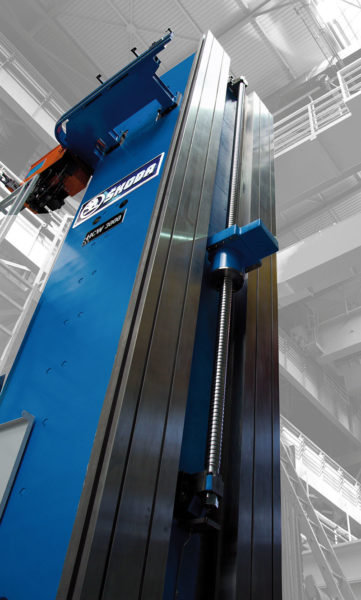

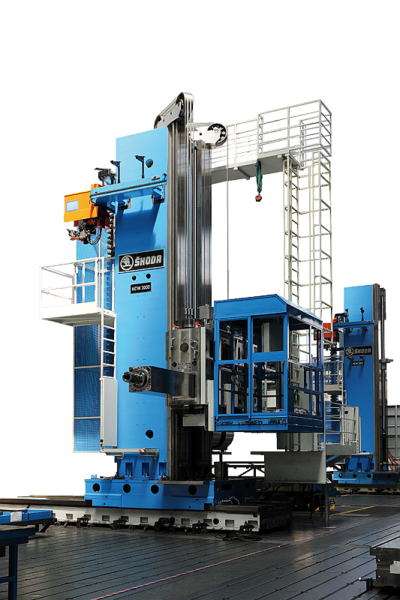

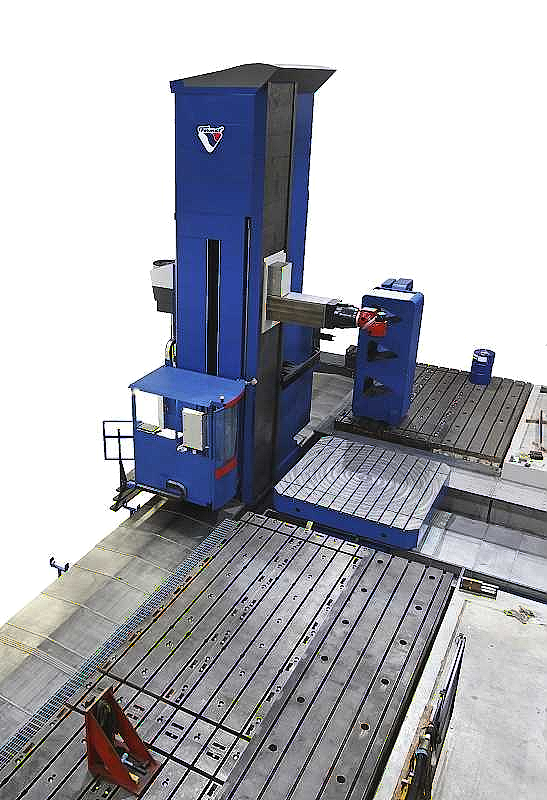

HCW 2000, HCW 3000, HCW 4000

HCW 2000, HCW 3000, HCW 4000 - horizontal boring machines, fully hydrostatic high-speed machine achieving micron accuracy even when the quill is fully extended from the headstock.

Request

Horizontal milling and boring machine HCW 2000 – 4000

HCW 2000, HCW 3000, HCW 4000 – horizontal milling and boring machines, fully hydrostatic high-speed machine achieving micron accuracy even when the quill is fully extended from the headstock. The stability of the boring machine is ensured by a rigid frame cast from gray cast iron. The pull-out quill is hydrostatically guided with automatic compensation of the drop during extension. The spindle is mounted in special angular contact ball bearings. The spindle is mounted in special angular contact ball bearings and lubricated with a minimum amount of oil. Shifting is provided by hydraulics via gear couplings. A large number of special and additional accessories can be supplied with the machine.

Description of main groups of machine:

Bed

- Grey cast iron structure – GG 30 (DIN)

- Two main guide ways and two side guide ways

- Upper (main) and side guide ways hydrostatic. Side guiding on inner surfaces of the bed.

- Grounded or fine milled surface of guide ways

- Hardness of guide ways for hydrostatic 200 +/- 20 HB

- HEIDENHAIN linear scale for X-axis located on the bed

- Hardened teeth rack for X – axis feed bolted to the bed section

- Limit switches for X – axis

- Telescopic protective steel-sheet covers over the whole width of the bed with slope towards chip conveyor

Column Saddle

- Grey cast iron structure – GG 25 (DIN)

- Moving along the bed (X axis)

- Low-friction special plastic material attached to the hydrostatic guide ways of saddle

- Hydrostatic oil is supplied to guide ways by high pressure coming through hydrostatic pockets; hydrostatic oil pressure is controlled by CNC system

- Thickness of hydrostatic oil film about 0,02 – 0,03 mm

- Backlash-free twin-pinion gearbox driven by two AC drive in Master-Slave loop for movement in X – axis

Column

- Grey cast iron structure – GG 30 (DIN)

- Firmly attached to column saddle by set of bolts

- Double-wall front side of casting

- Upper (main) and side guide ways hydrostatic. Side guiding on inner surfaces of the column.

- Rear guiding hydrostatic.

- Grounded or fine milled surface of guide ways

- Counterweight for ram’s dropping compensation inside the column

- HEIDENHAIN linear scale for Y-axis located on the column

- Ball screw with rotating nut for movement in Y – axis (K100x20)

- Limit switches for Y – axis

- Telescopic protective steel-sheet covers over and below the headstock

- Ladder for entrance to platform of headstock or column’s top

HCW1, HCW2, HCW3, HCW4

HCW 2000, HCW 3000, HCW 4000

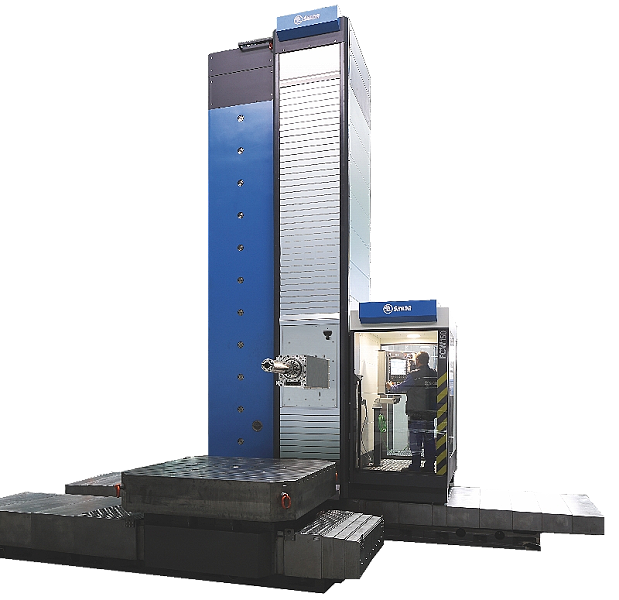

FCW 140, FCW 150, FCW 160

WRF 160 CNC / WRF 160 HEAVY

WRF150 CNC

WRF 130 CNC

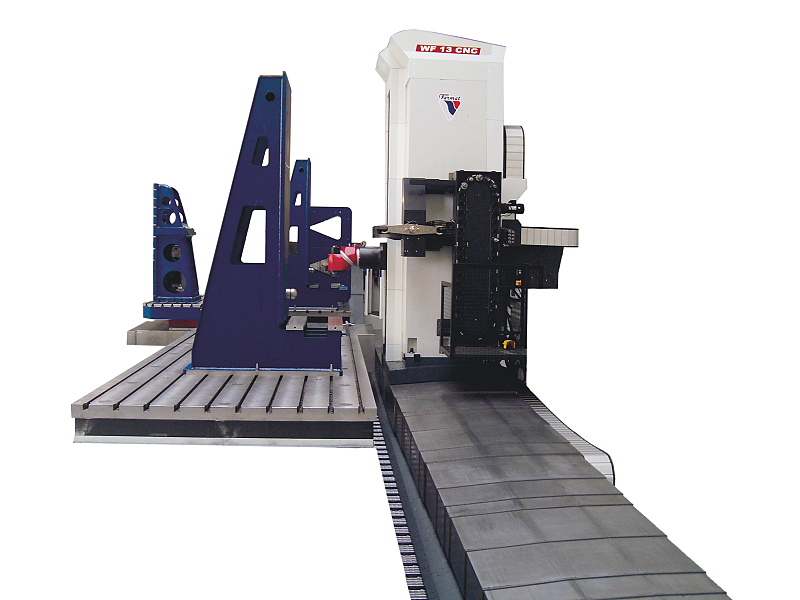

WF 13 CNC

WRD 13 (Q)

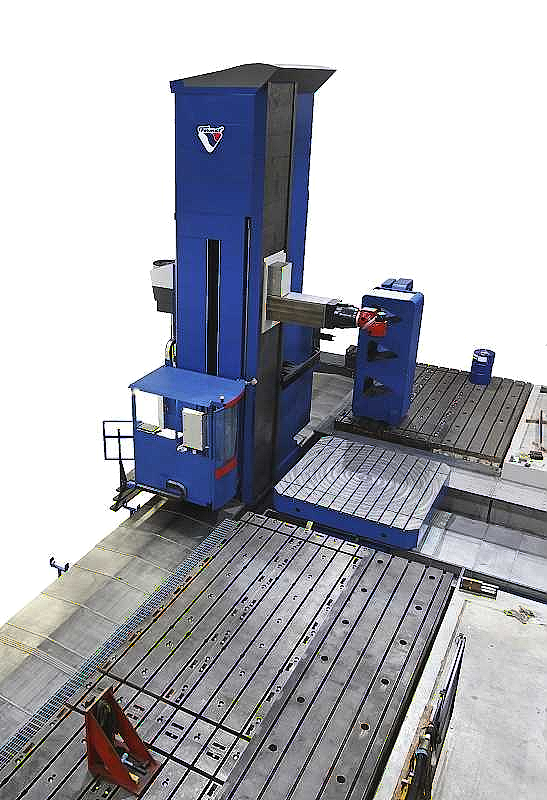

WRD 130 / WRD 150 (Q)

WRD 170 (Q)

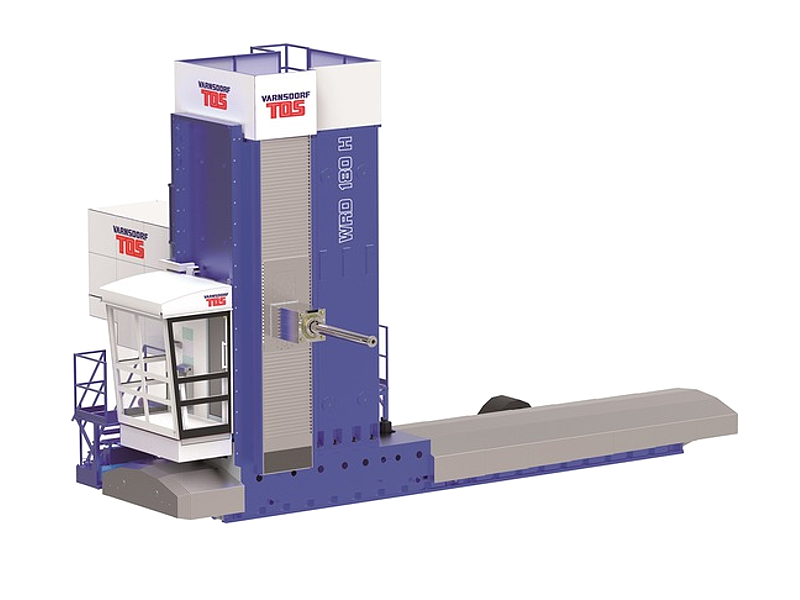

WRD 180 H