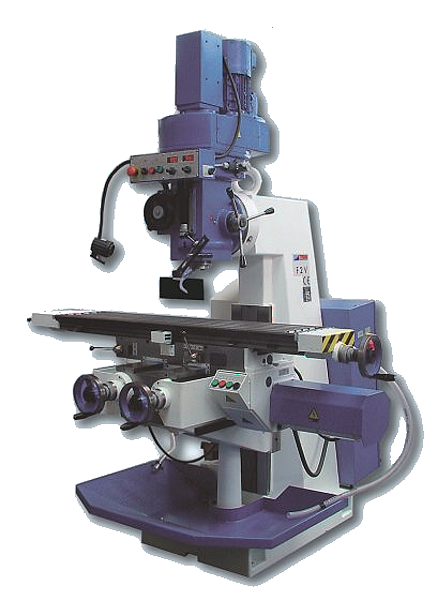

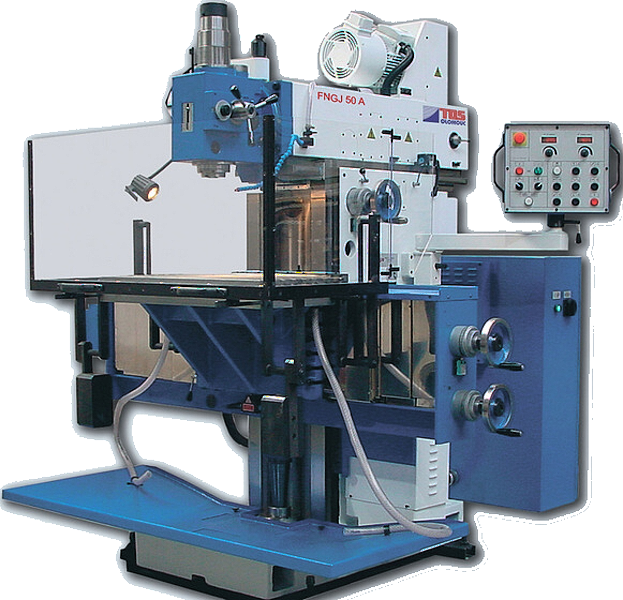

FNGJ 50

Tool-room milling machine FNFJ 50 A

FNGJ 50 A – is designed to cover a wide range of milling, drilling, boring and thread cutting operations on workpieces of to 350 kg weight. This machine is especially suitable for single pieces production at tool-making workshops. The machine is equipped with horizontal spindle which is fitted in the ram-type spindle head and also with vertical milling head, swing away arm for this vertical milling head and with fixed angle table. The machine is delivere with hand shift-out of the spindle quill. Tilting of spindle is possible in the range ± 90°. The perfect clamping of tools is realized by pneu-hydraulic clamping in both vertical an horizontal spindle. The stepless spindle speeds are divided into 2 steps with max. 4000 r.p.m. and together with stepless working feeds the machine enables economical machining of varios materials.

Optimal lubrication of guideways is solved by means of lubricaation pump with dosing device. Tools cooling equipment, working light and safety guard of working space are delivered as standard accessories.

Using of the optional equipment from our variety entlarges technological possibilities of the machine.

Advantages:

- Stepless spindle speeds by means of frequency convertor in 2 steps

- Spindle in the quill with fine and large shift-out

- Stepless feeds in 3 axes by means of a frequency convertor

- Pneumatic-hydraulic tool clamping in the horizontal and vertical spindle (Special execution)

- Hardened guideways

- Simple and comfortable operation, compact layout

- Central lubrication by means of dosing devices

- Wide range of technologic possibilities

- High rigidity, accuracy and reliability of the machine

- Easy maintenance

- Modern design and perfect surface finish with oil-resistant painting

Basic machine features

- trapezoidal feed screws are heat treated and found

- feeds in all axes as well as spindle revolutions – stepless

- quick and easy control

- fixed angle table 900 x 500 mm

- frequency convertor in the spindle drive

- shift out of the quill

- central lubrication with dosing devices

- tool cooling equipment

- lighting of the working space

- safety guard of the working table

- chip tray

FGV32

FGU32

F2V/R

FU

FUT

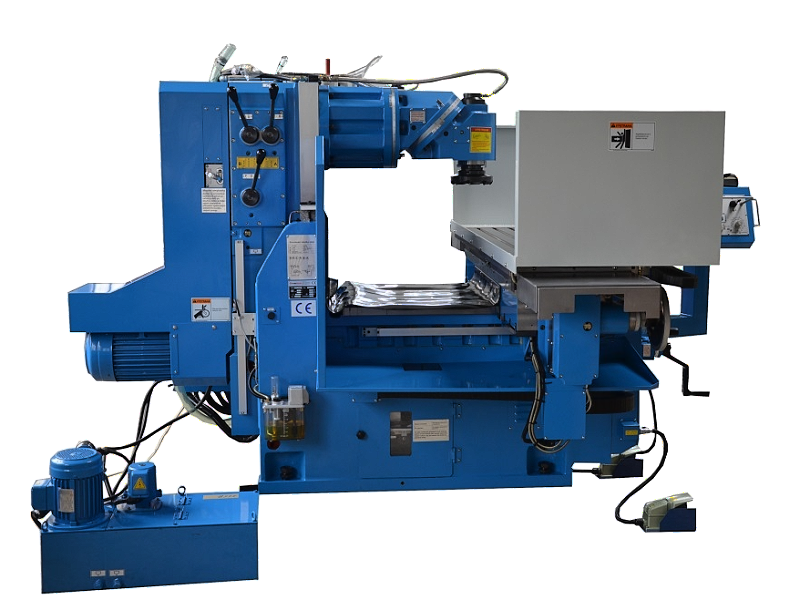

FRP

FRF

FRU

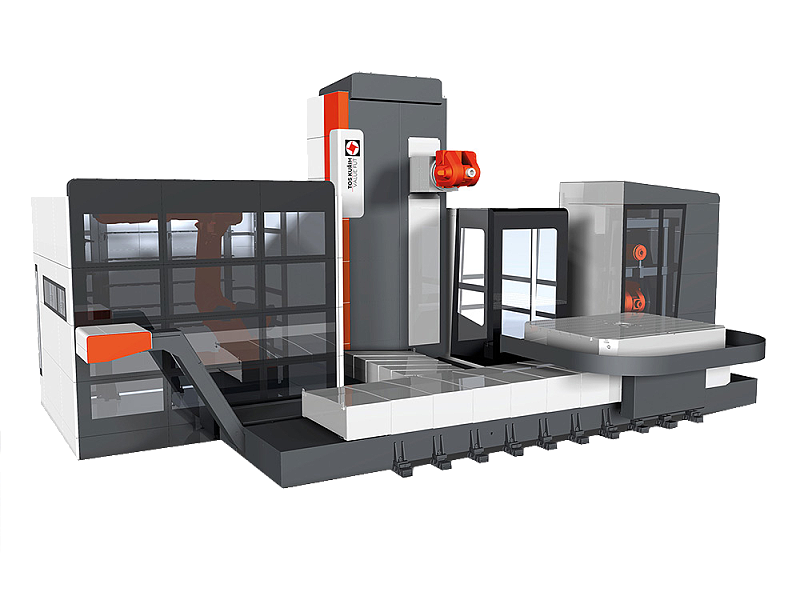

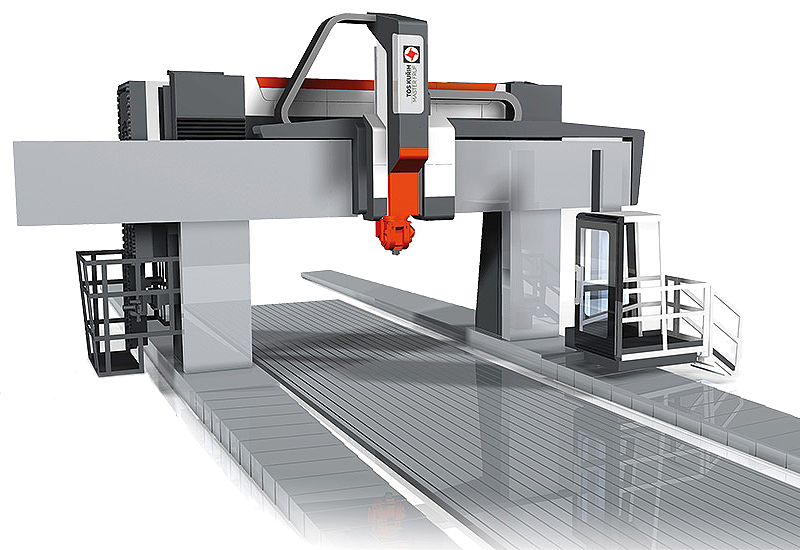

MMC 1500

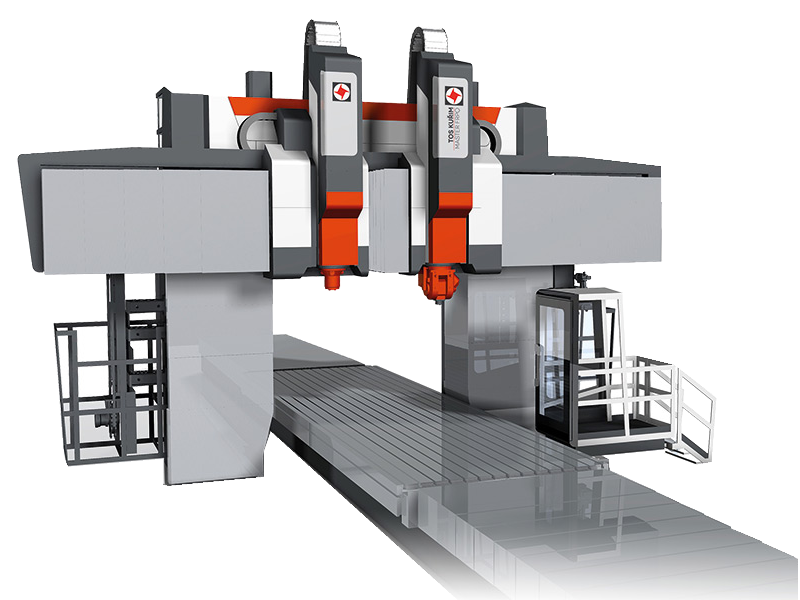

HWT E-422 CNC

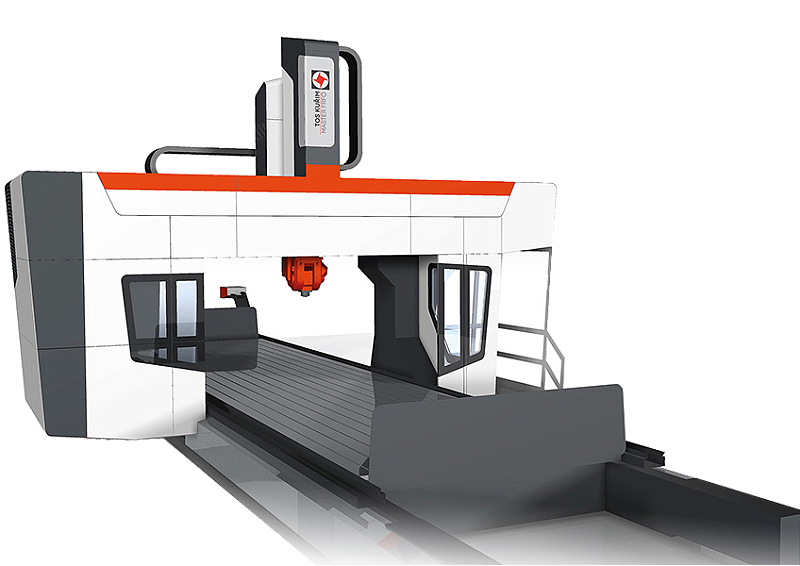

FTU / FTV / FTH (CNC)

FTU / FTV / FTH

FNGJ 50

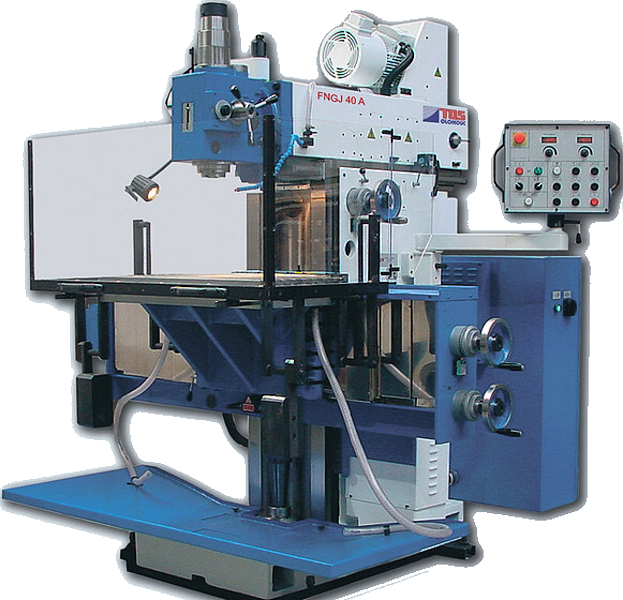

FNGJ 40 A

FNG 50 CNC A