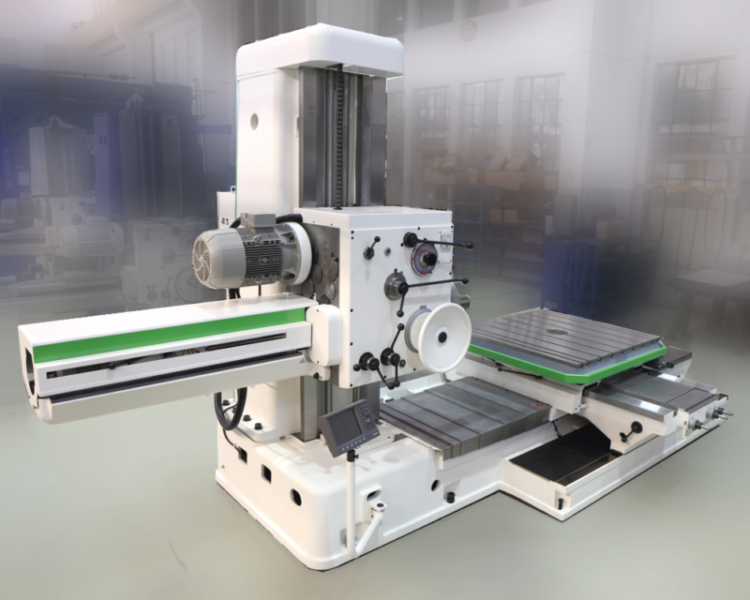

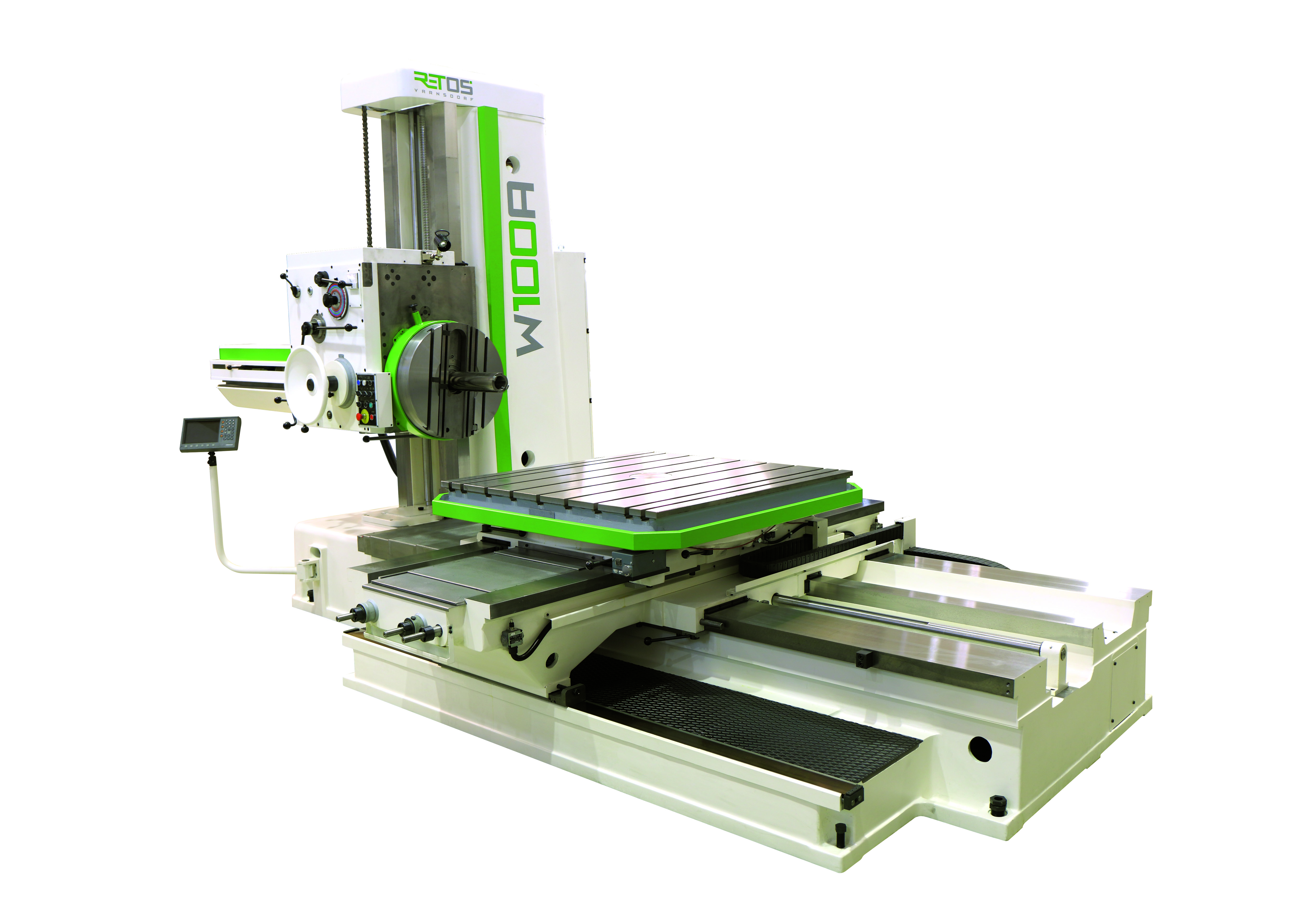

W100 A

Conventional horizontal boring mill W100A

W100A – Conventional horizontal boring mill with fixed column and crosswise travelling table. Have four linear axes plus rotary table. Machine designed for piece and low-volume engineering production, suitable for roughing as well as for finishing. Travel in the X axis = 1600 mm.

Features

- manually controlled horizontal boring machine

- fixed column, crosswise travelling table

- 4 linear axes, rotary table

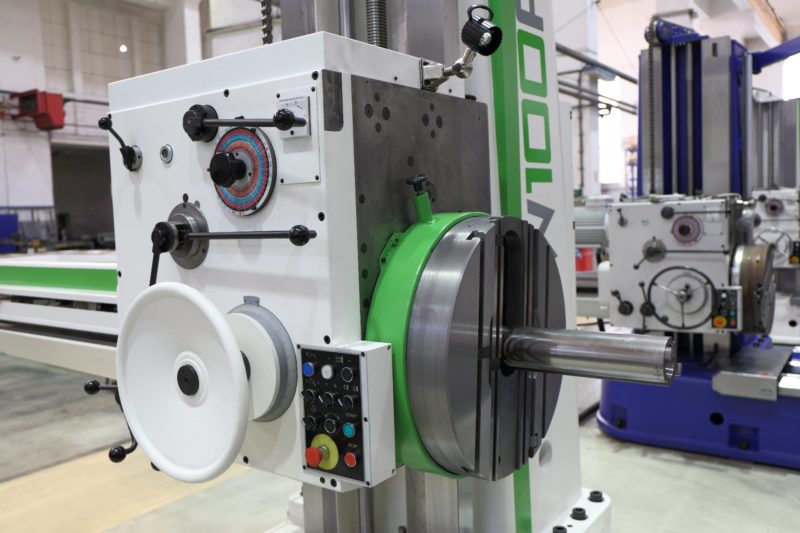

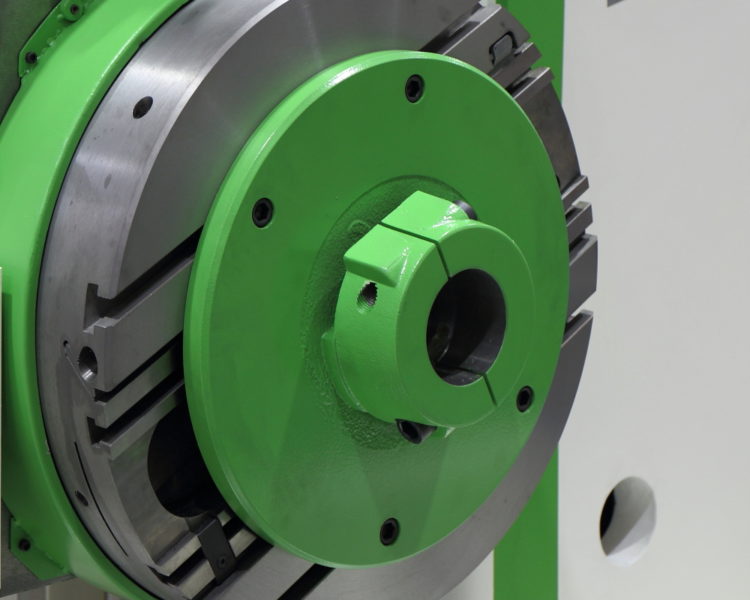

- sliding workspindle

- facing head with tool slide

- machine designed for piece and low-volume engineering production

- suitable for roughing as well as for finishing

- digital optical admeasuring of linear axes and table rotation with DROs

- optionally can be fitted by f.e. tool cooling kit (CHZ), outboard support, spindle clamping / guiding support, rectangular milling head etc.

Configuration

Travelling Groups

- X – travel of rotary table slide on saddle

- Z – travel of saddle on bed

- Y – vertical headstock travel on column

- W – spindle stroke

- U – travel of tool slide of facing head

- B – table rotation

- S – rotation of workspindle and facing head

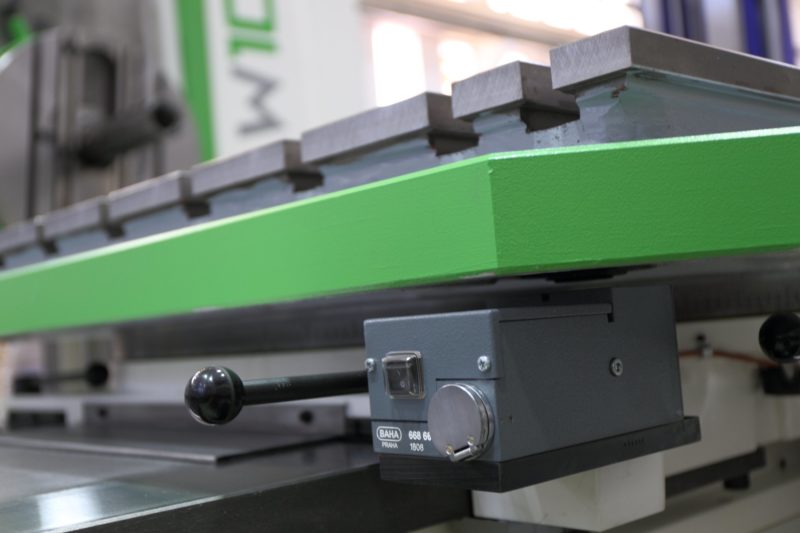

Group Guidance

- guideways on all linear axes are ground, counterways with synthetic casting

- guideways on bed and saddle reinforced with hardened steel plates

- guideways of rotary table and facing head are scrapped

Lubrication

- HYTOS lubrication set

- central, time powered by PLC in electric cabinet

- lubricates X, Y, Z, W, B axes

- U axis lubricated by grease nipples

Clamping

- X, Y, Z, W, B axes – manually by levers

Optional accessories

- portable control panel PP-100 (necessary to order together with the machine)

- outboard support

- CHZ-100 tool cooling kit

- PVD100-550 spindle guiding support

- SP100 spindle clamping support

- spindle clamping support up to 800 rpm

- FP40-100 rectangular milling head

- UFP40-100 universal milling head

- change gear kit for thread cutting

- TD50 telescopic tool holder

- VT80-2500-ISO50 smooth boring bar

- VT80-3150-ISO50 smooth boring bar

- VT100-2500-ISO50 smooth boring bar

- VT100-3150-ISO50 smooth boring bar

- LLK-150/80 sliding bush of the outboard support

- LLK-150/100 sliding bush of the outboard support

- VH80 three-tool boring head

- VH80-100 three-tool boring head

- VHU-ISO50 universal boring head

- UK500 clamping cube

- UU800, UU950, UU1120 clamping angle plates

- spares kit for 3-year operation

- 2D touch probe KT 130 HEIDENHAIN

- transport bars (in the container necessary)

ReTOS VHU125D

ReTOS VH80

ReTOS VH80, VH100

ReTOS TD50

ReTOS SP100/800

ReTOS SP100

ReTOS RZ100

ReTOS PT880 HEIDENHAIN

ReTOS PP100

ReTOS ND780 HEIDENHAIN

ReTOS ND280 HEIDENHAIN

ReTOS KT130 HEIDENHAIN

ReTOS DN100

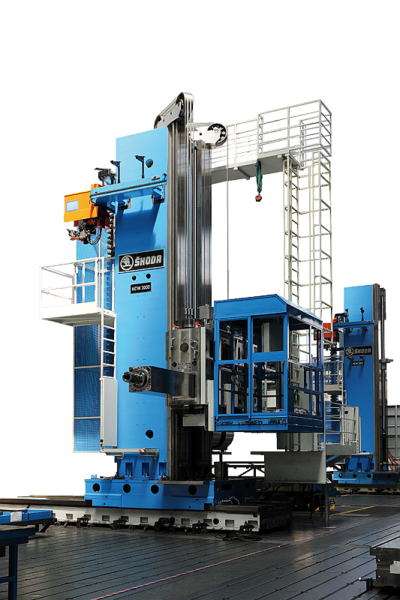

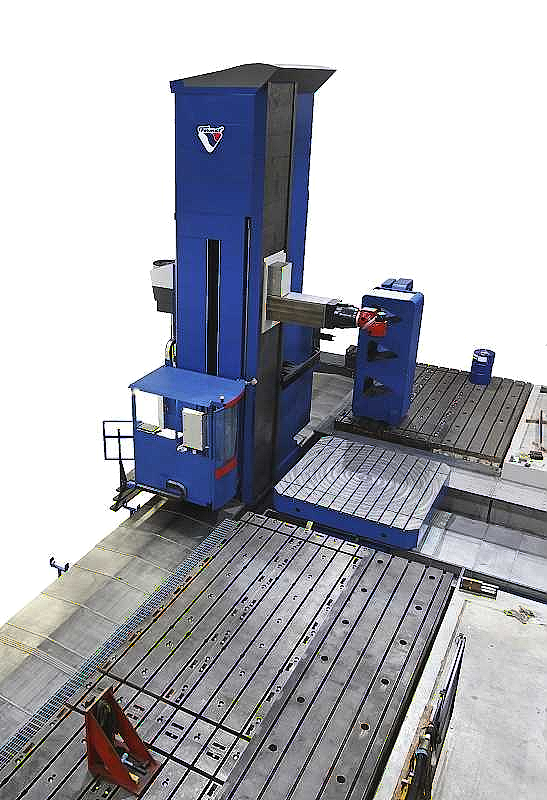

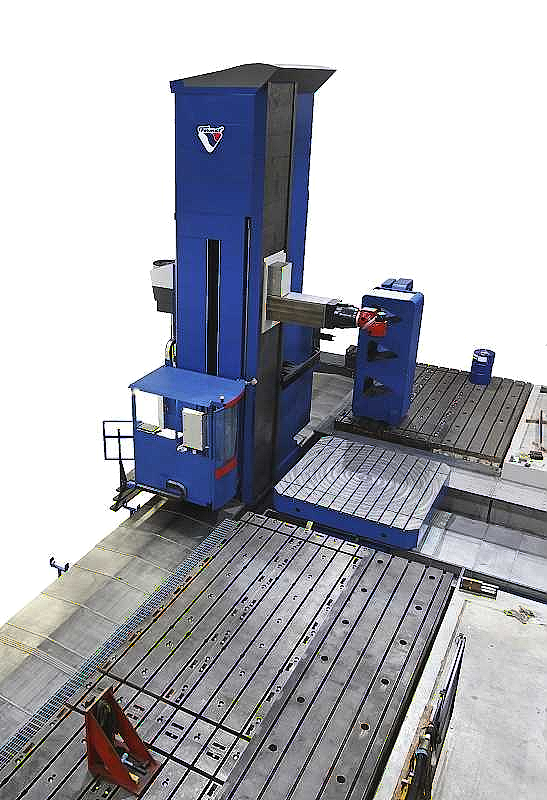

HCW1, HCW2, HCW3, HCW4

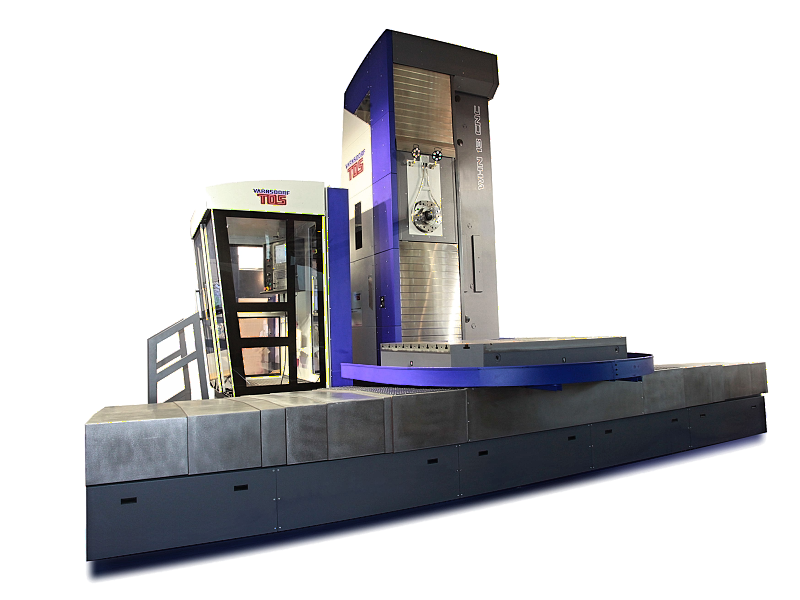

HCW 2000, HCW 3000, HCW 4000

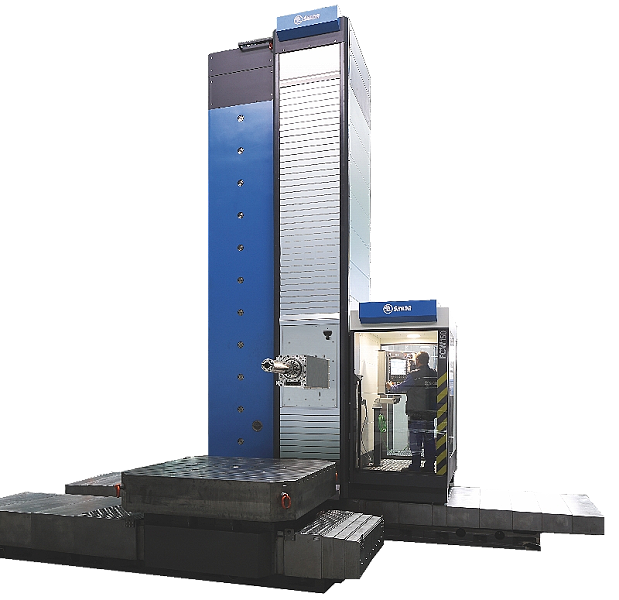

FCW 140, FCW 150, FCW 160

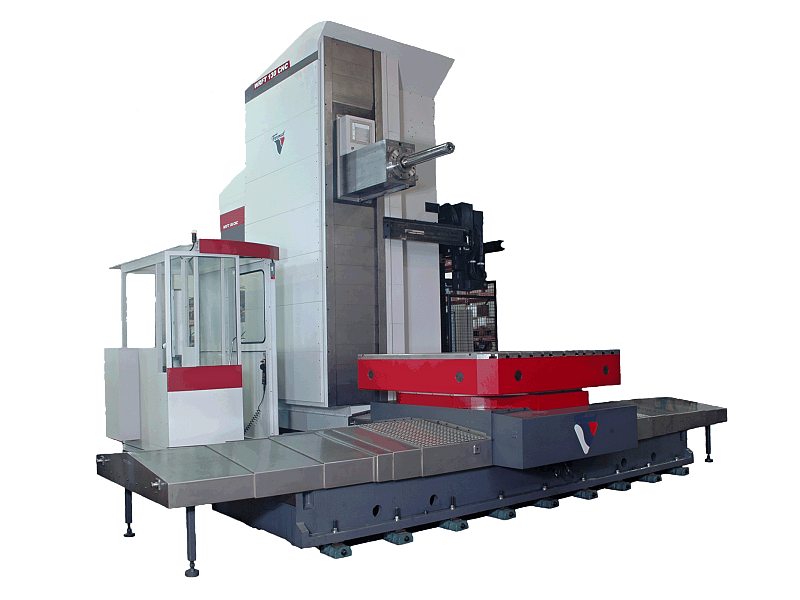

WRFT 130 CNC

WFT 15 CNC

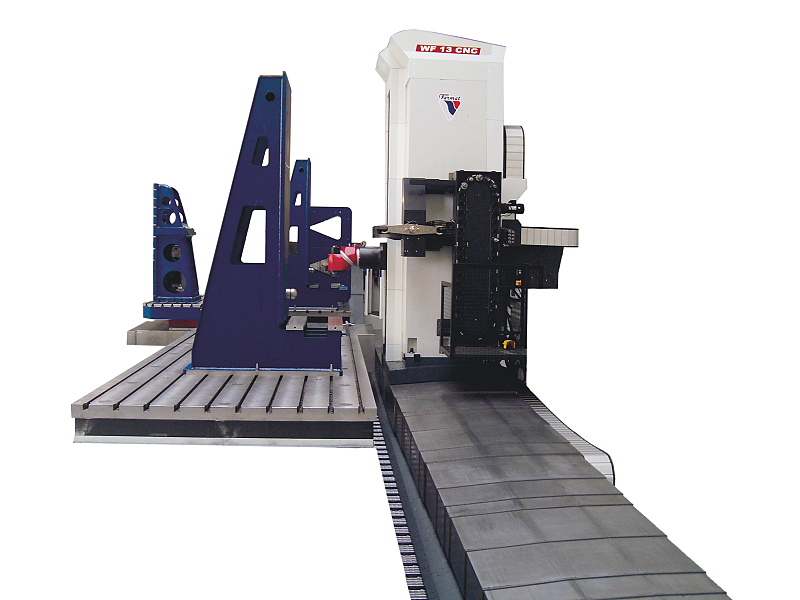

WFT 13 CNC

WFT 11 CNC

WRF 160 CNC / WRF 160 HEAVY

WRF150 CNC

WRF 130 CNC

WF 13 CNC

WFC 10 CNC

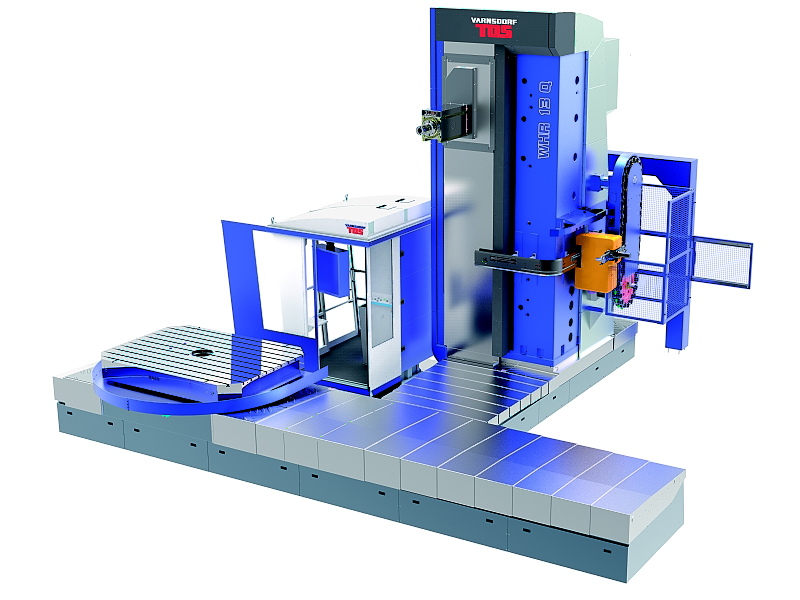

Maxima

WRD 13 (Q)

WRD 130 / WRD 150 (Q)

WRD 170 (Q)

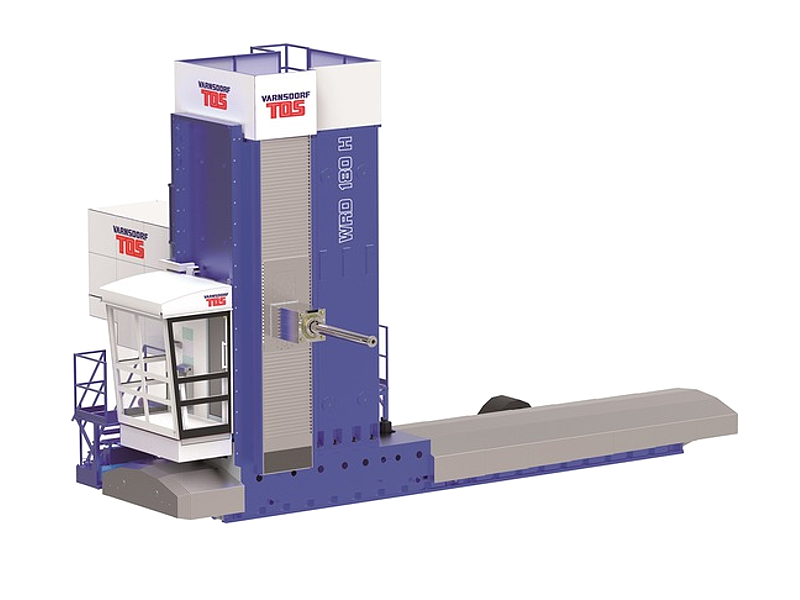

WRD 180 H

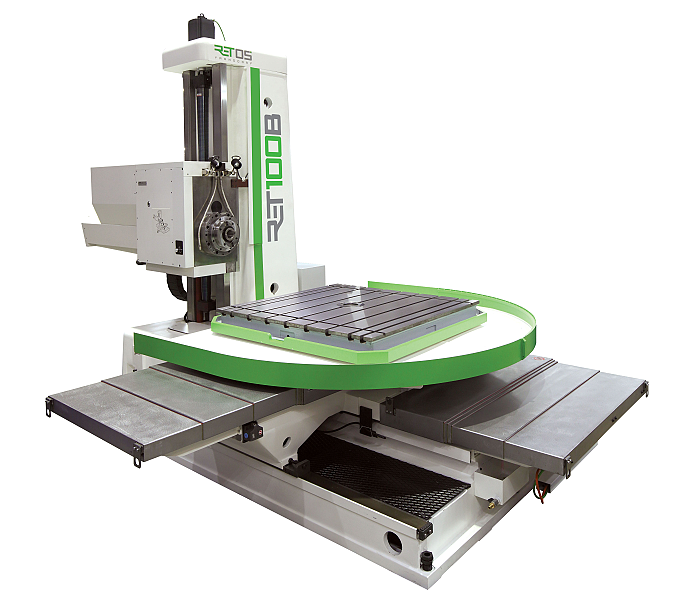

RET100B / W100B

RET10P

W100 A

RET10X

WHN 110 (Q, MC)

WHN(Q) 13/15 CNC

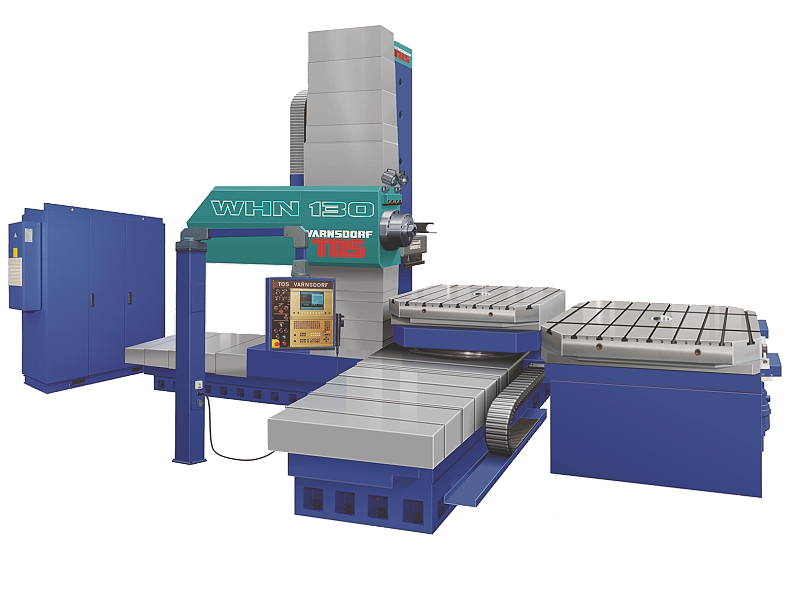

WHN 130 (Q, MC)