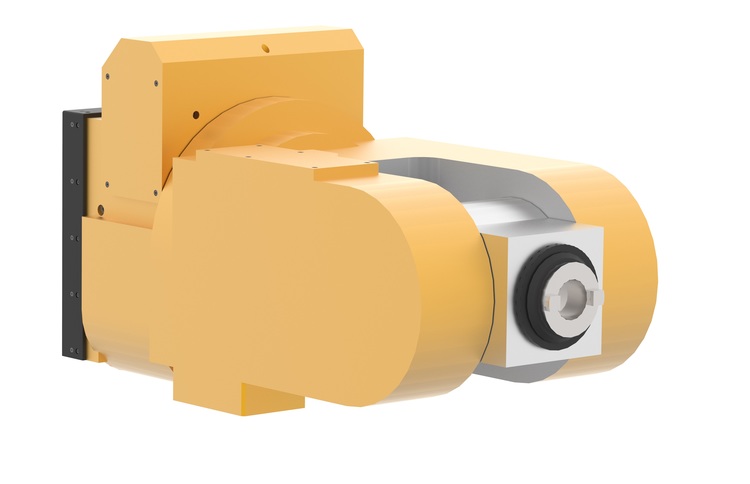

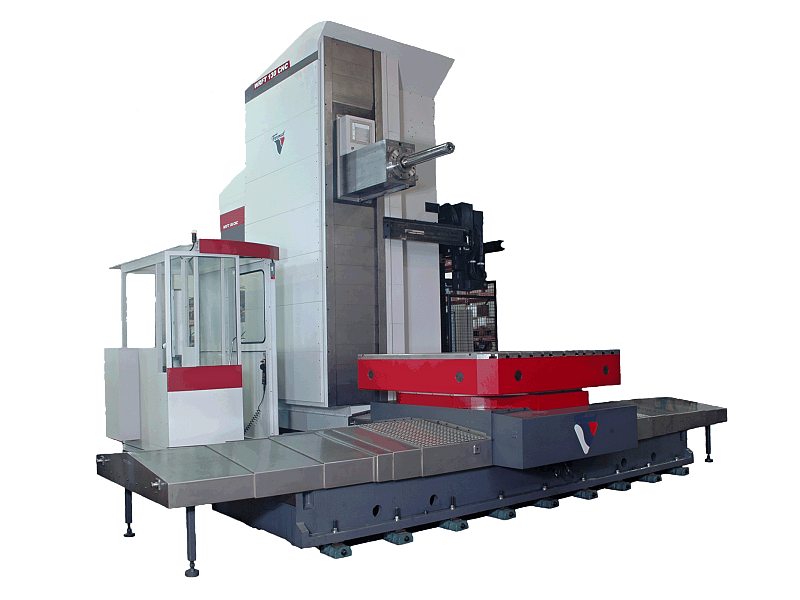

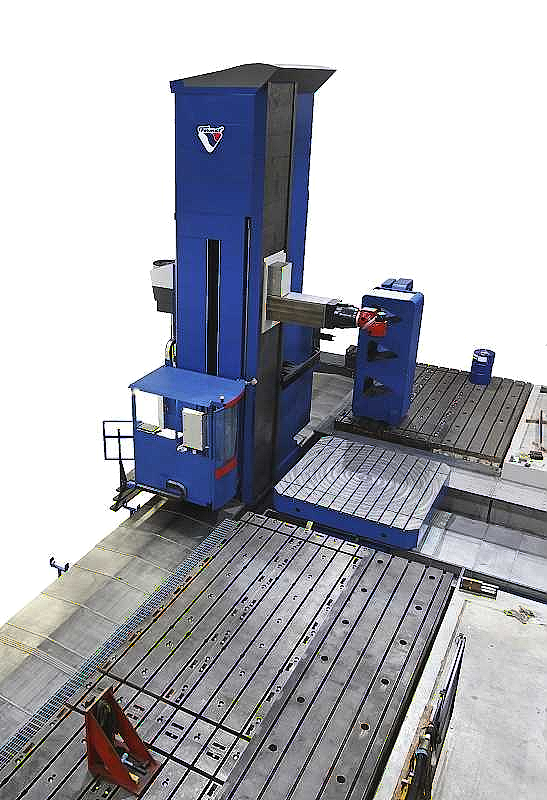

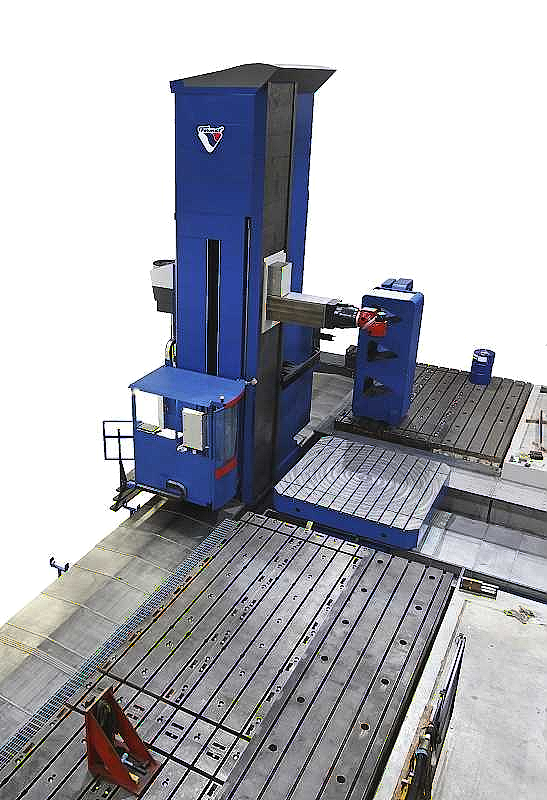

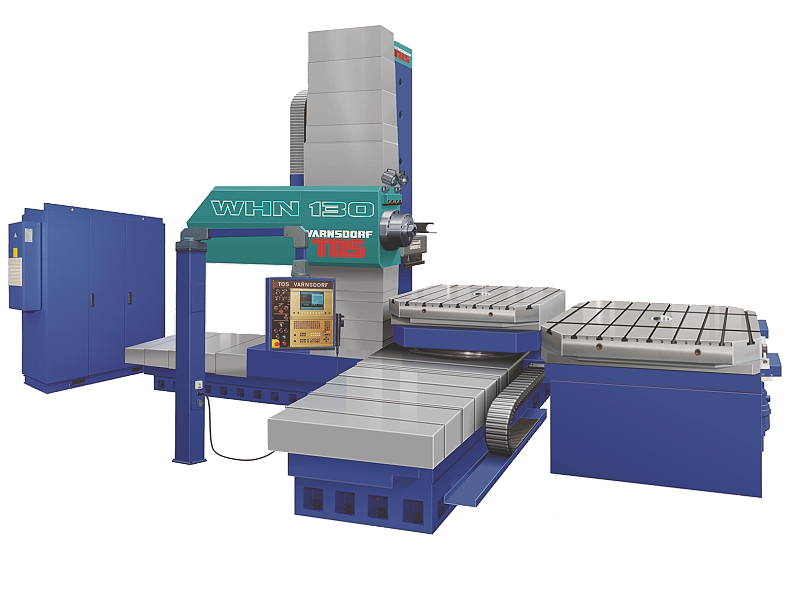

WHN(Q) 13/15 CNC

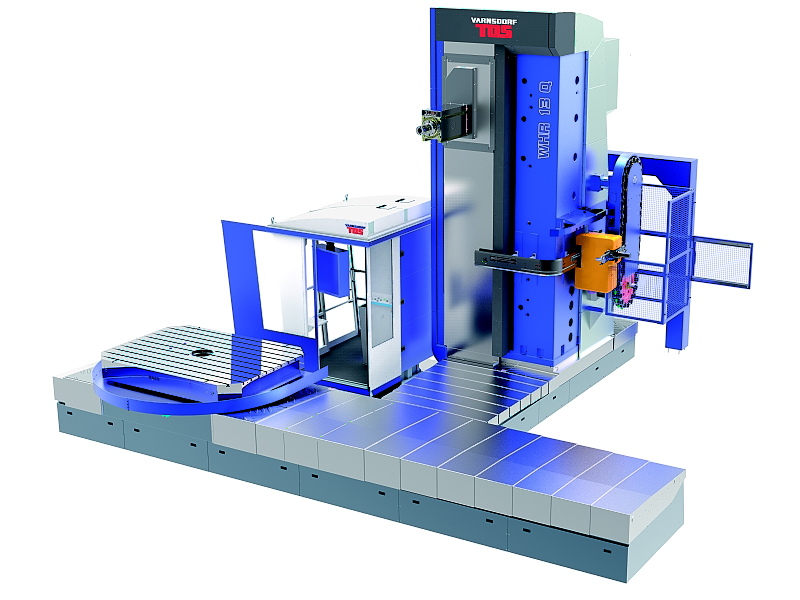

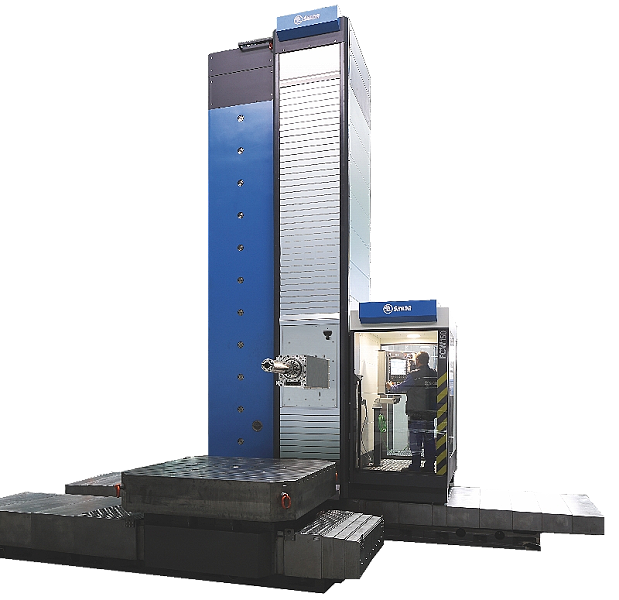

Horizontal milling and boring machine WHN (Q) 13/15 CNC

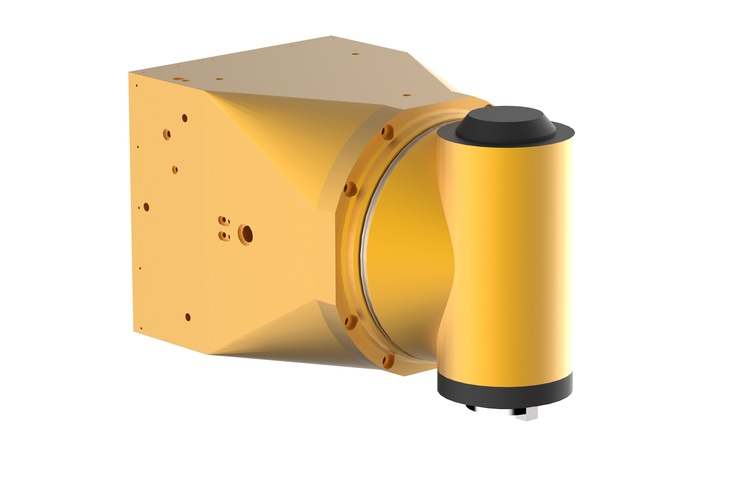

WHN (Q) 13/15 CNC – The horizontal milling and boring machine is a universal machine designed for precise milling, line-coordinate drilling, boring and thread cutting of box- and board-type workpieces as well as complicated workpieces from cast-iron, steel cast-iron and steel with the weight of up to 25,000 kg. The success of this machine can be documented by the fact that almost 2,500 of these machines have been made up to now. It particularly excels in the ratio between capacity and the purchasing costs. The users value the structure of the machine, which guarantees high rigidity and reliability as well as high technical parameters and a broad range and comfort of the technological features. The machine can be supplemented with a series of options, which greatly extend the machine‘s potentialities.

- WHN 13/15 CNC – the basic model

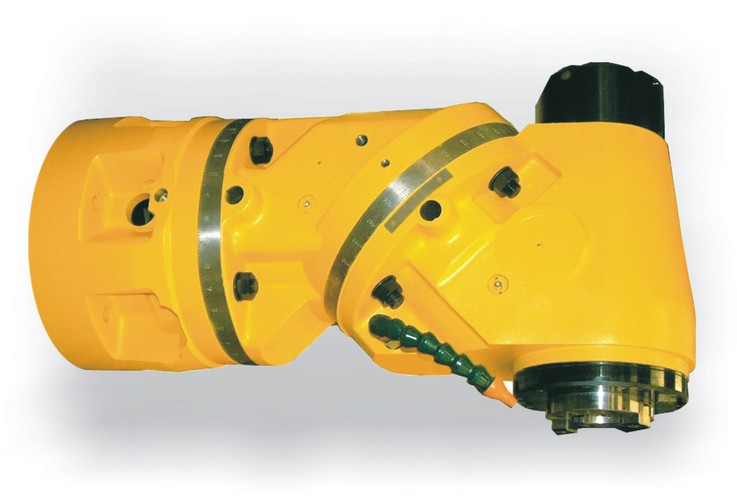

- WHQ 13/15 CNC – the Automatic Tool Changer (ATC) equipped model

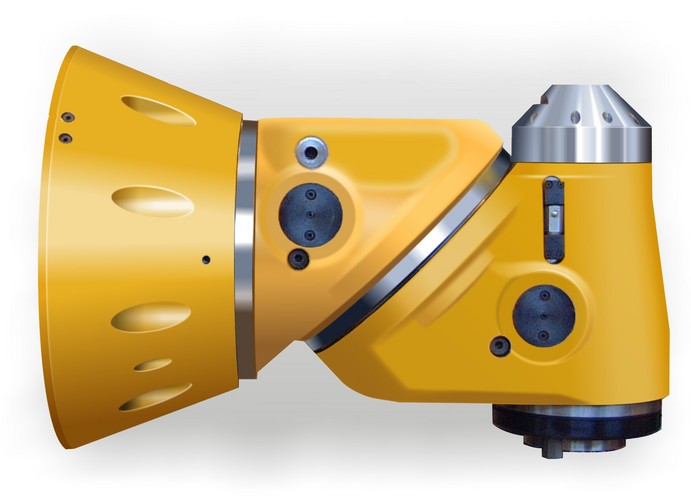

- WHN 13/15 MC – the full-fledged machining center equipped with both, ATC and APC

-

the most successful machine (more than 2,000 produced machines)

- universal machine tool for precise milling, coordinate boring, the boring and cutting of box and plate plate screws and comlicated workpieces with weight of up to 25,000 kg

- machine can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value

- either SINUMERIK 840 D SL, HEIDENHAIN TNC 640 or FANUC 31i control system can be selected for controlling the machine

VDF UU

VDF UK

VDF UD4

VDF VPK

VDF SZP

VDF RENISHAW

VDF Dopravník třísek

VDF LD650

VDF CHOV

VDF UFP 40-10 (UFP 50-13)

VDF FP40-10 (FP 50-13)

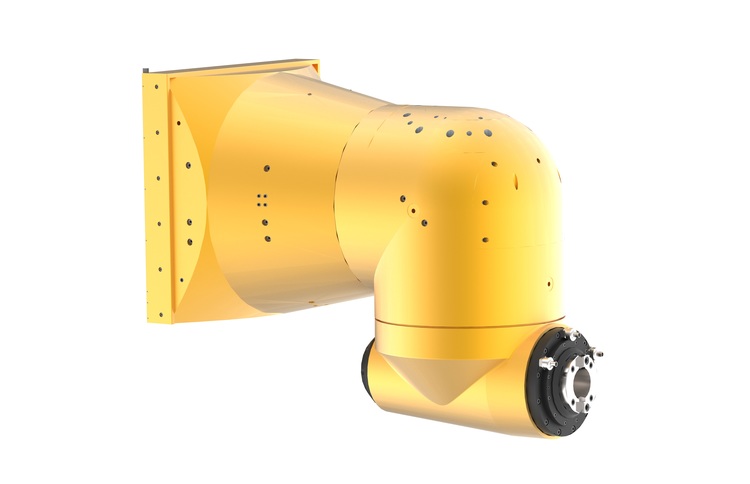

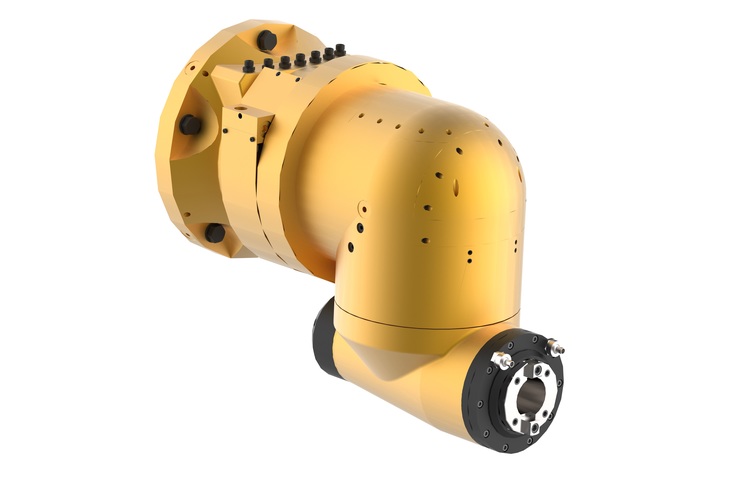

VDF frézovací hlava HV/V

VDF frézovací hlava HV/EH

VDF frézovací hlava HUR50

VDF frézovací hlava HUI50

VDF frézovací hlava HUF50

VDF frézovací hlava HPR50

VDF frézovací hlava HPI50

VDF frézovací hlava HOIT50

VDF frézovací hlava HOIL50

VDF frézovací hlava HOI50

VDF frézovací hlava HOF50

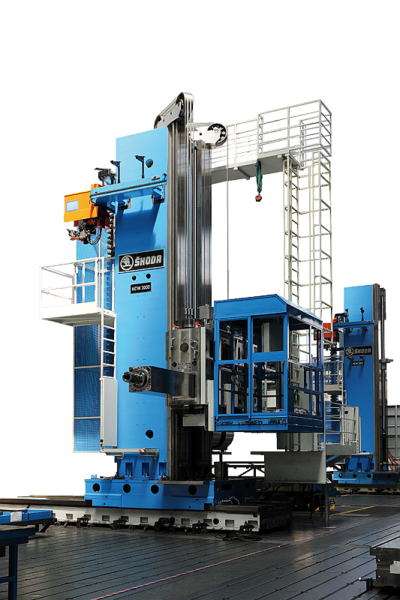

HCW1, HCW2, HCW3, HCW4

HCW 2000, HCW 3000, HCW 4000

FCW 140, FCW 150, FCW 160

WRFT 130 CNC

WFT 15 CNC

WFT 13 CNC

WFT 11 CNC

WRF 160 CNC / WRF 160 HEAVY

WRF150 CNC

WRF 130 CNC

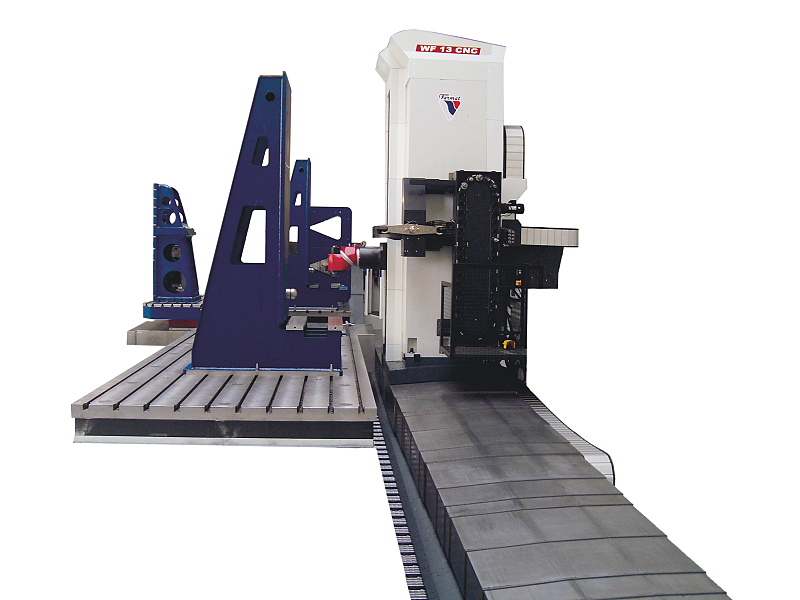

WF 13 CNC

WFC 10 CNC

Maxima

WRD 13 (Q)

WRD 130 / WRD 150 (Q)

WRD 170 (Q)

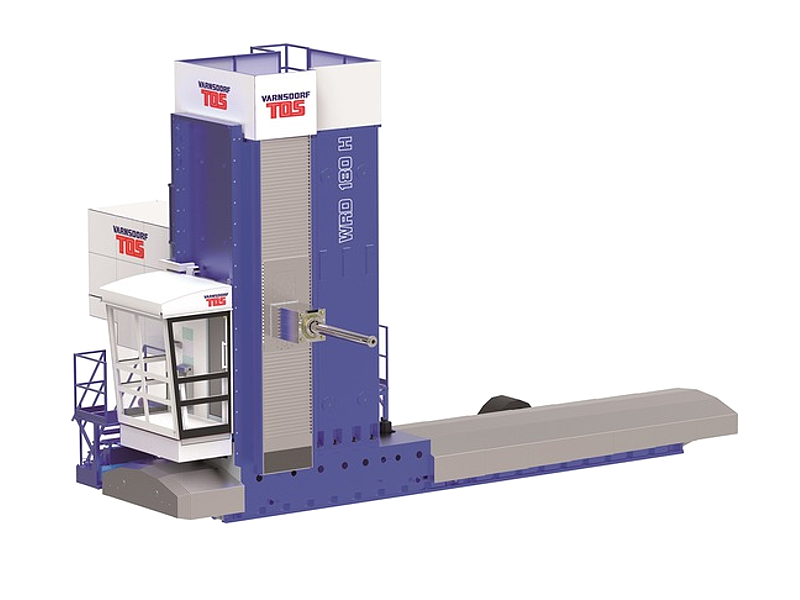

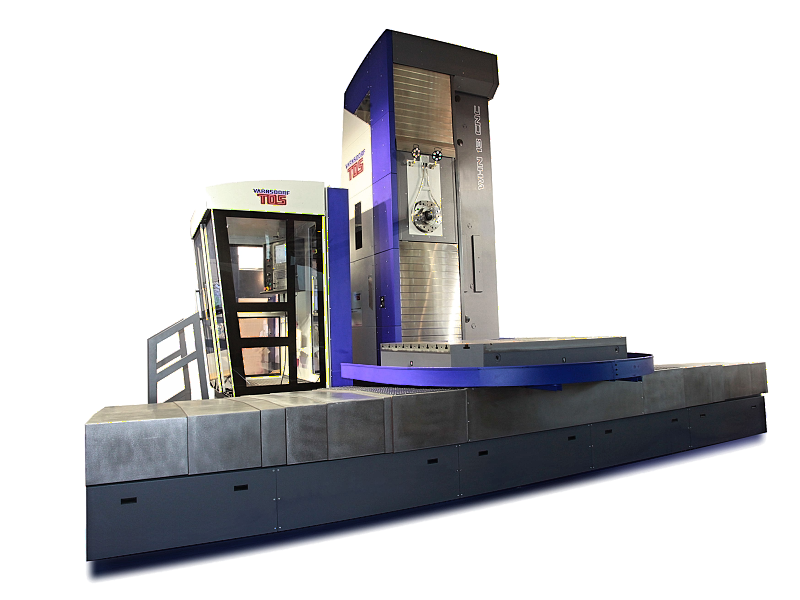

WRD 180 H

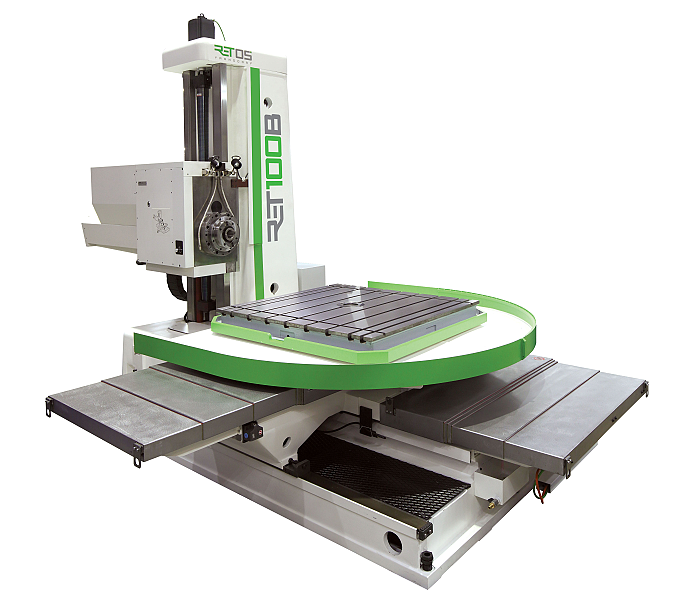

RET100B / W100B

RET10P

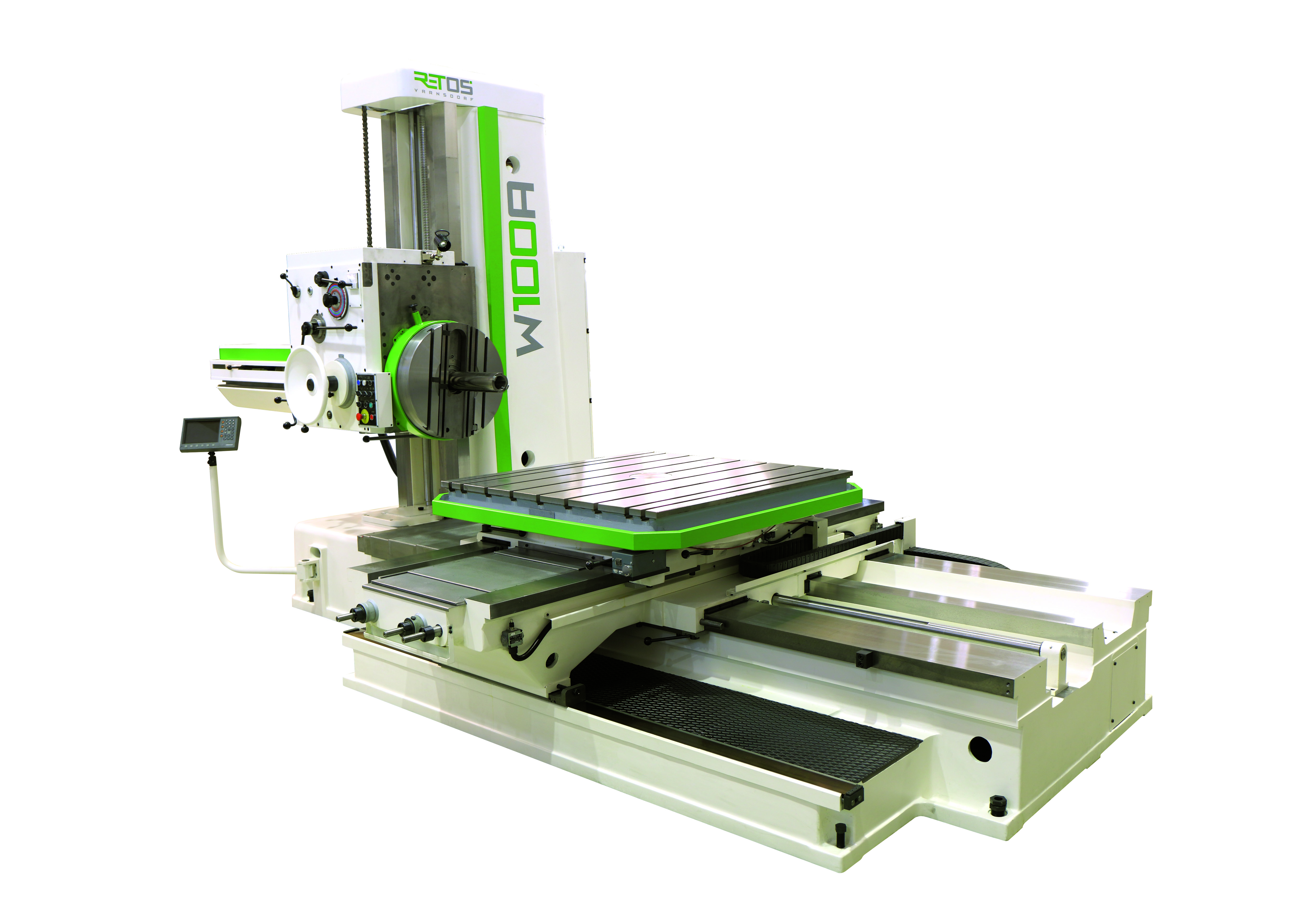

W100 A

RET10X

WHN 110 (Q, MC)

WHN(Q) 13/15 CNC

WHN 130 (Q, MC)