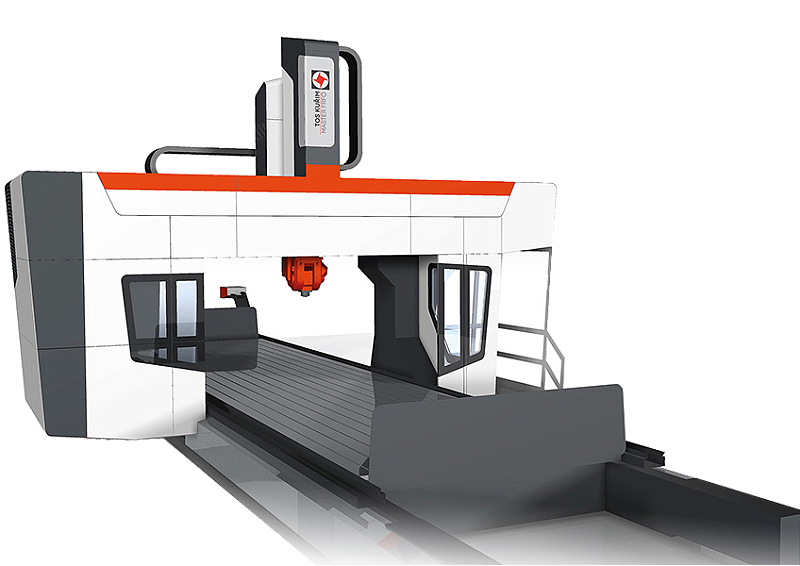

FRF

Gantry Machining Center FRF

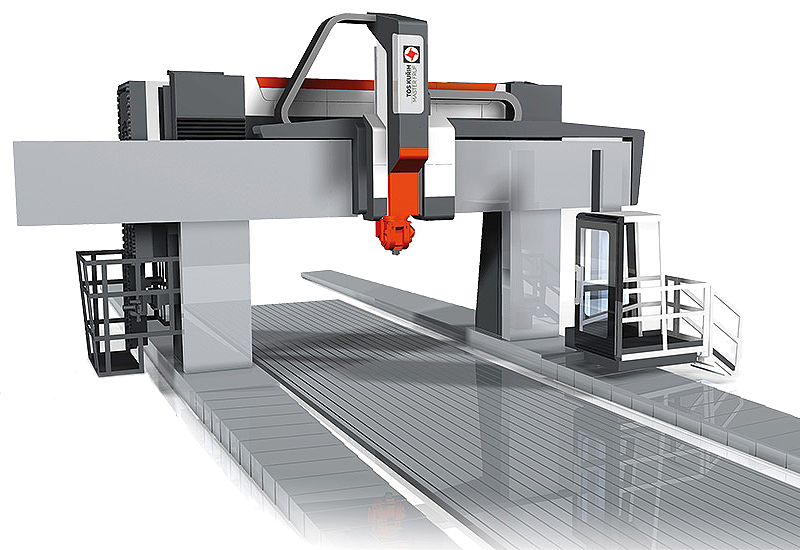

The gantry machining center FRF is specified especially for milling of complicated shapes in manufacture of moulds, press tools, dies or of workpieces having very complicated shapes and sizes which require machining with five continuously controlled axes, three linear axes and in two rotary axes.

The machine parameters enable you to machine a wide range of materials, including alloy steels and light metal alloys.

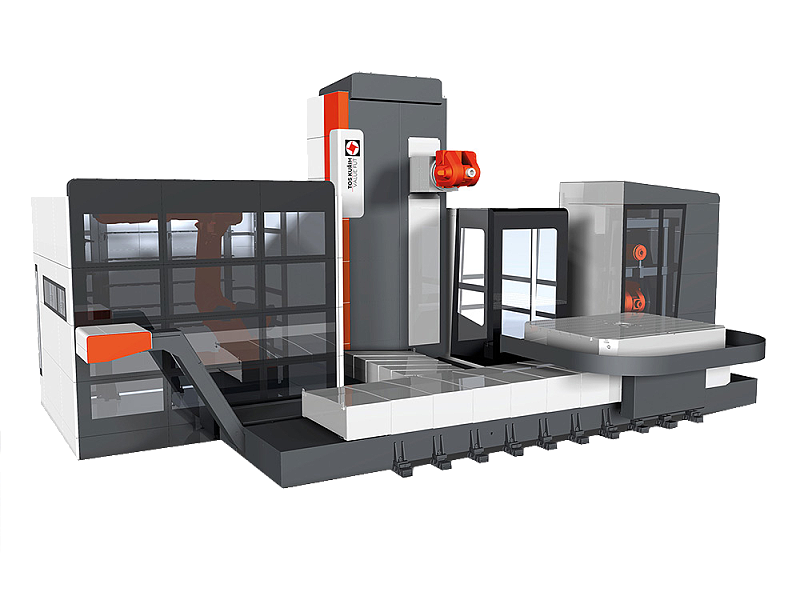

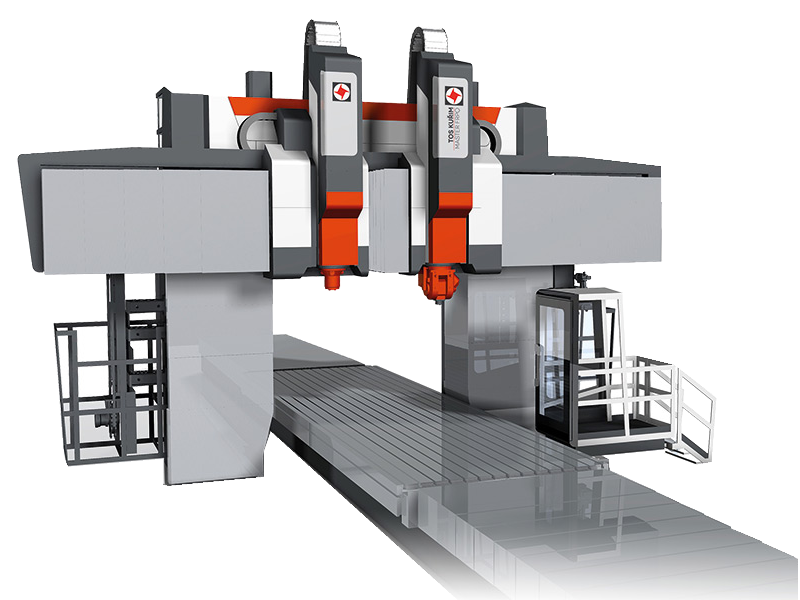

The basic machine feature is represented by the fixed table. The gantry consisting of two columns connected with the fixed cross rail moves along on both table sides. This arrangement enables a considerable utilization of the working area together with the minimum requirements on the built up surface.

The machine is equipped with a vertical headstock having the mechanism for automatic clamping of exchangeable spindle heads or it is equipped with the headstock having a non exchangeable head.

In its basic configuration, the machine is determined to work in the working area with the parameters given by the set of the combination of ambient condition classes IE 33, according to ČSN EN 60721-3-3:1997, A2:1998; however, the air temperature must range from +15 °C to +35 °C and the air pressure must be more than 90 kPa.

To reach the optimum working accuracy, the following conditions must be kept during machine operation:

- Ambient temperature within +17 °C up to +25 °C

- Change of ambient temperature during 24 hours less than 4 °C

- Ambient temperature change gradient less than 0,5 °C/hour

Table specification:

The base of the working area is the working table which serves at the same time for the column travel. The table consists of a cast iron casting and its upper part is machined for the part clamping surface equipped with T slots serving for workpiece clamping. The table consists of sections which are connected together in the required length. Due to its design and the anchorage system, the table enables clamping complicated and heavy workpieces with large dimensions. The hardened strips of the longitudinal guideways are attached to both side surfaces of the table casting. The longitudinal X axis is covered by means of telescopic protective guards mounted on the table and on the column.