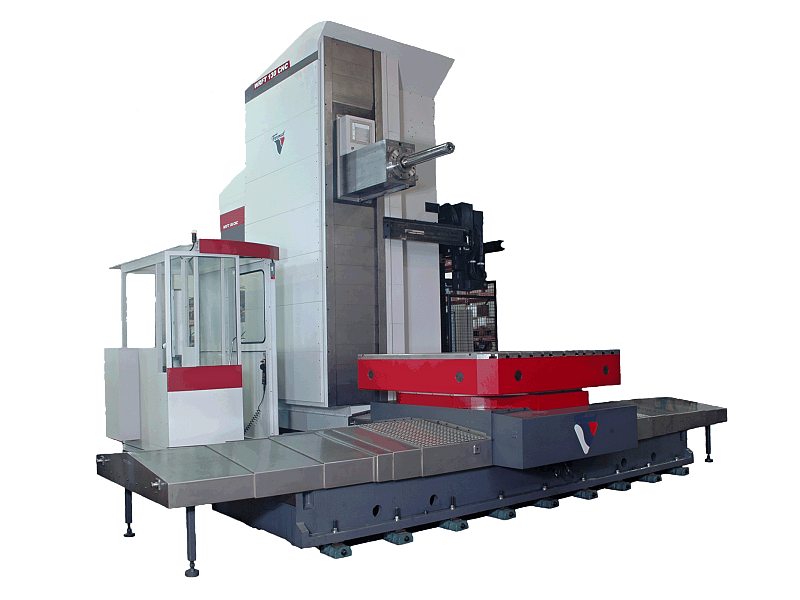

WFT 13 CNC

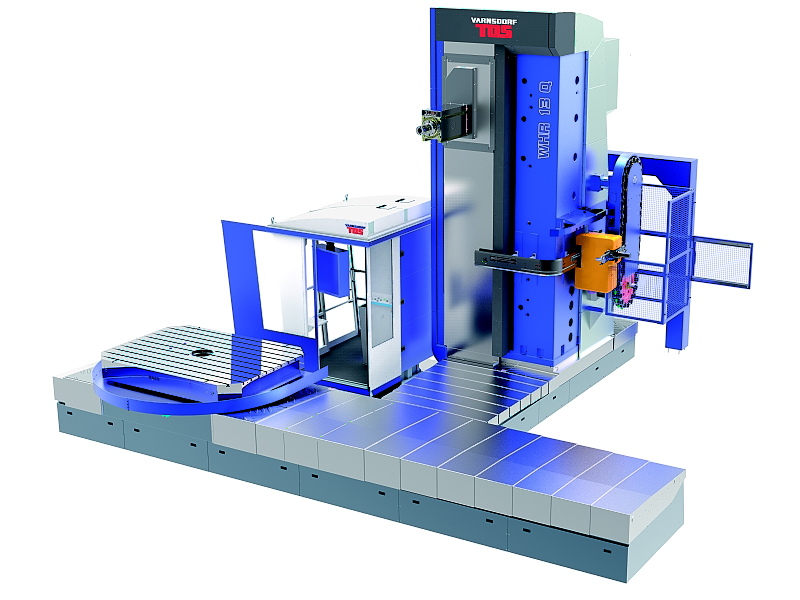

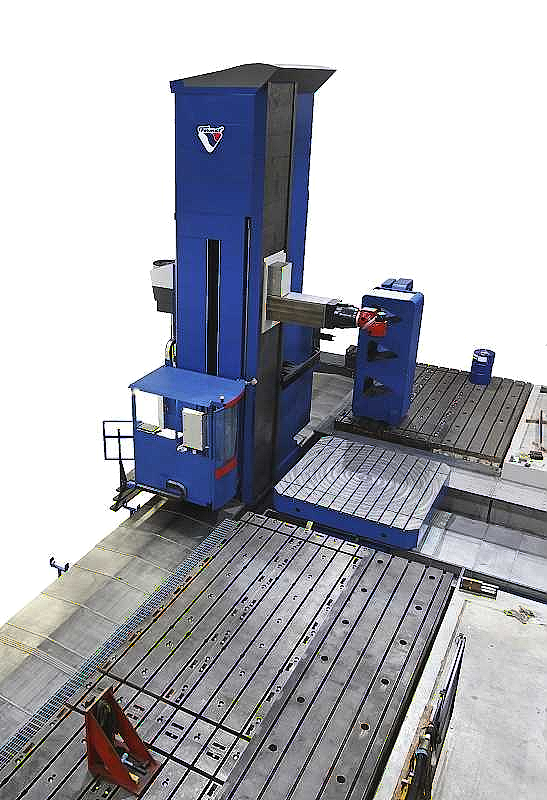

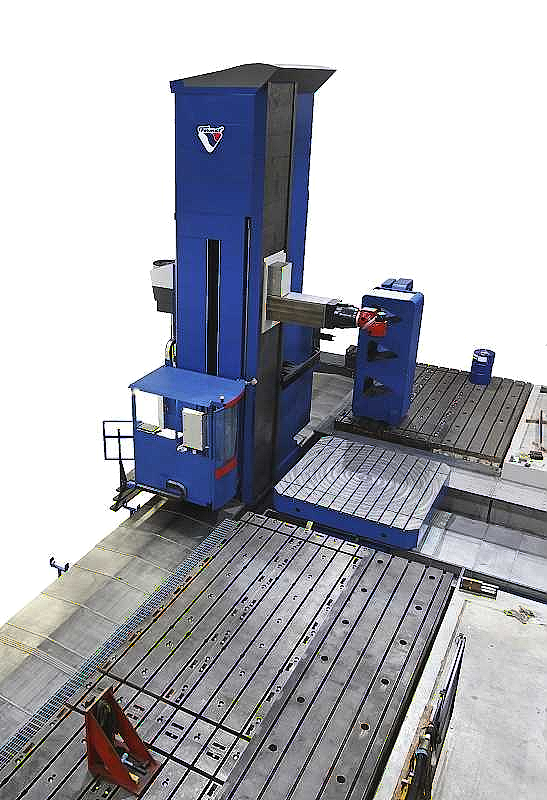

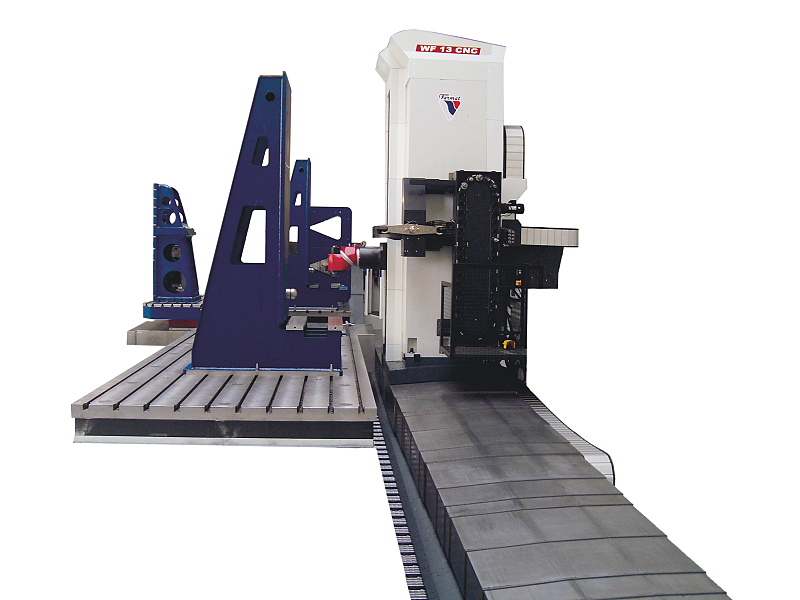

Horizontal boring mill table-type WFT 13 CNC

Horizontal Boring Mill table-type WFT 13 CNC represents the newest technology and concept of horizontal table-type borers that are currently on the market.

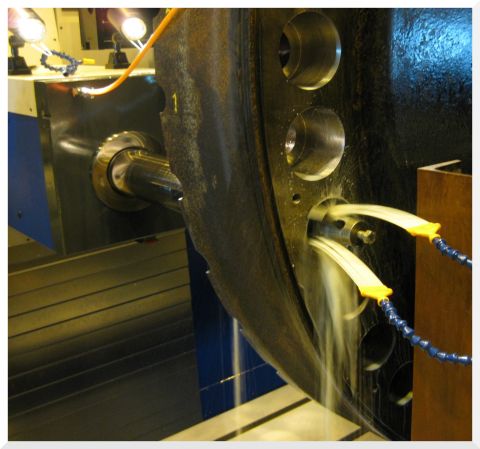

The WFT 13 CNC horizontal boring mill is a continuously controlled table type milling and boring machine with a travelling spindle for the W axis, a longitudinally movable column base for the Z axis, and a table movable in a crosswise way for efficient machining of workpieces of up to 20 Tons on the X axis.

Thanks to the powerful headstock, high axial forces and most precise table in its category, Fermat WFT 13 can fulfill the needs of the most demanding customers.WFT 13 offers four linear and one rotary axis travel (X, Y, Z, W and B). A full servo rotary table option allows continuous B-axis rotation (contouring) simultaneously with X, Y, Z, or W axes. Because of its modern design, WFT 13 is a universal boring and milling machine that allows efficient processing of large and heavy workpieces while utilizing high precision and quality of operation.

CNC system:

Quality CNC systems provide easy manipulation of the machine and many useful functions for the user. A consistent control of the machine is provided by a CNC system according to the customer’s choice (HEIDENHAIN iTNC 530, SIEMENS 840D SL or FANUC 31i B) with an English dialogue. A standard is the control of linear axes X, Y, Z, W, rotary coordinates for the positioning of the table (B axis) and the work spindle rotation (C axis). The control panel on a rotary bracket is equipped with a color 15’’ screen. Standard equipment includes a portable control console – a hand wheel (type according to the CNC system including a possibility of wireless transmission).

The main framework

The main framework of the machine (the longitudinal and cross-wise beds, slides and the column base) are made of cast iron GG30 with the addition of Cr and Cu; the functional surfaces of all the ways of the box guides is hardened (56 HRC) and ground. The width of the box ways on the X and Z axes is always 300 mm and the span of their outer edges is 1200 mm. The width of the box ways on the Y axis is 180 (in the front) and 130 (in the back) mm and the span of their outer edges is, again, 1200 mm. The headstock slide is moved in a vertical direction upon the box ways of the frame.

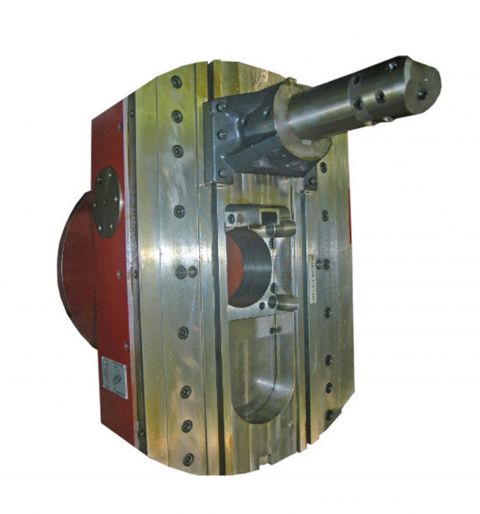

The headstock

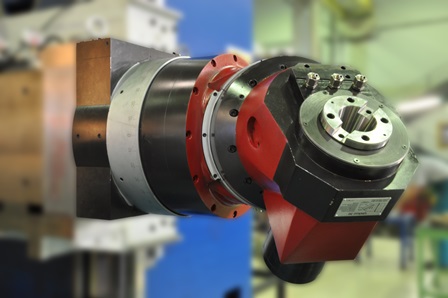

The headstock is of a prism shape, the framework of the headstock is made from cast iron GGG60. The work spindle with the clamping spindle taper SK50 (the clamping is made according to the customer’s wish: ISO/BT/CAT) is nitrided and machined with an exceptionally high accuracy (0,005 mm tolerance). It is placed in high precision angular ball bearings of the spindle. The bearings of the main seating of the spindle are grease packed. The spindle bearings are thermally stabilized by an oil bath through a separate cooling aggregate. The spindle is equipped with automatic clamping of the tools utilizing disk springs with a multiplier of clamping power, the release of the tool is provided by a hydraulic cylinder.

FRM Upínací úhelníky

FRM Upínací desky

FRM Pick Up

FRM Obrobkové a nástrojové měřící sondy

FRM Lícní desky

FRM Chlazení

FRM Frézovací hlavy

FRM ATC

FRM APC

HCW1, HCW2, HCW3, HCW4

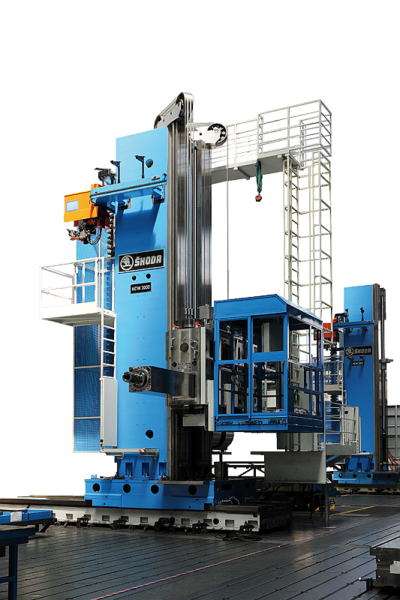

HCW 2000, HCW 3000, HCW 4000

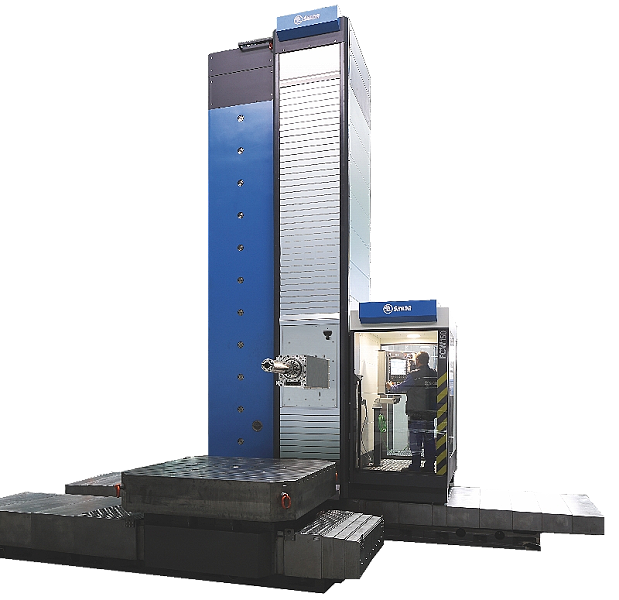

FCW 140, FCW 150, FCW 160

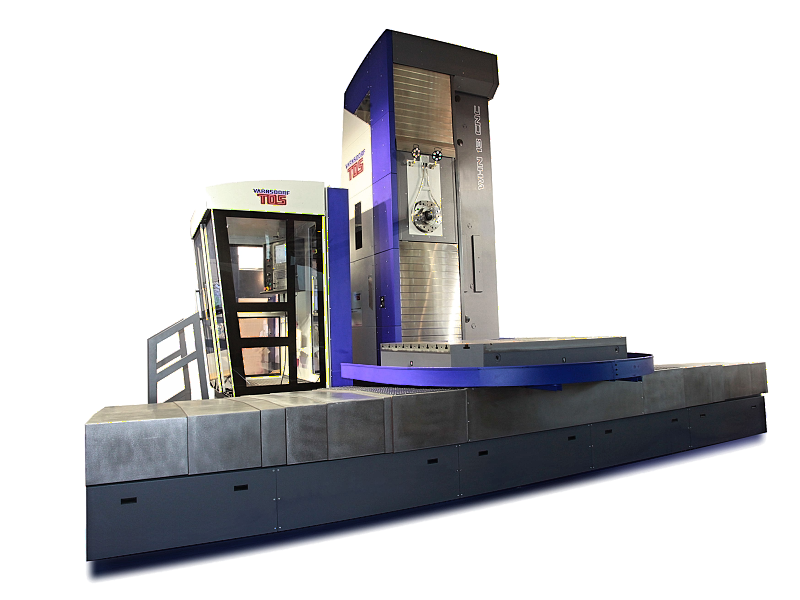

WRFT 130 CNC

WFT 15 CNC

WFT 13 CNC

WFT 11 CNC

WRF 160 CNC / WRF 160 HEAVY

WRF150 CNC

WRF 130 CNC

WF 13 CNC

WFC 10 CNC

Maxima

WRD 13 (Q)

WRD 130 / WRD 150 (Q)

WRD 170 (Q)

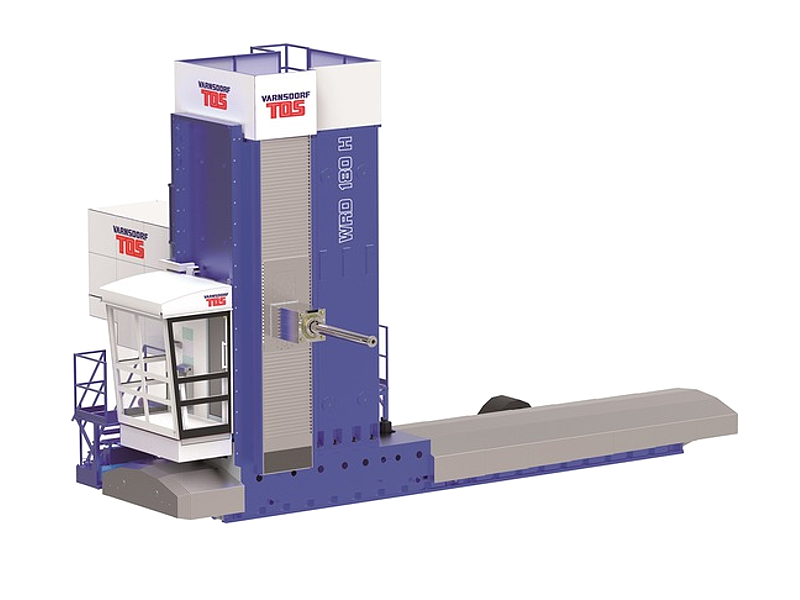

WRD 180 H

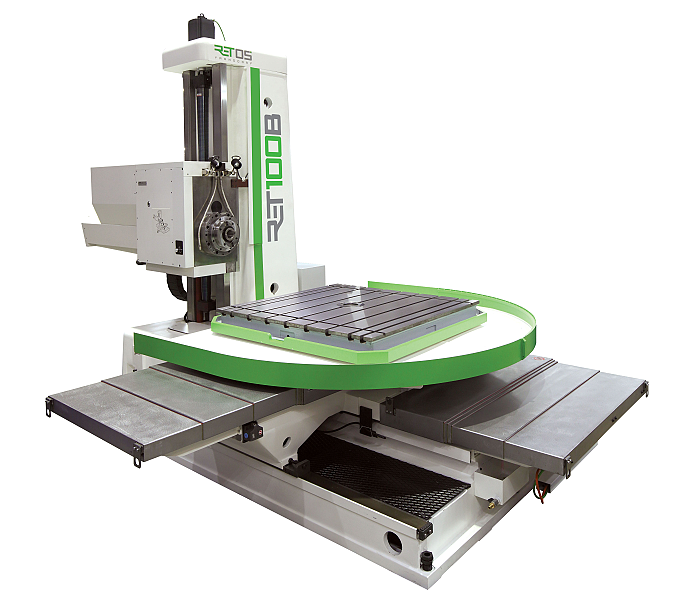

RET100B / W100B

RET10P

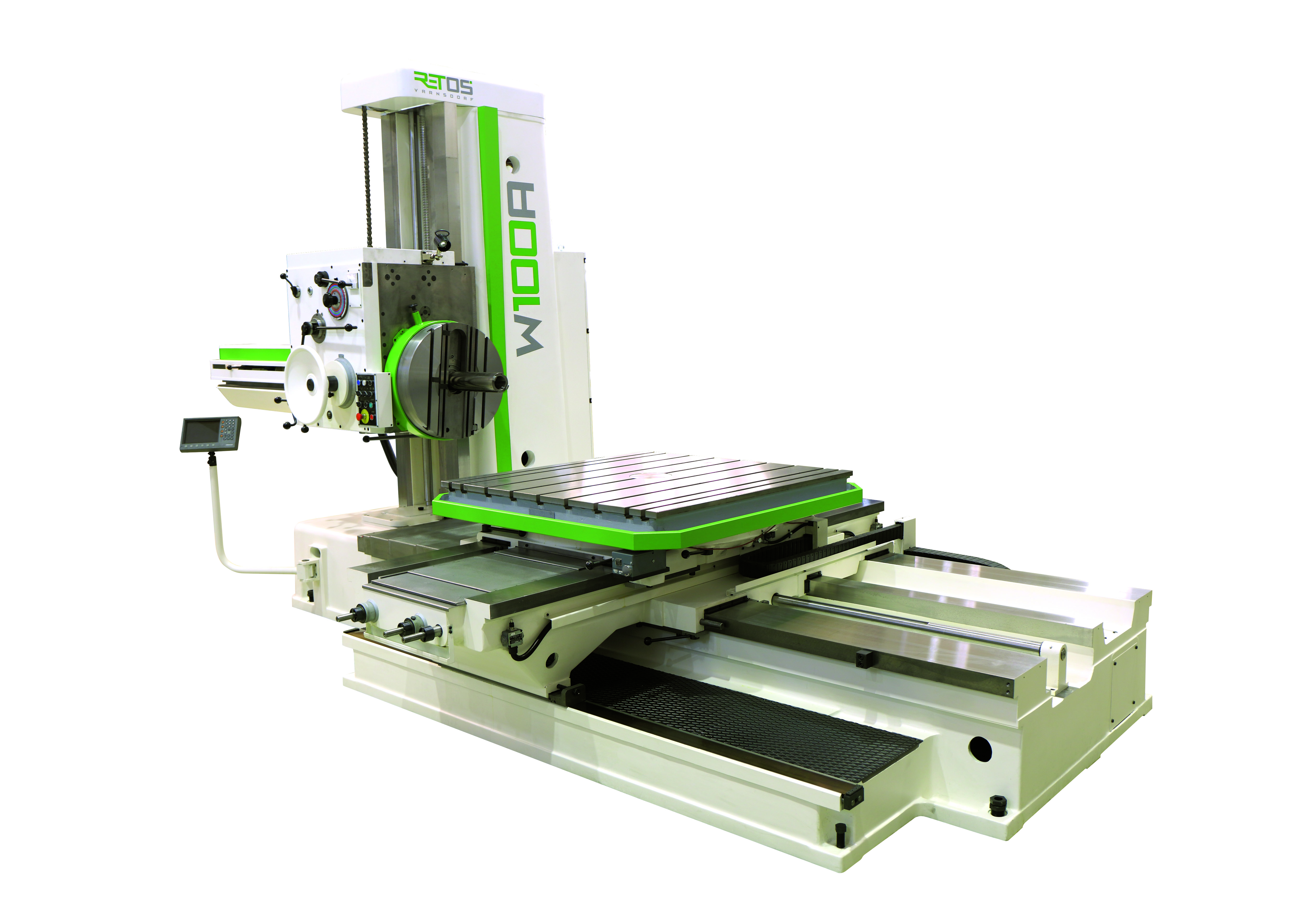

W100 A

RET10X

WHN 110 (Q, MC)

WHN(Q) 13/15 CNC

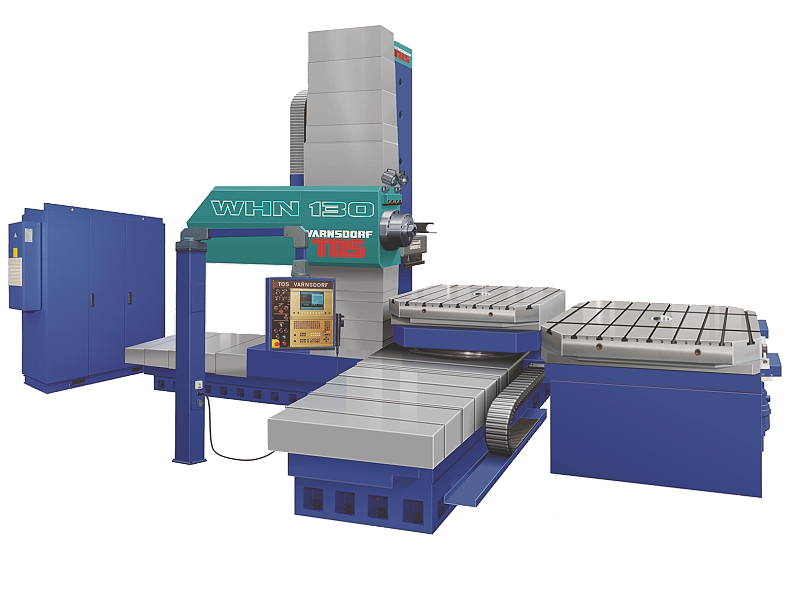

WHN 130 (Q, MC)