Request

RET10P

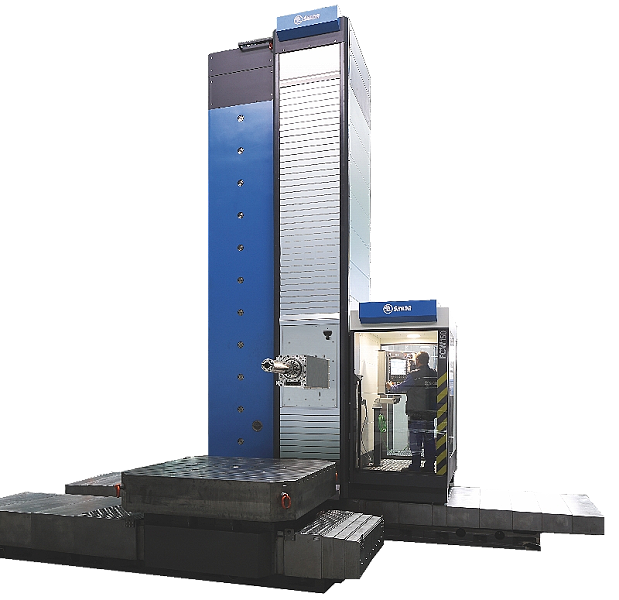

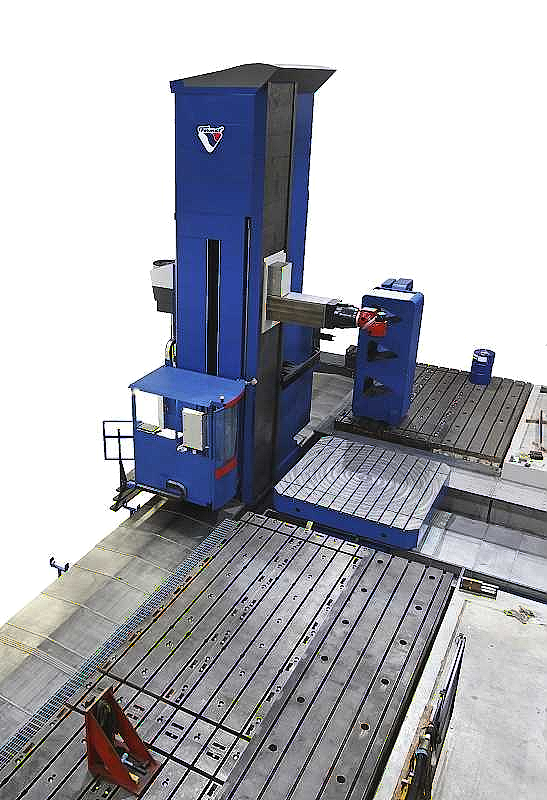

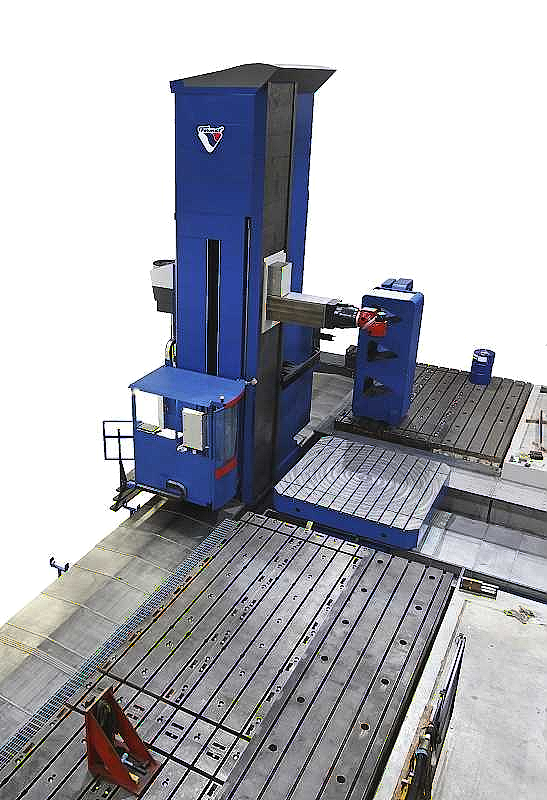

The RET10P is a contouring floor type of a horizontal boring machine. It fully meets the requirements on high production productivity, with maximum consideration of safety and operation convenience, as well as thoughtfulness towards the environment.

Floor type Horizontal boring machine RET10P

RET10P – is a contouring floor type of a horizontal boring machine. It fully meets the requirements on high production productivity, with maximum consideration of safety and operation convenience, as well as thoughtfulness towards the environment. Machine is suitable for roughing as well as for finishing. Thanks to its unit principle, this machine excels in a maximum variability of design for various technological applications. According to your specific needs, you can choose between feeds in the V axis (ram) or W axis (spindle) or in both of them.

Features

- contouring floor type of horizontal boring machine

- transversal travelling column

- 3/4 linear axes

- sliding ram / workspindle or a combination of them

- machine suitable for machining of large workpieces

- suitable for roughing as well as for finishing

- travel ranges, number of axes, and clamping surfaces and the level of coverage can be customized according to your specific needs

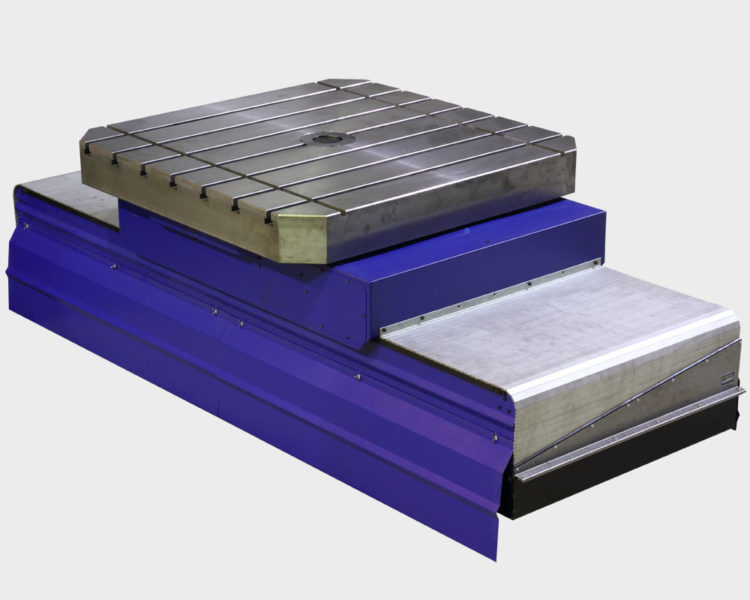

- workpiece is clamped to a clamping plate or a rotary table (it is not a part of the machine)

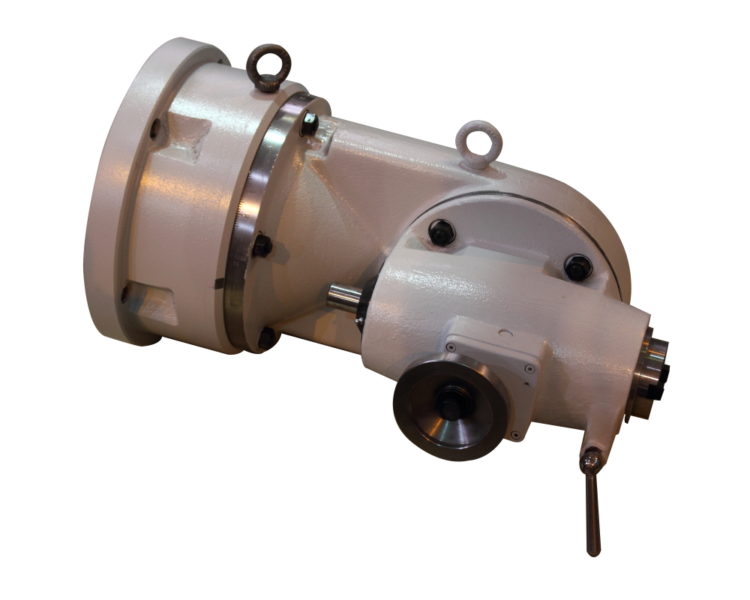

- according to your needs, option of fitting with a broad spectrum of accessories, such as automatic tool changing systems (ATC), various milling heads and milling head changing systems (AHC), a facing head, tool cooling kit (CHZ), cooling through spindle axis (CHOV), oil-mist cooling (CHM) or swarf conveyor

- “Industry 4.0” ready

In addition, milling heads, facing heads, ATCs and further accessories are available.

- transversal travelling column

- 3/4 linear axes

- sliding ram / workspindle or a combination of them

- machine suitable for machining of large workpieces

- travel ranges, number of axes, and clamping surfaces and the level of coverage can be customized according to your specific needs

- workpiece is clamped to a clamping plate or a rotary table (it is not a part of the machine)

- according to your needs, option of fitting with a broad spectrum of accessories, such as automatic tool changing systems (ATC), various

milling heads and milling head changing systems (AHC), a facing head, tool cooling kit (CHZ), cooling through spindle axis (CHOV), oil-mist cooling (CHM) or swarf conveyor

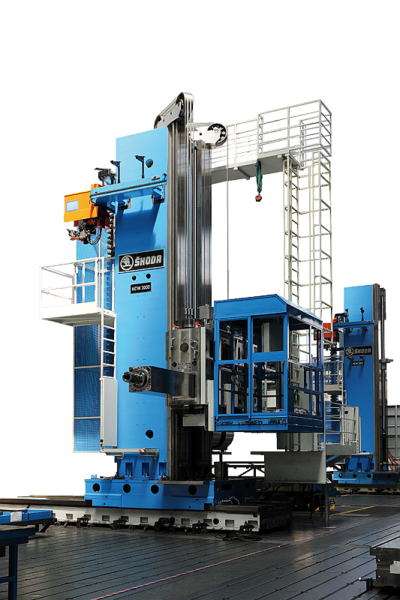

HCW1, HCW2, HCW3, HCW4

HCW 2000, HCW 3000, HCW 4000

FCW 140, FCW 150, FCW 160

WRF 160 CNC / WRF 160 HEAVY

WRF150 CNC

WRF 130 CNC

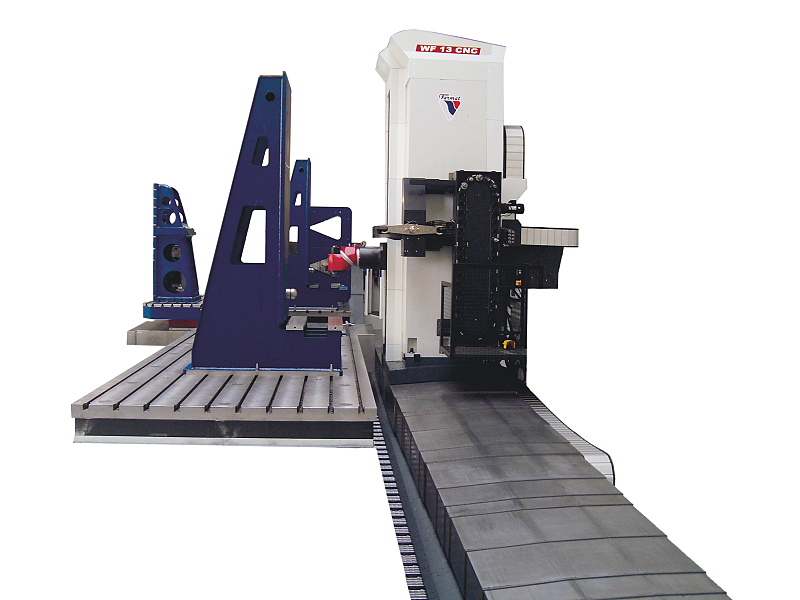

WF 13 CNC

WRD 13 (Q)

WRD 130 / WRD 150 (Q)

WRD 170 (Q)

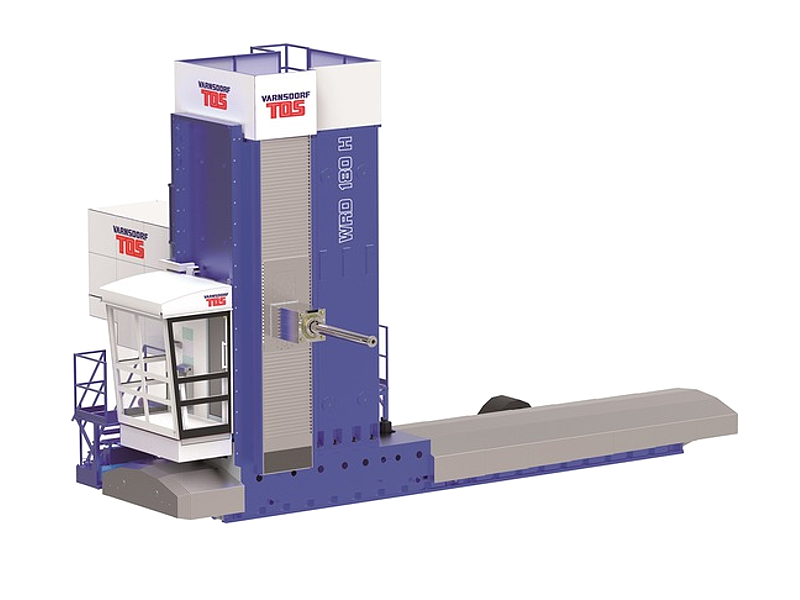

WRD 180 H