MORI-SAY 657AC, 667AC

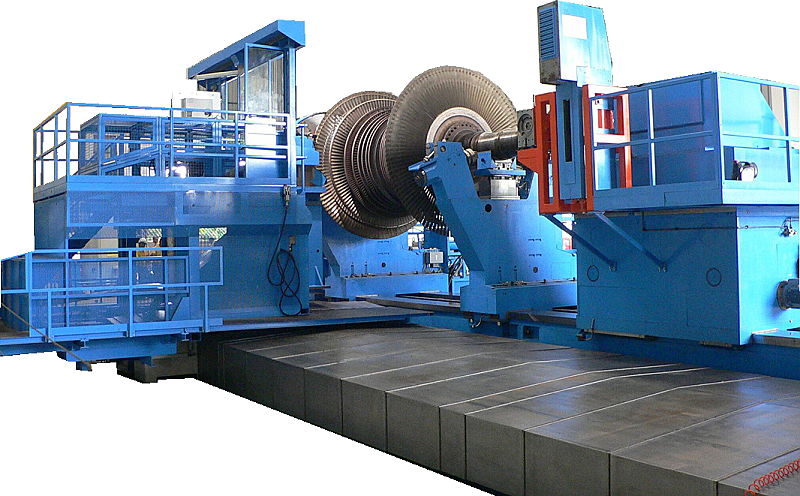

Multi-spindle automatic lathes MORI-SAY 657 / 667 AC

Numerically controlled automatic lathe Mori-Say 657 / 667 AC is the new machine conceptually congruent with the series of the TAJMAC–ZPS multi-spindle automatic lathes. It is intended for the mass and series production of the precise components from the bar stock.

The machine is manufactured as fully mechanical with regulation sliding and spindle engine operand by programmable automat. The machine can produce also two various parts and work as twice three-spindle.

The machines MORI-SAY 657 AC and MORI-SAY 657 SAC are intended for production of machine parts from bar stock with the maximum length of 4,000 mm with the diameters to 57mm and hexagons to 50mm. The ends of bars must be chamfered at least at 1.5 x 65 degrees (vertex angle – 50 degrees). Admissible tolerance of both circular and non-circular cross section of a bar clamped in the collet bush is within IT 11 tolerance. The bars must be straightened of 1 mm on length of 1,000 mm.

Surface quality:

The bar surface should smooth, glossy or matt, free of laps, non-metallic inclusions and scales,mechanical impurities and signs of corrosion. Only isolated defects – grooves, impressed hollows, marks from blasting and straightening and cleaned spots are acceptable.

After additional installation of the optional equipment, the machine can produce also two different simple parts – it operates as a double three-spindle machine.

The machines MORI-SAY 657 AC are manufactured in basic versions full mechanical with variable speed of feed and spindles motors control by programmable device with various number of numeric option and will adapt to various types of collet´s.

STANDARD VERSION

- Spindle drum locking by a triad of rims with spur gearing

- SIMODRIVE SIEMENS variable speed motors

- PLC – SIEMENS SIMATIC programmable logic controller, S7-300 model

- 6 cross slides and 6 frontal slides

- 4 independent compound slides in the 1st, 2nd, 4th and 5th stations

- Feeding, clamping and bar stop in the 6th station

- 4 safety clutches preventing from the slides overloading

- Standard bar stock guide

MACHINE VERSIONS

S version (STOP version) with the possibility of the general stop of spindles

KL285

KL435

SE520 SL

SR1, SR2, SR3, SR4, SR5

MANURHIN K’MX 1032

MANURHIN K’MX 916 CLEVER

MANURHIN K´MX816 CLEVER

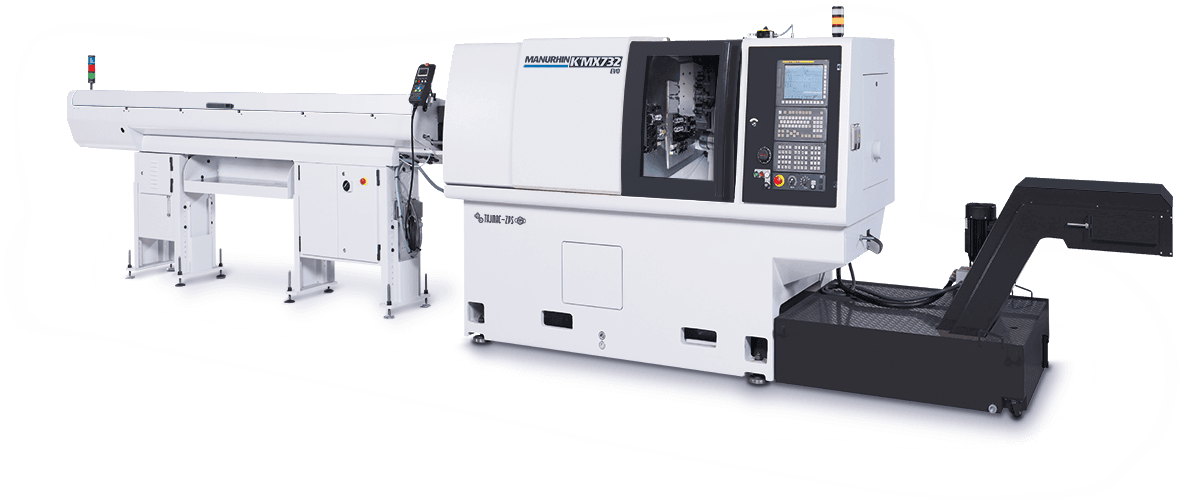

MANURHIN K´MX732EVO

MANURHIN K´MX632DUO

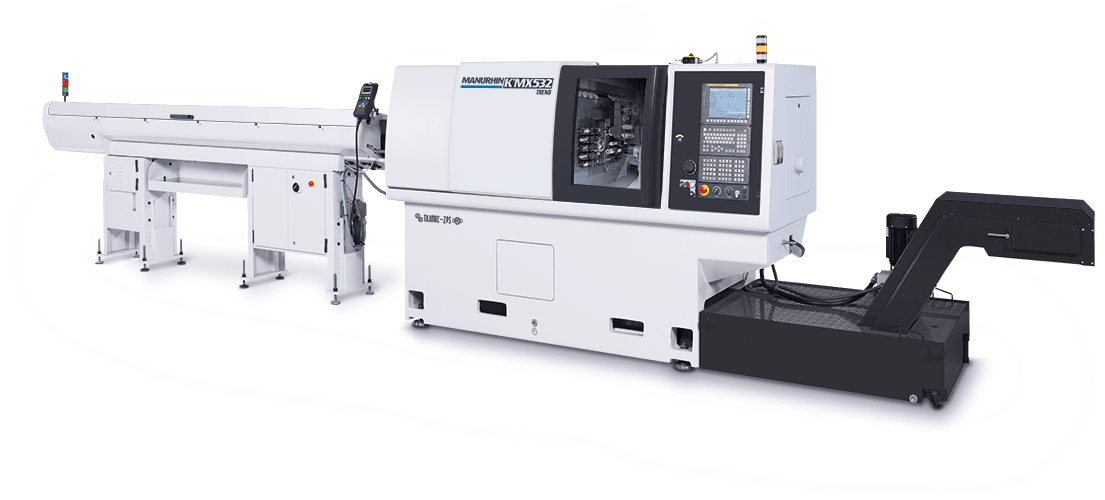

MANURHIN K´MX532 TREND

MANURHIN K´MX432

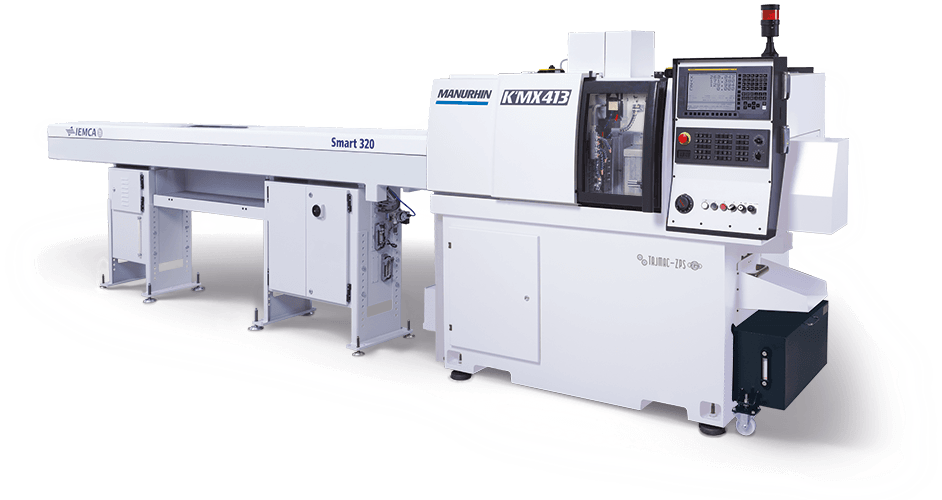

MANURHIN K´MX413

MORI-SAY TMZ867 CNC

MORI-SAY TMZ842 CNC

MORI-SAY TMZ642 CNC

MORI-SAY 832AC / 842AC

MORI-SAY 657AC, 667AC

MORI-SAY 632AC / 642AC

MORI-SAY 620AC

SPH 50 / D / DS

MASTURN

SUA 150 Numeric

SUA 125 Numeric

SUA 100 Numeric

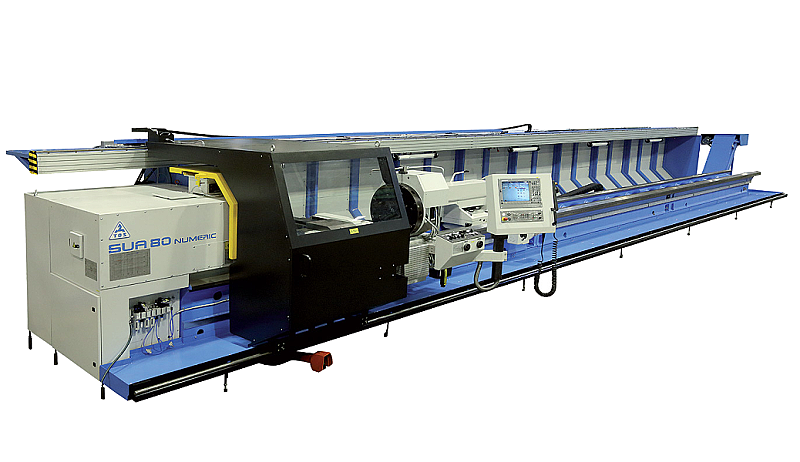

SUA 80 Numeric

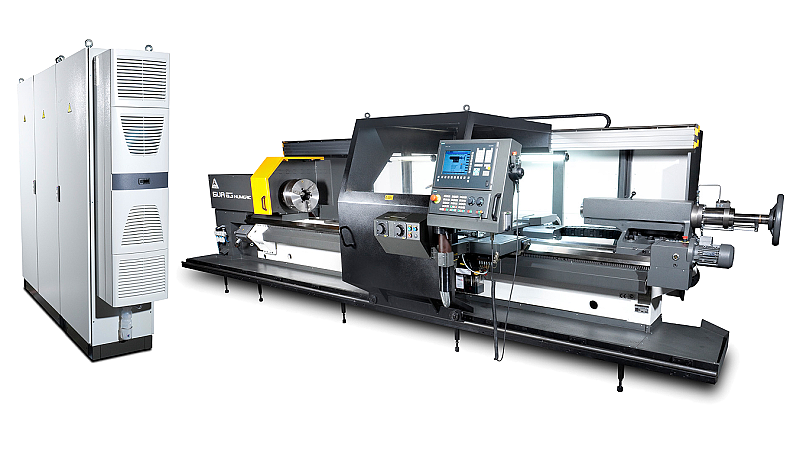

SUA63 Numeric

SBX 500 CNC

SBE300 CNC

SBL 700 CNC

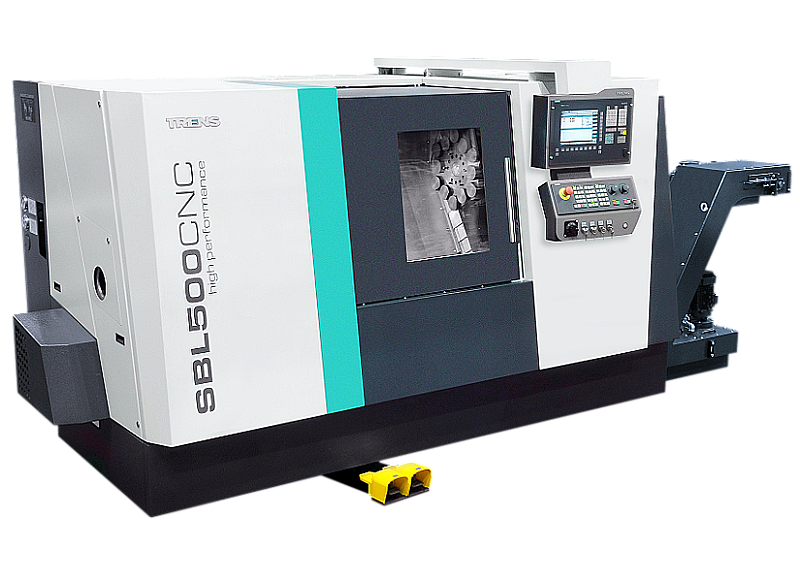

SBL 500 CNC

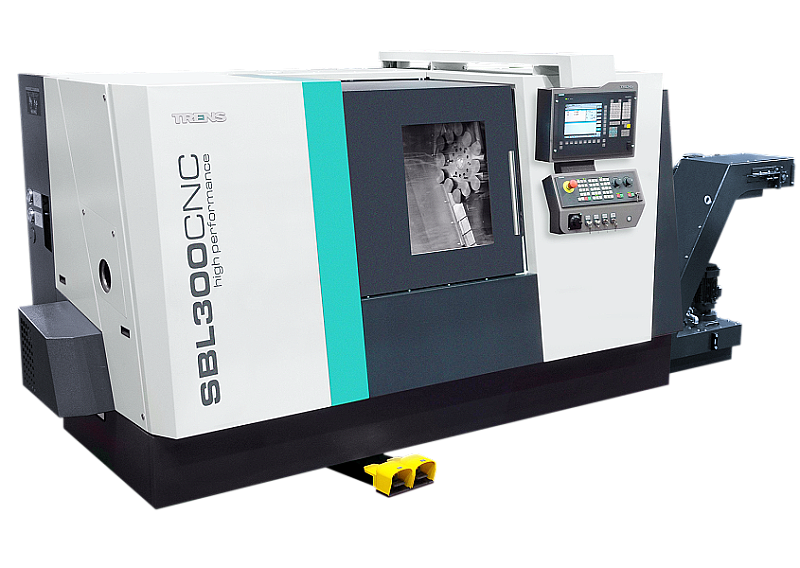

SBL 300 CNC

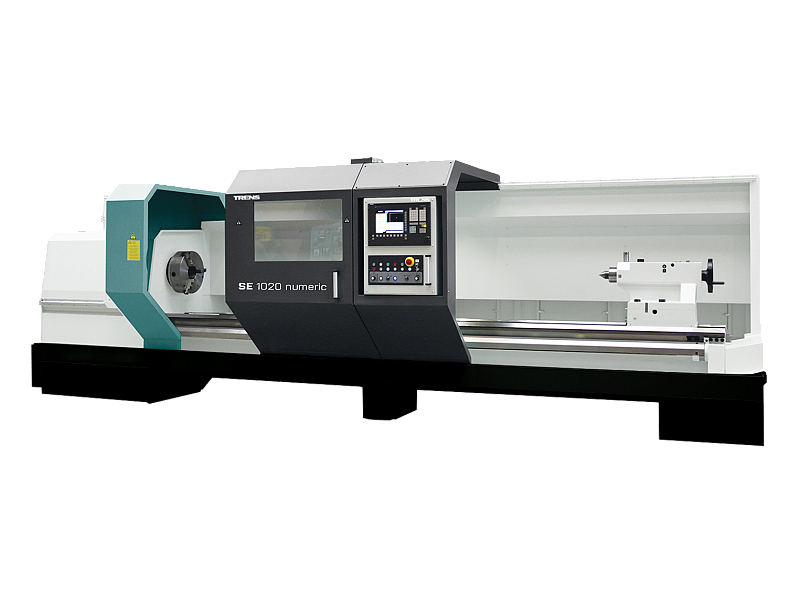

SE 1020 NUMERIC

SE 820 NUMERIC

SE 520 NUMERIC