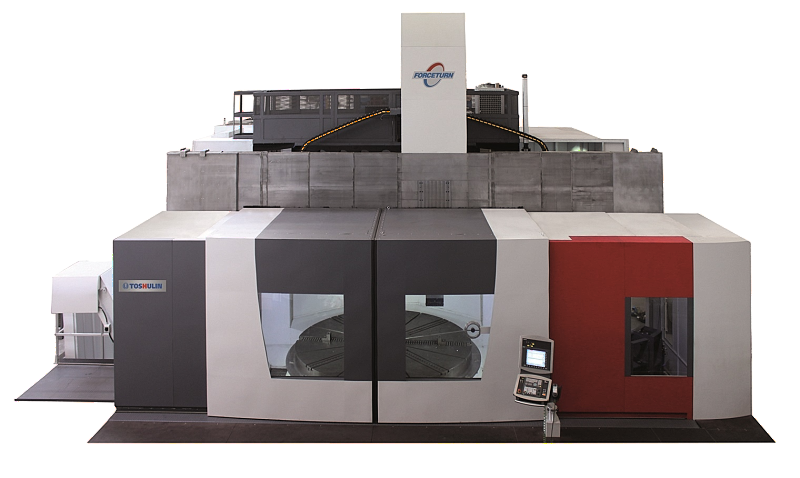

FORCETURN

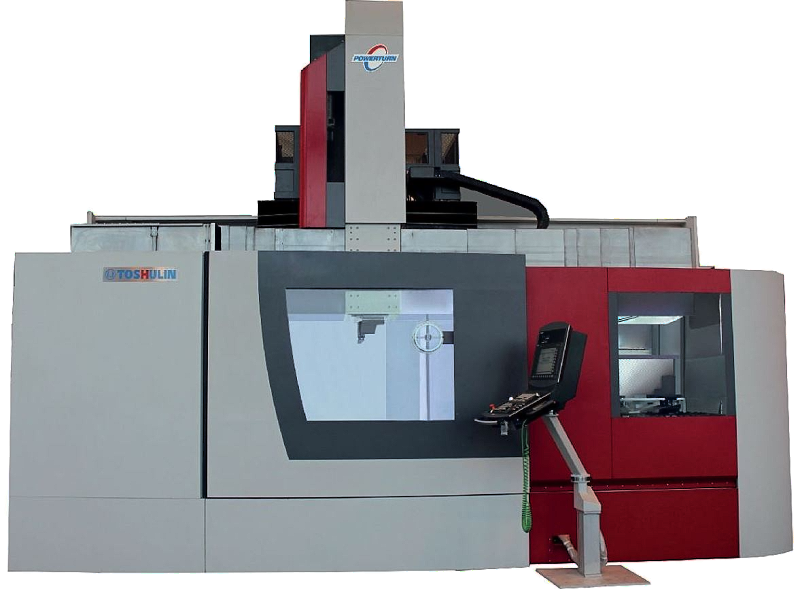

Vertical turning lathe FORCETURN

FORCETURN – is traditional vertical turning lathe and vertical machining center based on years of experience with the implementation of state-of-the-art solutions manufactured by TOSHULIN JSC. The vertical turning lathes preference is very stable construction and precision machining of the 2500 to 4000 mm diameters, precisely according to the customer’s individual needs – even in the most demanding applications. The machine can integrate various chip machining technologies, including turning, milling, grinding or drilling. The rigid cast iron construction of the bed, cross rail and column makes it suitable for high accuracy work as well as very heavy duty turning and milling.

As a result of a unique 65- years tradition and know-how in designing and building Vertical Turning Machines, combined with integrating advanced electric and electronic components made by Siemens or Fanuc, TOSHULIN provides to its valued customers a superior quality machines with a proven long lasting accuracy and reliability. All vertical turning centers from TOSHULIN a.s. can be equipped with remote machine diagnostics, which helps with the customer diagnosing and correcting most faults of the machine. This is the fastest possible way of detecting the cause of a fault on a machine (80-90% efficiency in solving the problem). A wide sortiment of accessories and extras.

Machine Frame

Made of cast iron. One column securely mounted and attached to the table base. Thermo-stable design; build up table base and the main drive centrally located relative to the column.

Table Base

Made of cast iron. Table bearing system with preloaded bearing. Table oriented stop with the main drive motor operating as a servo unit. Thermal stabilisation of the table by means of lubrication oil cooling unit.

- High-performance work in large dimensions

- Possible machining of high and heavy workpieces

- Highly stable frame made from the cast iron for high-performance machining

- Possibility of high-pressure cooling

- Wide variability of instrumental equipment

- Premium range is in the X axis in both directions from the center of the clamping plates

- Effective coverage of the machine to prevent spattering of the coolant