Request

RET10X

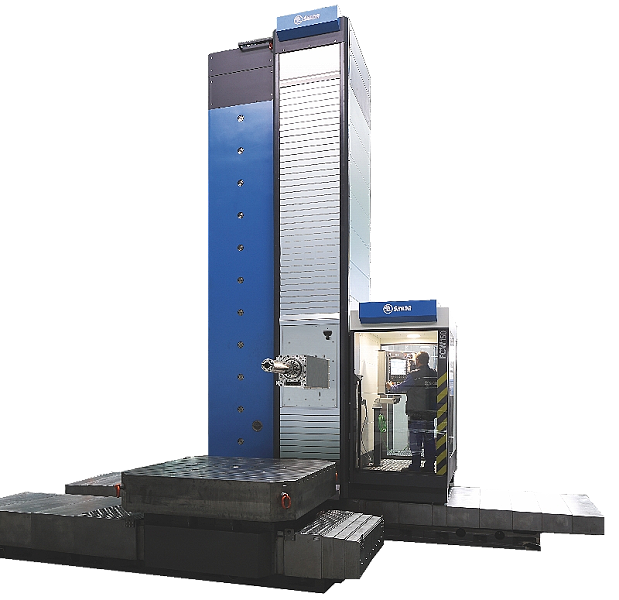

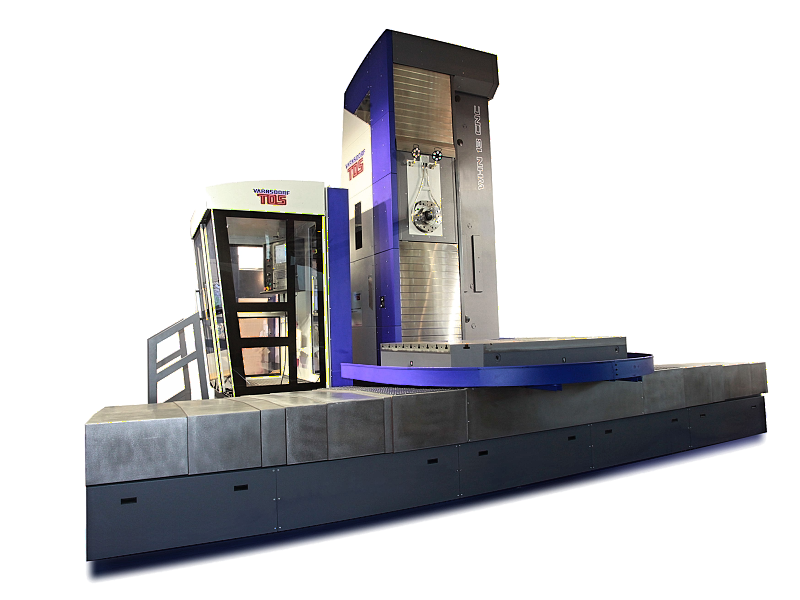

RET10X - T-TYPE HORIZONTAL BORING MILL - Thanks to its unit principle, this machine excels in a maximum variability of designfor various technological applications.

T-TYPE HORIZONTAL BORING MILL RET10X

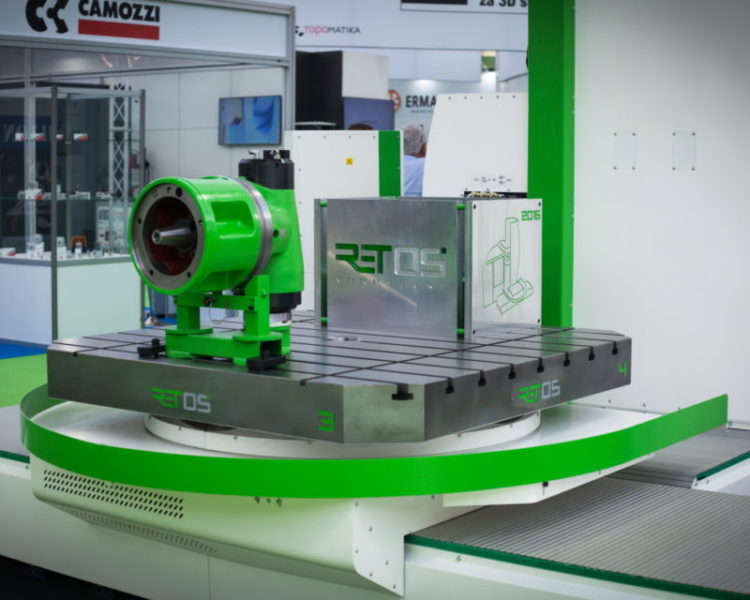

RET10X – T-TYPE HORIZONTAL BORING MILL – Thanks to its unit principle, this machine excels in a maximum variability of designfor various technological applications. According to your specific needs, you can choose between feeds in the V axis (ram) or W axis (spindle) or in both of them. Travel ranges in the main axes X, Y and Z, the size and number (1 or 2) of clamping plates with various functions (interpolation, positioning rotary tables, non-rotating tables) can be customized. In addition, milling heads, facing heads, ATCs and further accessories are available.

- Maximum variability – unit principle

- Choose travel range of basic axes Y, Z max. 2,000 mm, X max. 3,000 mm

- Rolling guideways for all axes

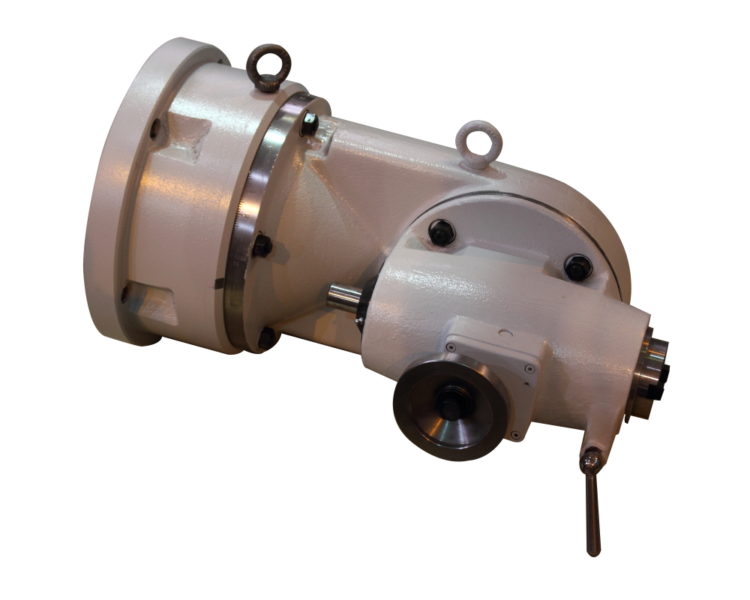

- Ram headstock

- Choose size and number of clamping plates / tables

- Wide range of technological accessories

FEATURES

- contouring T-type of horizontal boring machine

- 4 / 5 linear axes + rotary / non-rotary table

- sliding ram / workspindle or a combination of them

- machine designed for universal use in mechanical enigneering production

- suitable for roughing as well as for nishing

- travel ranges, number of axes, and clamping plates (1 or 2) and the level of coverage can be customized according to your specic needs

- according to your needs, option of tting with a broad spectrum of accessories, such as automatic tool changing systems (ATC), various milling heads and milling head changing systems (AHC), a facing head, tool cooling kit (CHZ), cooling through spindle axis (CHOV), oil-mist cooling (CHM) or swarf conveyor

CONTROLLING OF THE MACHINE

- all machine functions, except for clamping and unclamping, are controlled via the control panel, which consists of a keyboard, a switch panel and an LCD monitor

- the clamping and unclamping of tools is controlled by the key on the headstock

- the control panel is supplemented by a portable control panel (handwheel), which duplicates some of the basic control functions of the machine

- the control panel is swivellingly connected to the wall inside the operator housing

- the control system allows manual, semiautomatic and fully automatic modes

- the standard communication interface allows a connection with the Ethernet for easy administration and distribution of technological programs as well as diagnostics or servicing of the control system

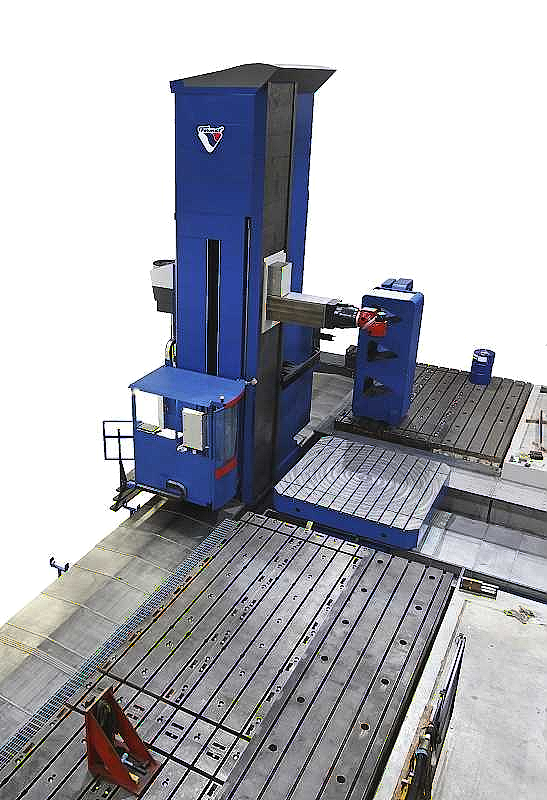

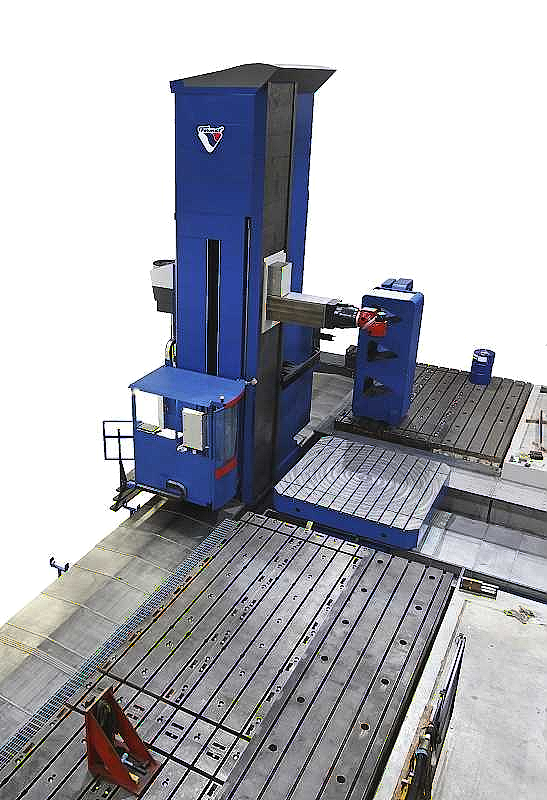

HCW1, HCW2, HCW3, HCW4

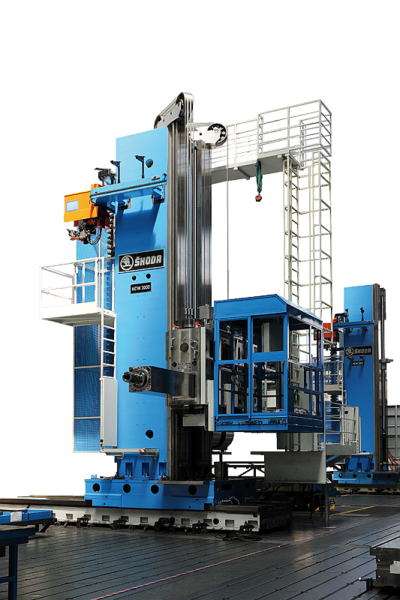

HCW 2000, HCW 3000, HCW 4000

FCW 140, FCW 150, FCW 160

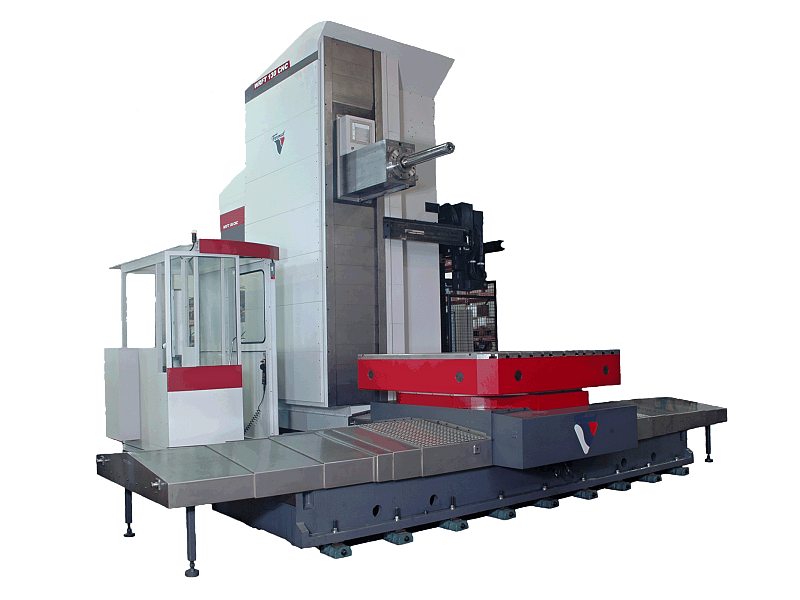

WRFT 130 CNC

WFT 15 CNC

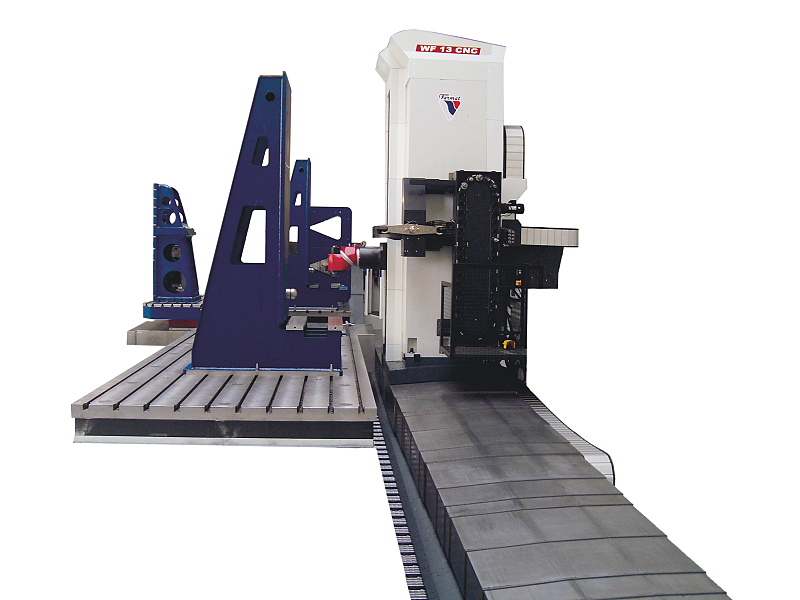

WFT 13 CNC

WFT 11 CNC

WRF 160 CNC / WRF 160 HEAVY

WRF150 CNC

WRF 130 CNC

WF 13 CNC

WFC 10 CNC

Maxima

WRD 13 (Q)

WRD 130 / WRD 150 (Q)

WRD 170 (Q)

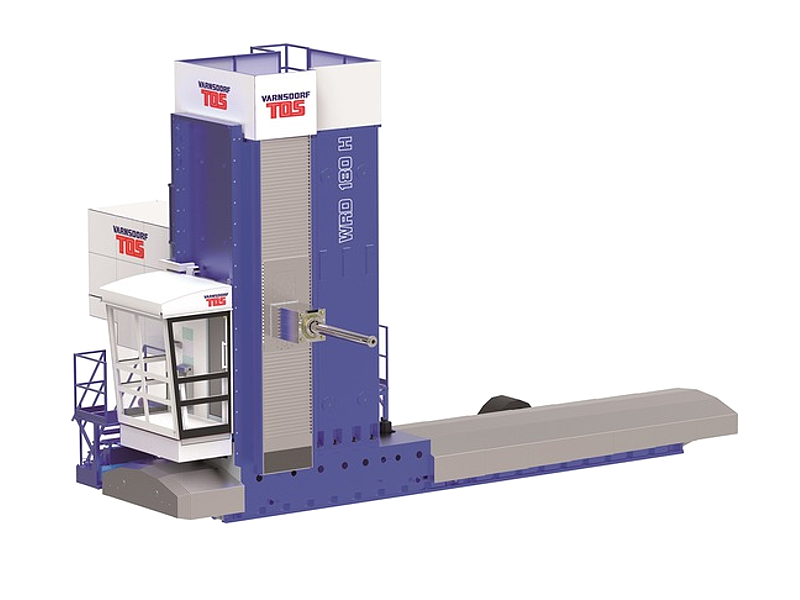

WRD 180 H

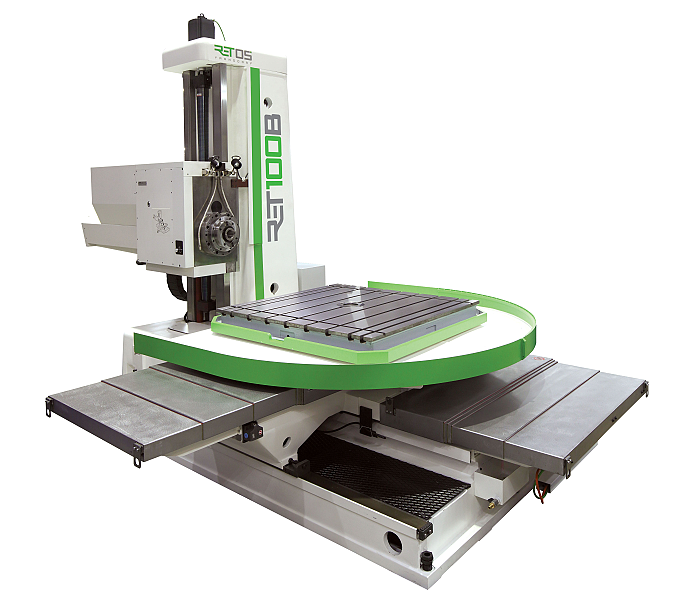

RET100B / W100B

RET10P

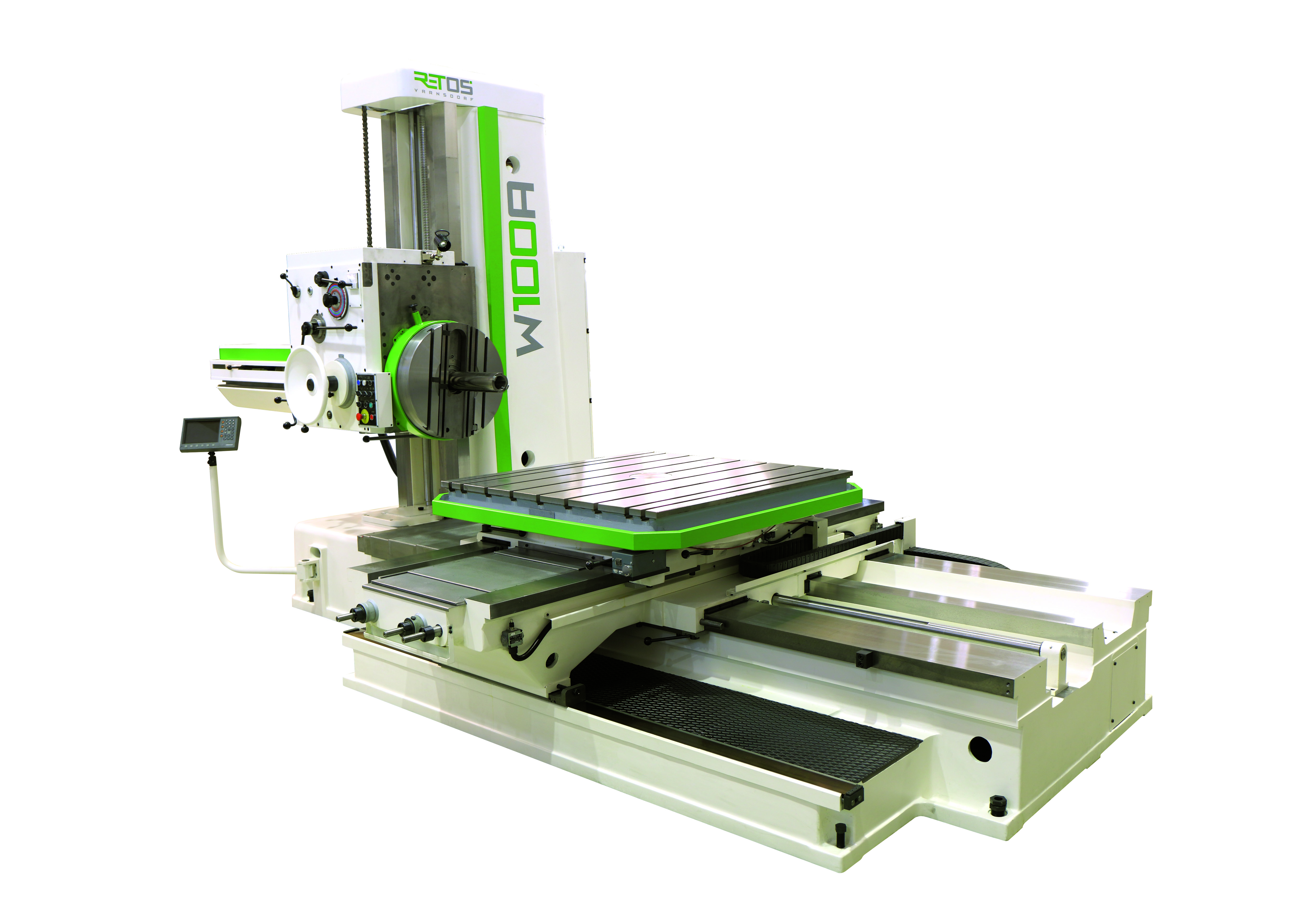

W100 A

RET10X

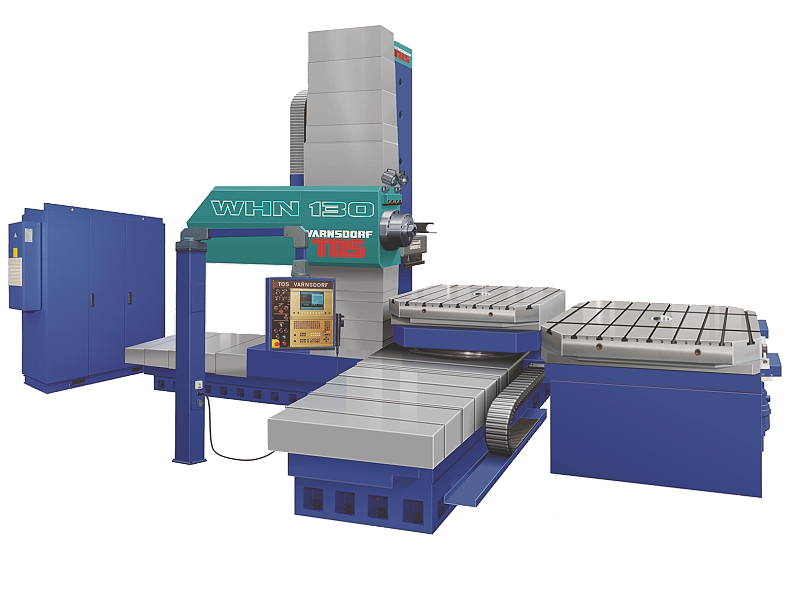

WHN 110 (Q, MC)

WHN(Q) 13/15 CNC

WHN 130 (Q, MC)

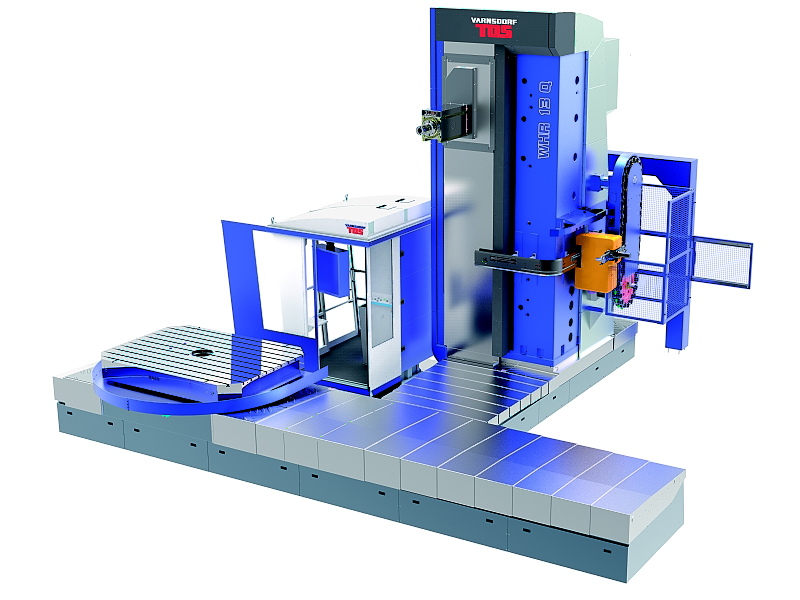

WHR 13 (Q)

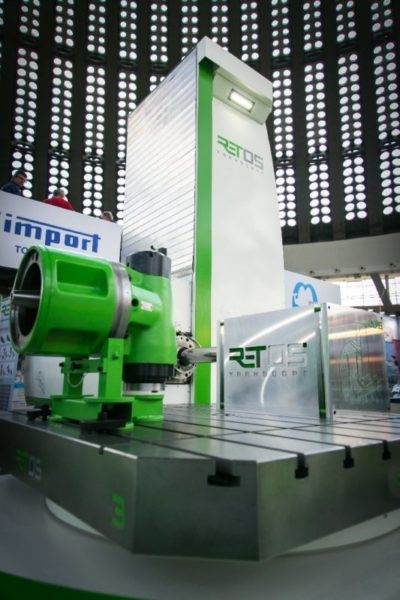

RET 10 X prezentována na našem stánku TENHIKA 2017, Bělehrad, Srbsko