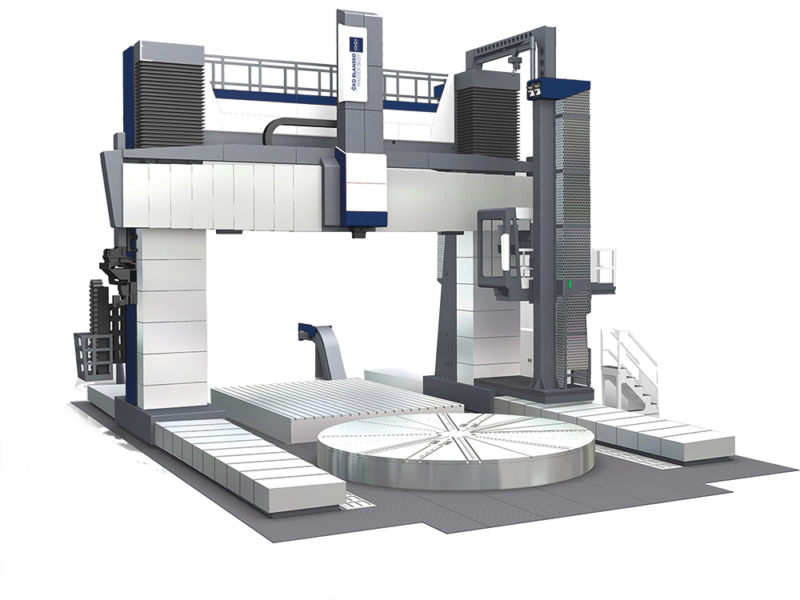

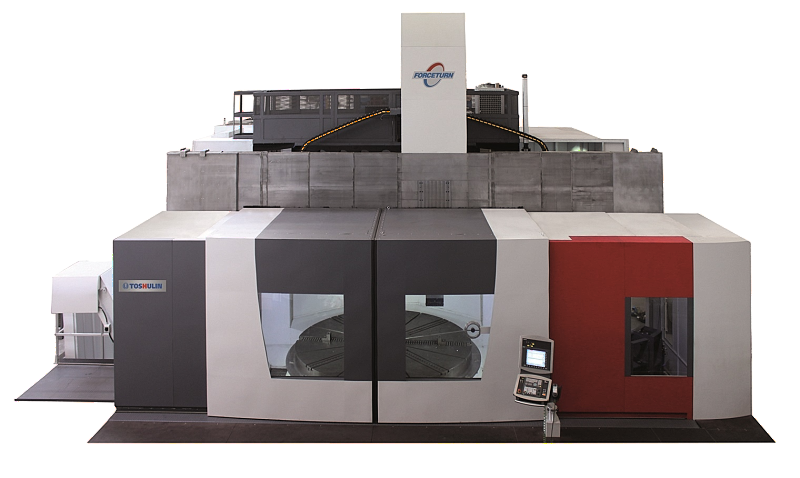

BASICTURN

Vertical turning lathe BASICTURN

BASICTURN – is traditional vertical lathe and vertical machining center based on years of experience with the implementation of state-of-the-art solutions manufactured by TOSHULIN JSC. The vertical turning lathes preference is very stable construction and precision machining of the 1250 to 4000 mm diameters, precisely according to the customer’s individual needs – even in the most demanding applications. The machine can integrate various chip machining technologies like turning, but also milling, grinding or drilling. The machine can be fitted with a Siemens or Fanuc control system. All vertical turning centers from TOSHULIN a.s. can be equipped with remote machine diagnostics, which helps with the customer diagnosing and correcting most faults of the machine. This is the fastest possible way of detecting the cause of a fault on a machine (80-90% efficiency in solving the problem). A wide sortiment of accessories and extras.

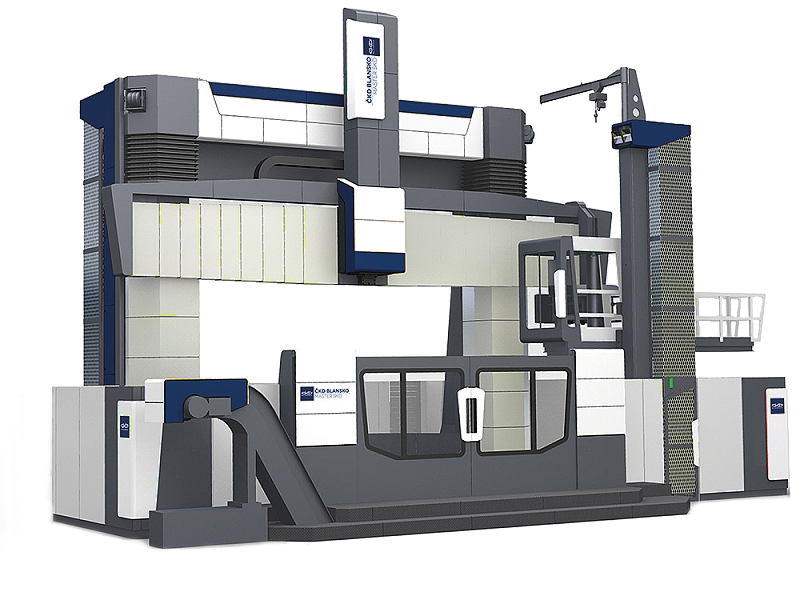

- Frame with high rigidity and stability

- Design emphasizing functionality and easy maintenance

- Control systems Siemens or Fanuc

- Pre-defined configuration enabling quick machine delivery

- Possibility to equip the machine with table positioning (C-axis) and with the rotary tool drive

- Automatic exchange of turning tools and rotary tools

- Variable height of the working area

- Ram designed for efficient and precise machining

- Possibility to perform high-pressure through the tool coolant

- Up-to-date and user-comfortable operation

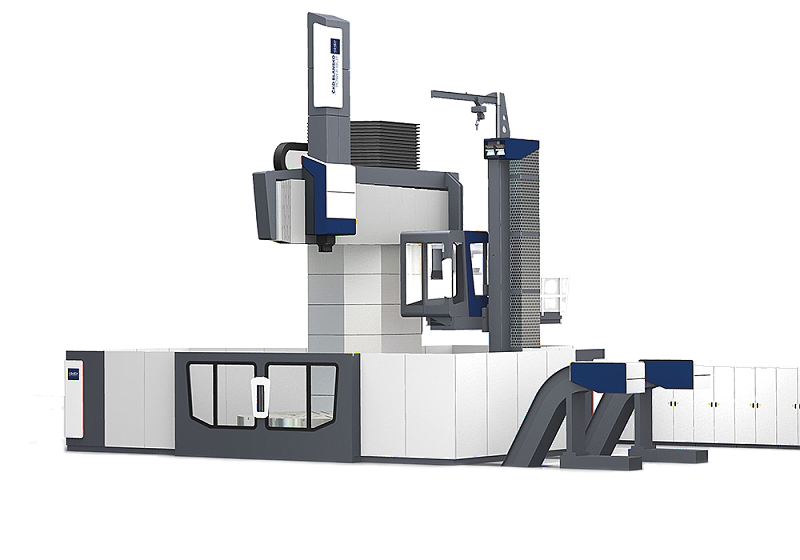

Machine Frame

Made of cast iron. One column securely mounted and attached to the table base. Thermo – stable design; build up table base and the main drive centrally located relative to the column.

Table Base

Made of cast iron. Table bearing system with preloaded bearing. Table oriented stop with the main drive motor operating as a servo unit.

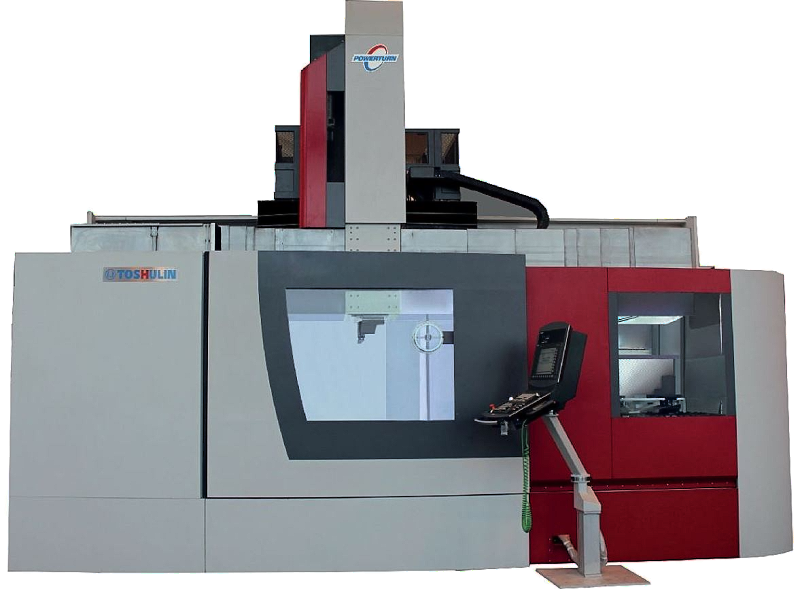

Main Drive

Two – speed planetary gearbox, motor mounted vertically on the table base, remote controlled. Hardened and ground driving pinion. Infinitely variable speed in 2 auto shifted gear steps at a constant power and a constant torque. CW and CCW table rotation.