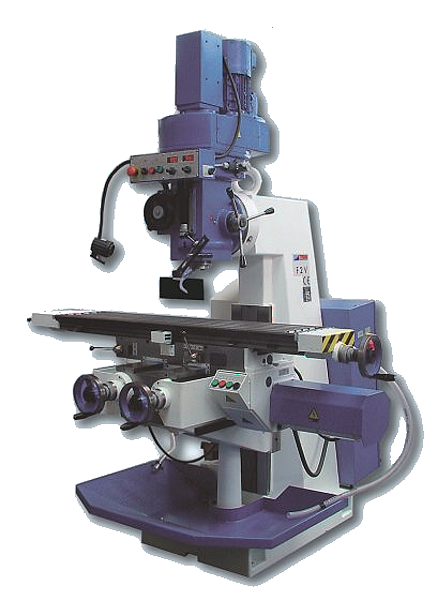

FNG 50 CNC A

Continuously controlled milling machine FNG 50 CNC A

FNG50 CNC A – is continuously controlled tool-room milling machine designed to cover a wide range of milling, drilling, boring and thread cutting operations on workpieces up to 350 kg weight. This machine is especially suitable for tool-making workshops. The machine is equipped with horizontal spindle which is fitted in the ram-type spindle head and also with vertical milling head which can be tilted in the range ±90°. The machine is delivered with vertical milling head , swing away arm for this head (Special execution) and fixed angular table. The perfect clamping of tool is realized by pneu-hydraulic clamping in both vertical and horizontal spindle. Spindle drive is by means of electromotor with stepless regulation of revolutions. The stepless spindle speeds are divided into 2 steps in range 50-4000 r.p.m. The optimum lubrication of guideways is solved by means of lubriction pump with dosing devices. Cooling equipment of tools, working light and working space guard are delivered as standard accessories.

Advantages:

- Horizontal and vertical spindle

- Modern design and perfect surface finish with oil-resistant painting

- Stepless spindle speeds by means of frequency convertor in 2 steps

- Full output of the spindle from 450 r.p.m.

- Direct measure system in 3 axes

- Pneu-hydraulic tool clamping

- Hardened guideways, mating faces are covered with TURCITE

- Simple and confortable operation, compact layout

- Central lubrication by means of dosing devices

- Wide range of technological possibilities

- High rigidity, accuracy and reliability of the machine

- Efficient working space guard

- Easy maintenance

Standard execution:

- Control system HEIDENHAIN TNC 320

- Fixed angular table 900 x 500 mm

- Vertical milling head

- Frequency converter in the spindle drive (asynchronous motor)

- Pneumatic-hydraulic tool clamping

- Central lubrication with dosing devices

- Tool cooling equipment

- Electrical equipment for 3 x 400V/50 cycles

The manufacturer reserves the right to change the product parameters and design without prior notice.

FGV32

FGU32

F2V/R

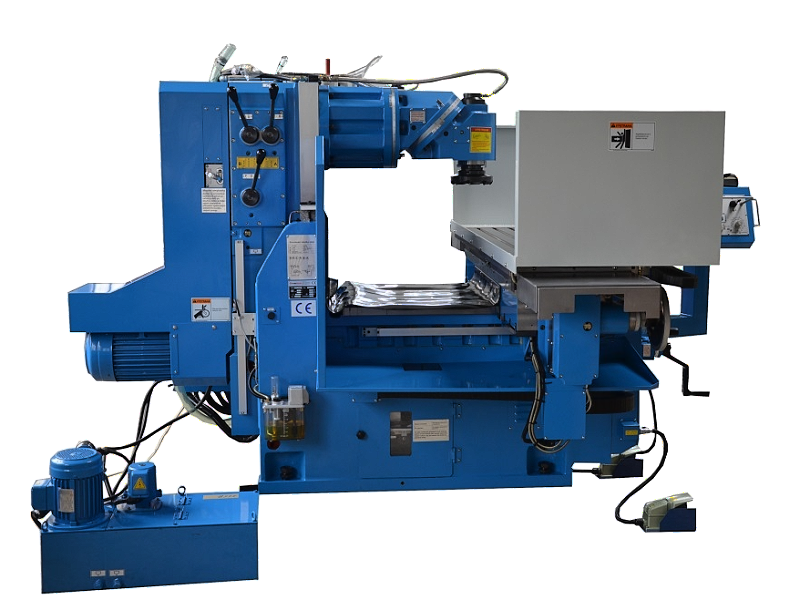

FU

FUT

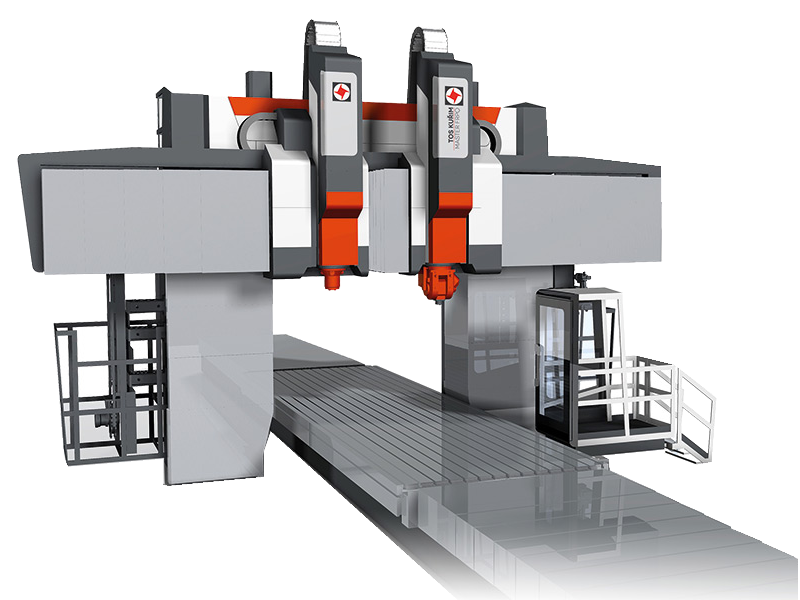

FRP

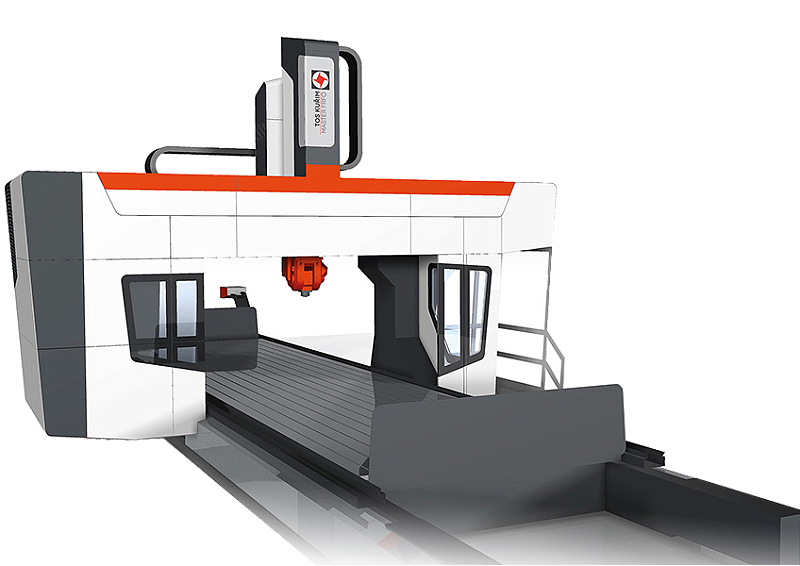

FRF

FRU

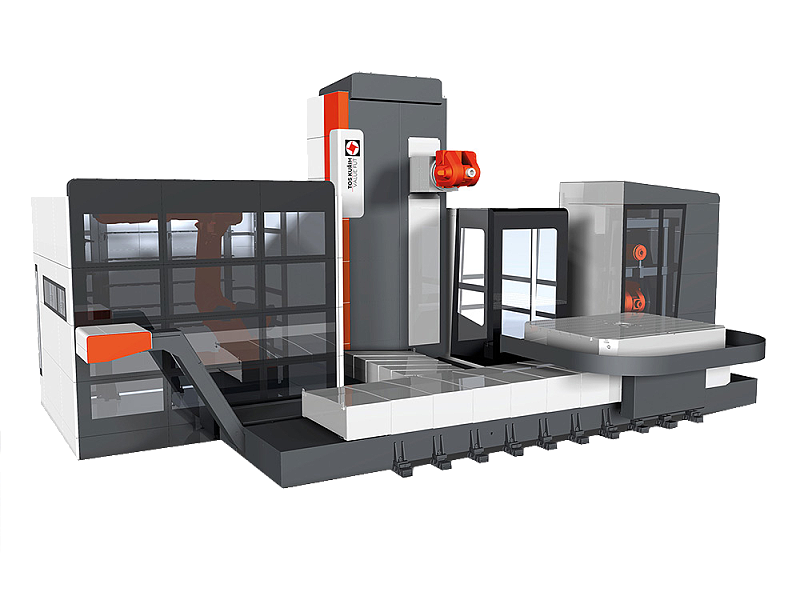

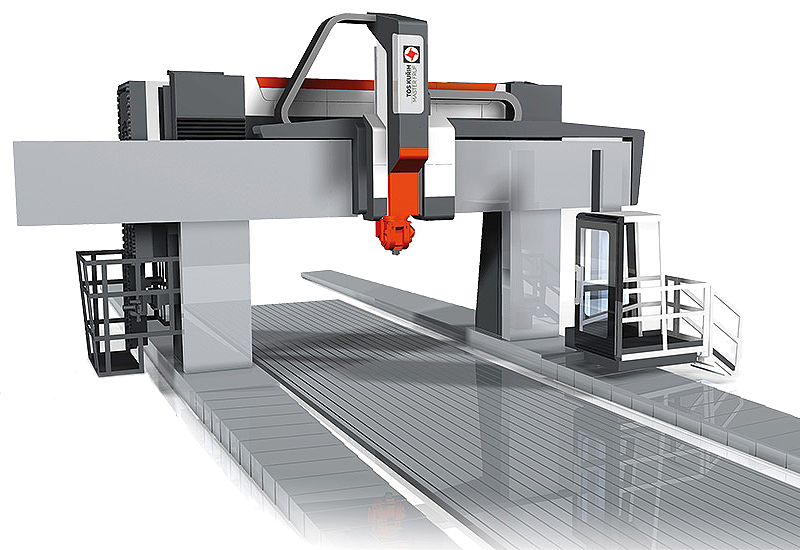

MMC 1500

HWT E-422 CNC

FTU / FTV / FTH (CNC)

FTU / FTV / FTH

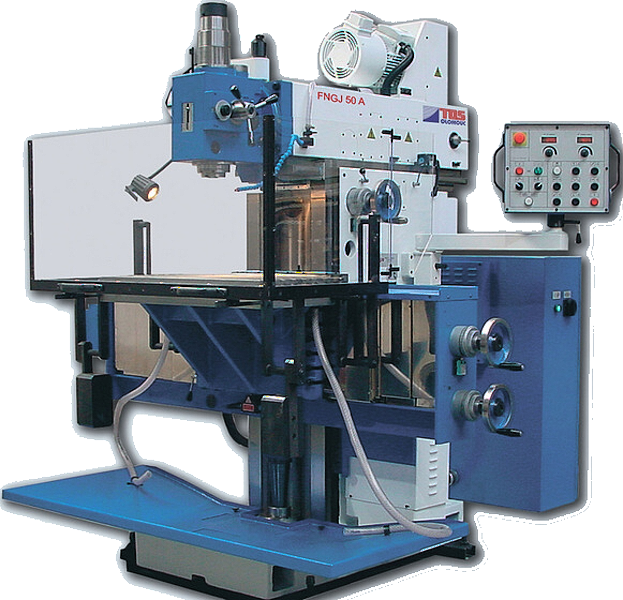

FNGJ 50

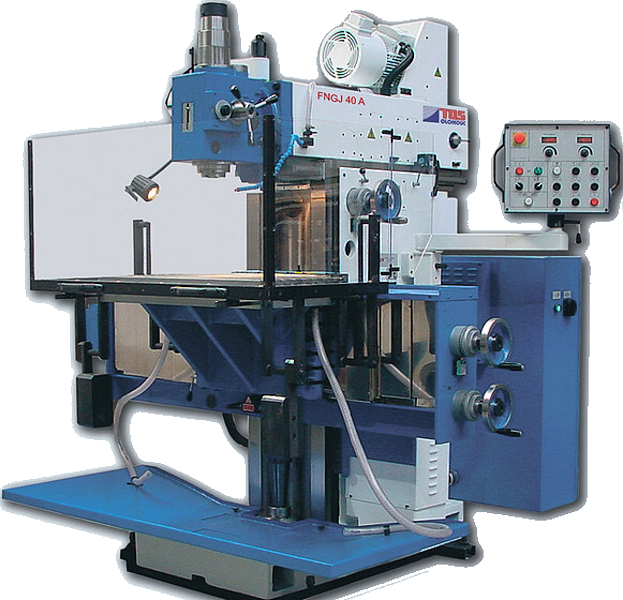

FNGJ 40 A

FNG 50 CNC A