Request

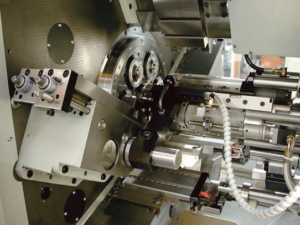

MORI-SAY 632AC / 642AC

Mori-Say 632AC / 642AC - Numerically controlled automatic lathe machine is comparable with other cam machines of the same size for the bar stock machining offered on the market.

The important improvements of the constructional character with the emphasis on amplification of the machine technological possibilities have been done without an interference with the conception of the MORI-SAY machines.

Numerically controlled automatic machine MORI-SAY 632AC / 642AC

Mori-Say 632AC / 642AC – Numerically controlled automatic lathe machine is comparable with other cam machines of the same size for the bar stock machining offered on the market.

The important improvements of the constructional character with the emphasis on amplification of the machine technological possibilities have been done without an interference with the conception of the MORI-SAY machines.

STANDARD EQUIPMENT

- Spindle drum locking by a triad of rims with spur gearing

- SIMODRIVE SIEMENS variable speed motors

- PLC – SIEMENS SIMATIC programmable logic controller, S7-300 model

- 6 cross slides and 6 frontal slides

- 4 independent compound slides in the 1st, 2nd, 4th and 5th stations Feeding, clamping and bar stop in the 6th station 4 safety clutches preventing from the slides overloading

- Standard bar stock guide

MACHINE VERSIONS

S version with the possibility of the general stop of spindles (632SAC and 642AC models)

OPTIONAL EQUIPMENT

- Independent drive of the central block

- Bar stock feeding attachment in the 1st station

- Device for the general stop of spindles – 632SAC and 642AC versions

- Hydraulic oriented stop of spindles – 632SAC and 642AC versions

- NC oriented stop of spindles – 632SAC and 642AC versions

- Bar stock feeding attachment in the 3rd station

- Pick-up spindle with hydraulically controlled collet clamping

- Brake of pick-up spindle

- NC drive of the pick-up spindle

- Mechanically controlled tool slide for the cut-off side machining in the 6th and 3rd stations

- NC tool slide for the cut-off side machining in the 6th station

- Tapping and thread chasing attachments

- High-speed drilling attachment

- Reaming attachment

- Attachment for a face milling at rotation and at spindle in standstill

- Push-broaching attachment

- NC drives of rotary tools

- Necking-down attachment

- Drilling heads on frontal slides – Two-spindle head, Three-spindle head, Four-spindle head

- Extra-axial drilling, fixed

- Extra-axial drilling, synchronous

- Cross drilling

- Drilling, milling and threading units

- Radial thread rolling

- Workpiece marking

- Thread milling and polygon machining at rotation

- Thread chasing

- NC compound slides for the 1st, 2nd, 4th and 5th stations

- Preparation for the automatic bar magazine

- Preparation for the oil mist exhaustion

- Selection of the equipment for the swarfs carrying out and coolant in an independent sedimentation tank

- High-pressure coolant and tool wash-out

- Setting-up for a part machining and the machine acceptance in the TAJMAC-ZPS plant

KL285

KL435

SE520 SL

SR1, SR2, SR3, SR4, SR5

MANURHIN K’MX 1032

MANURHIN K’MX 916 CLEVER

MANURHIN K´MX816 CLEVER

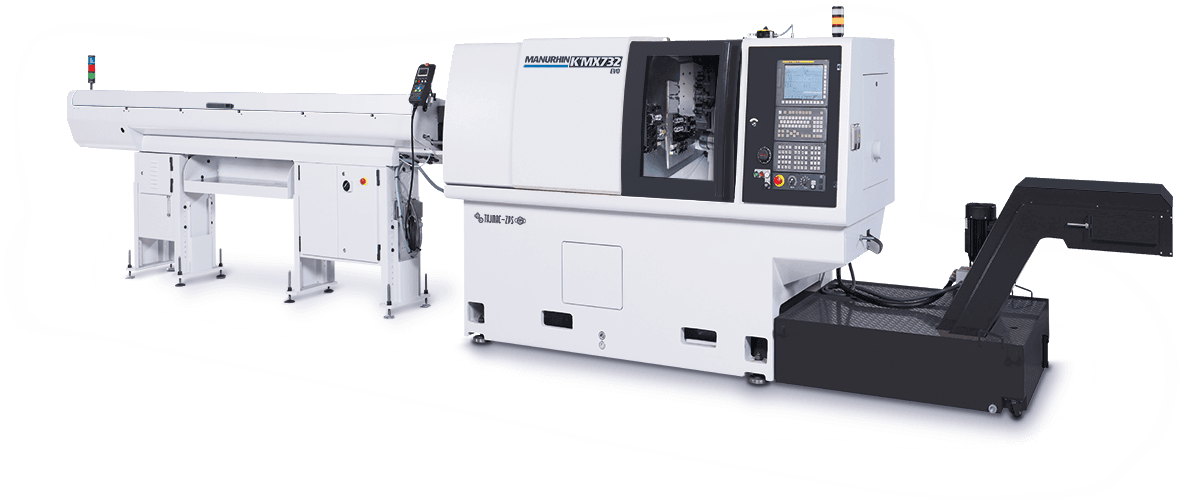

MANURHIN K´MX732EVO

MANURHIN K´MX632DUO

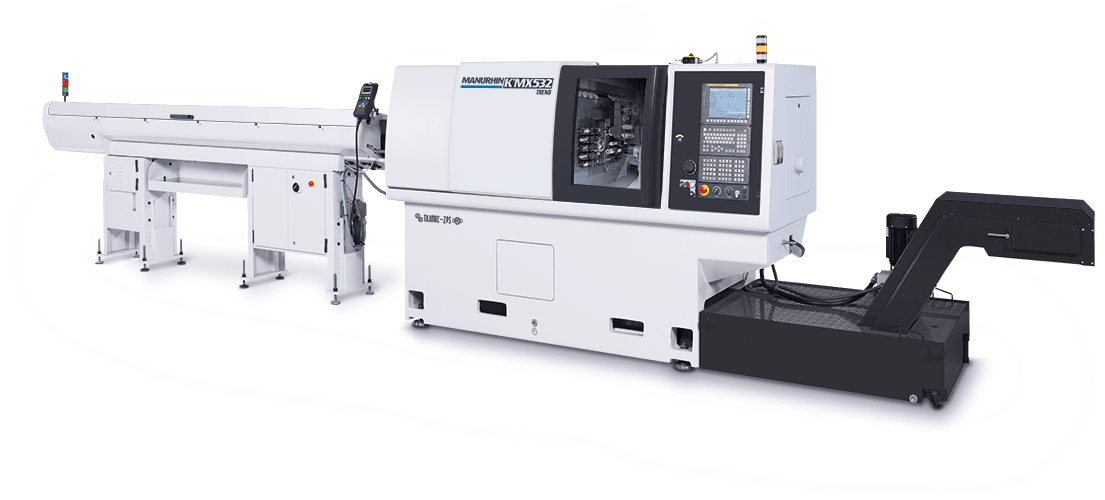

MANURHIN K´MX532 TREND

MANURHIN K´MX432

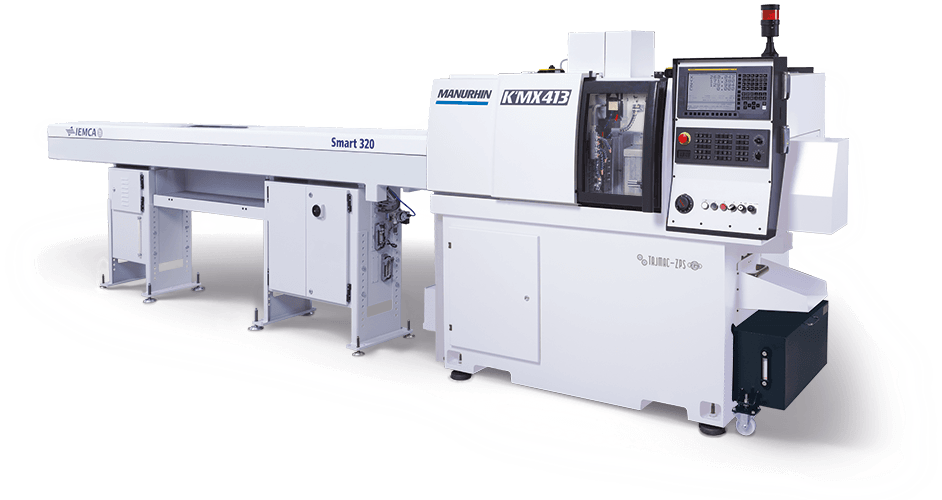

MANURHIN K´MX413

MORI-SAY TMZ867 CNC

MORI-SAY TMZ842 CNC

MORI-SAY TMZ642 CNC

MORI-SAY 832AC / 842AC

MORI-SAY 657AC, 667AC

MORI-SAY 632AC / 642AC

MORI-SAY 620AC

SPH 50 / D / DS

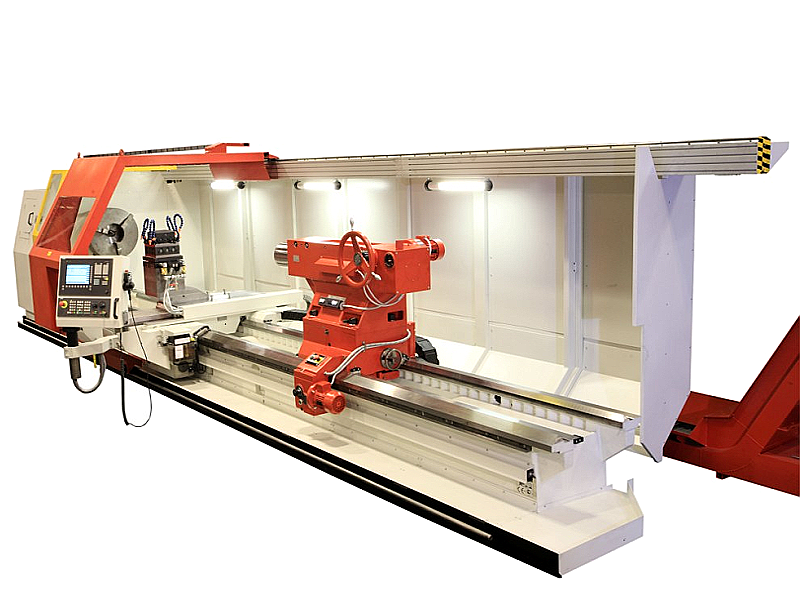

MASTURN

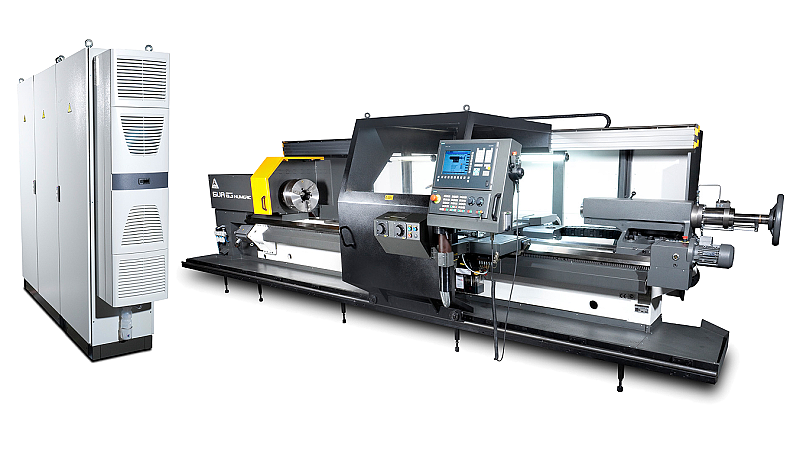

SUA 150 Numeric

SUA 125 Numeric

SUA 100 Numeric

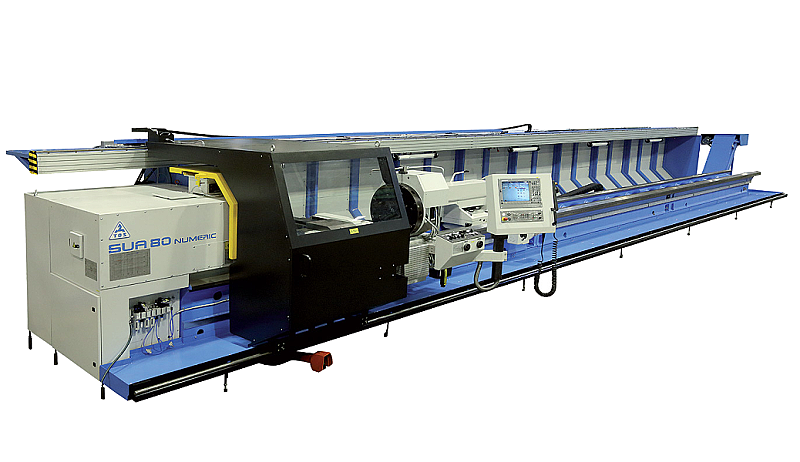

SUA 80 Numeric

SUA63 Numeric

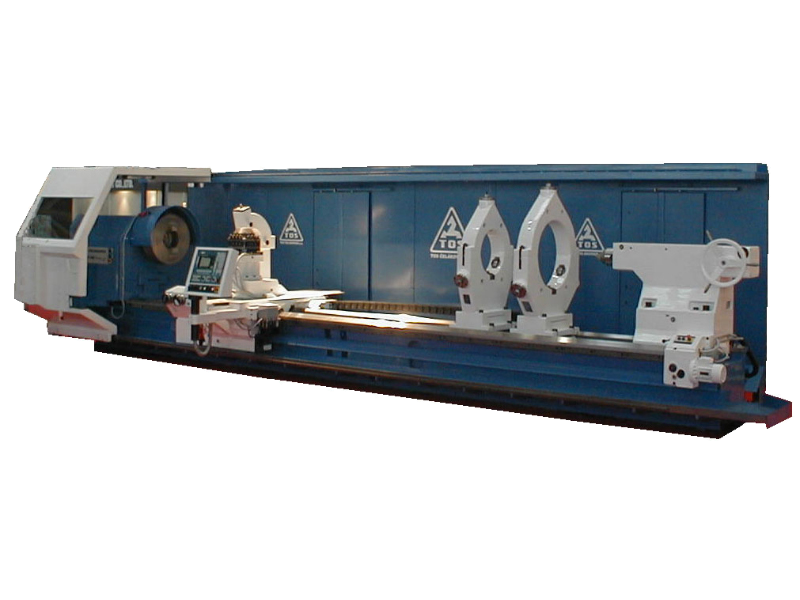

SBX 500 CNC

SBE300 CNC

SBL 700 CNC

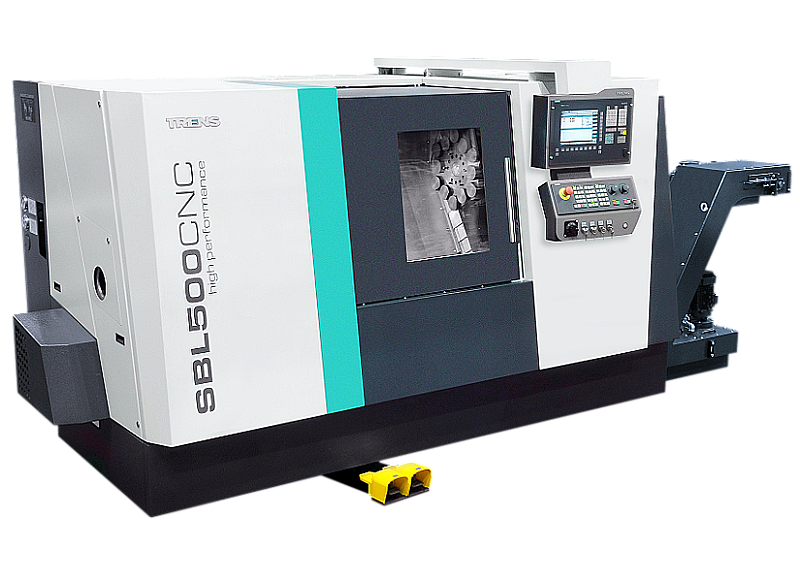

SBL 500 CNC

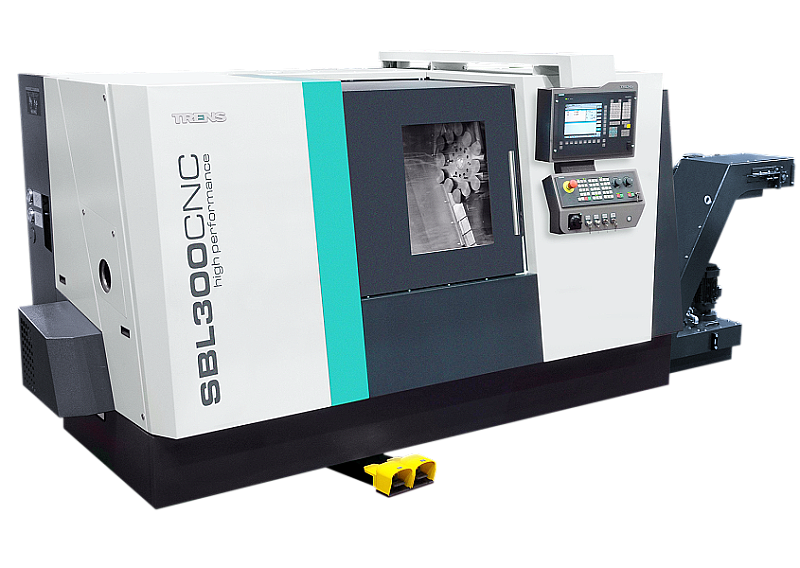

SBL 300 CNC

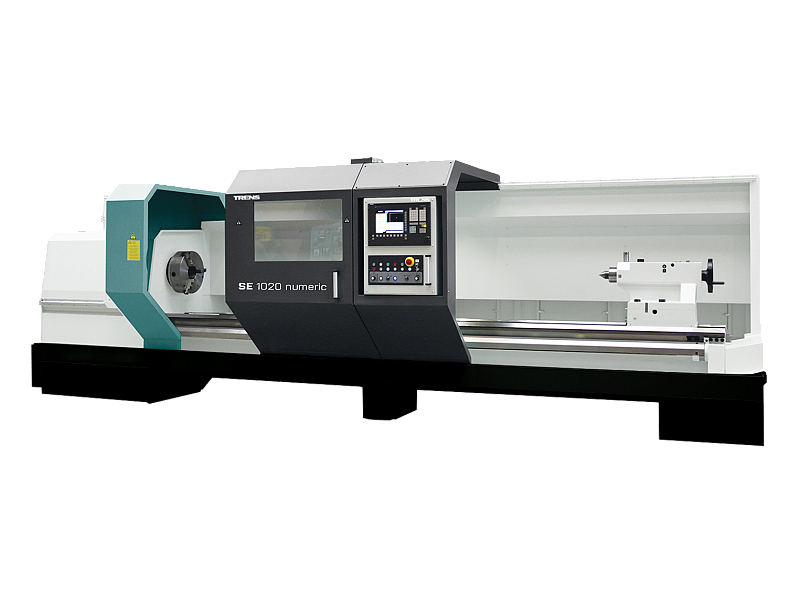

SE 1020 NUMERIC

SE 820 NUMERIC

SE 520 NUMERIC