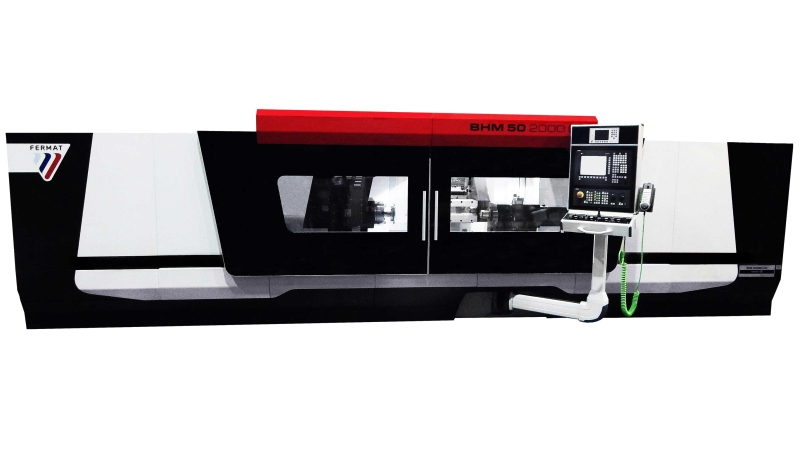

BHM CNC

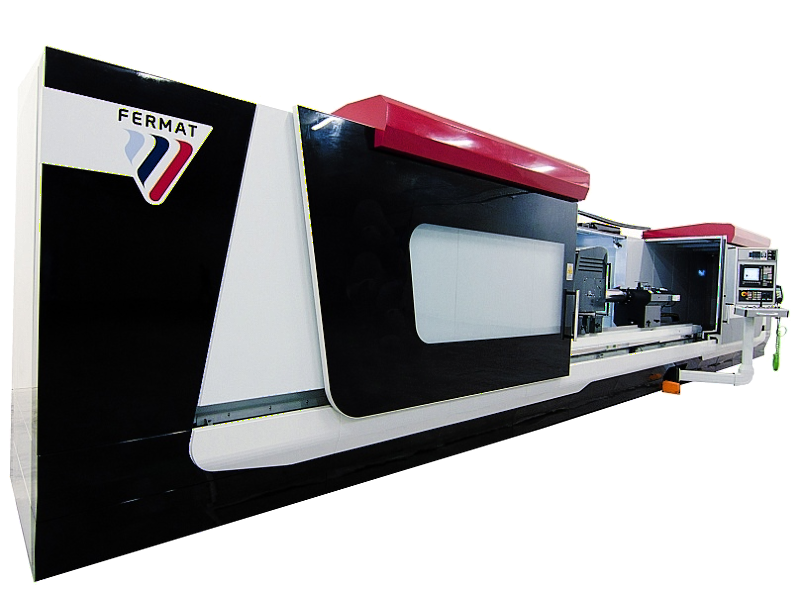

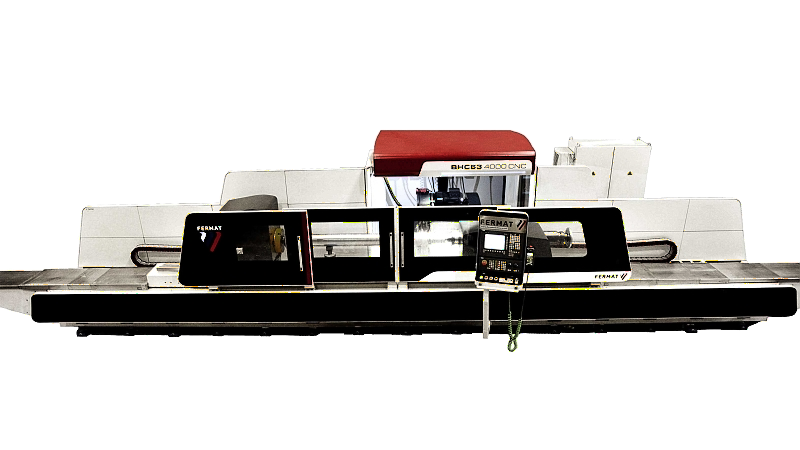

Universal grinding machine BHM

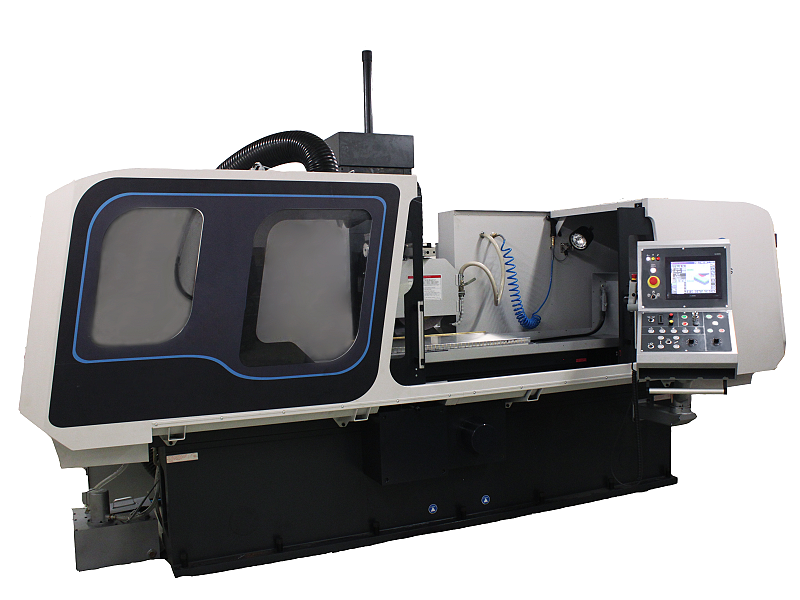

BHM universal grinding machine is designed for grinding of external or internal workpieces clamped between centers or by flying-mode into the chuck (special equipment) with the drive headstock and the possibility of sequential longitudinal grinding, plunge-cut grinding with a moving table, as well as plunge-cut grinding with a fixed or oscillating table. The cylindrical or conical surfaces may be ground in the centers. So called sweep cones may be ground by interpolation between axis X and Z. Grinding wheel head is mutually rotational. It enables vertical plunge-cut grinding using work head swivel. This method may be particularly used for grinding steep cones and simultaneous grinding of cylindrical and face surfaces of workpieces.

BHM universal grinding machine can be of use particularly in the piece and small-lot production for grinding workpieces weighing up to 850 kg or 1000 kg with steady rests. Automatic working cycle, adjustment possibilities and control gauge device predestine this grinder for economical grinding even in the serial production. On one hand, the grinder satisfies growing demands for higher performance and on the other hand it keeps its universality and simplicity regarding operation of the machine. It grinds in precision accuracy IT 4. It is equipped with modern design elements such as grinding wheel head in-feed by a ball screw with a rolling guidance of a grinding wheel head. Longitudinal machine feed is also controlled by a ball screw. The machine is fitted with control system SINUMERIK 828 D sl and servomotors SINAMCS S 120 on axes X and Z. Interpolation of mutually perpendicular axes Z (longitudinal table feed) and X (grinding wheel head cross feed-in) enables the use of a wide range of grinding methods and contour dressing of wheels for both internal and external grinding. Grinding of face surfaces can be performed by the side of the grinding wheel. Control elements of the machine are effectively placed at the operator´s seat. They are easily accessible and so enable good controllability of the machine. Special equipment essentially broadens working possibilities of the machine and favorably influences grinding quality.

Machine design

- highly stable bed with reinforcement,

- excellent friction characteristics of Teflon,

- according to the CE standard,

- CNC control systems (SIEMENS, B&R),

- digital AC servomotors,

- controlled axis X (grinding wheelhead in-feed), Z (table feed),

- hand-wheel for axis X and Z setting,

- equipped with fully covering and manually controlled doors,

- telescopic covers,

- cooling with belt and magnetic filter,

- robust and rigid duo table.

The machines are additionally equipped and designed according to specific needs of the customer and taking into account the materials to be ground or the selected Machining technology.