MCV 1270 Rapid / Sprint / Speed / Power

3-axis machining centre MCV 1270

MCV 1270 – 3-axis machining centre. Machine is erected on a C-shaped supporting frame. Both confi gurations and profi les of the machine supporting frame castings are optimized with regard to the requirements for high rigidity and stability.

Application of the linear guide in all the linear axes guarantees the required accuracy and dynamics in the machining process.

Highly efficient machining is guaranteed by the use of highspeed spindles and high rapid traverses. Easy approach to the working space thanks to sliding covers which completely open one corner of the working space. Excellent rigidity of the supporting frame allows both heavy duty machining and very precise machining of complicated workpieces.

MCV 1270 is designed for accurate and high speed machining of general shaped surfaces and drilling, boring, reaming, thread cutting and milling of bigger and more intricate parts. ATC (automatic tool changer) enables working in automatic cycle. A cross table and headstock travels can be used simultaneously. Options using, enables parts to be machined from four sides, in addition, it enables helix machining and use of effective cooling with a cooling through spindle.

MACHINE WORKING AMBIENT

The machine is designed to work in a normal workshop ambient, without influence of aggressive fumes and dust particles. The temperature should be kept in a range from + 5° to 35°C, average temperature must not exceed 35°C by max. air humidity of 80%. The machine accuracy is guaranteed at working environment temperature 20 +/-3°C.

CHARACTERISTIC MACHINE DESIGN FEATURES

- movable machine parts (slides, table and headstock) seats on a roller linear guideways

- spindle unit is placed on accurate bearings with oblique contact

- digital AC drives HEIDENHAIN driving spindle and axes

- positioning by means of linear scales

- tools center clamping

- control system HEIDENHAIN TNC 640

STANDARD ACCESSORIES

- electric equipment 3x 400 V/50Hz

- CNC control system HEIDENHAIN TNC 640

- digital AC drives HEIDENHAIN for axis X, Y, Z

- linear scales in axes X, Y, Z

- cooling unit for external cooling

- centric tool clamping

- automatic lubrication of moveable parts

- electronic hand wheel

- ETHERNET card

- accompanying documentations to sub-deliveries (English version only available)

- thermal compensation

- tool kit

- accompanying documentation (note – manual from control system on CD)

- re-cooling of the spindle

- chip conveyor

- tool magazine with mechanical arm

MC1040V

MCG 1000

MCG 820

MCG 810

MCH 1000 FIVE AXIS

MCH 1000

MCH 800 Five Axis

MCH 800

MCH 630

MCV 1000 5 AX

MCU 1100V(T) – 5X

MCU 700V(T) – 5x

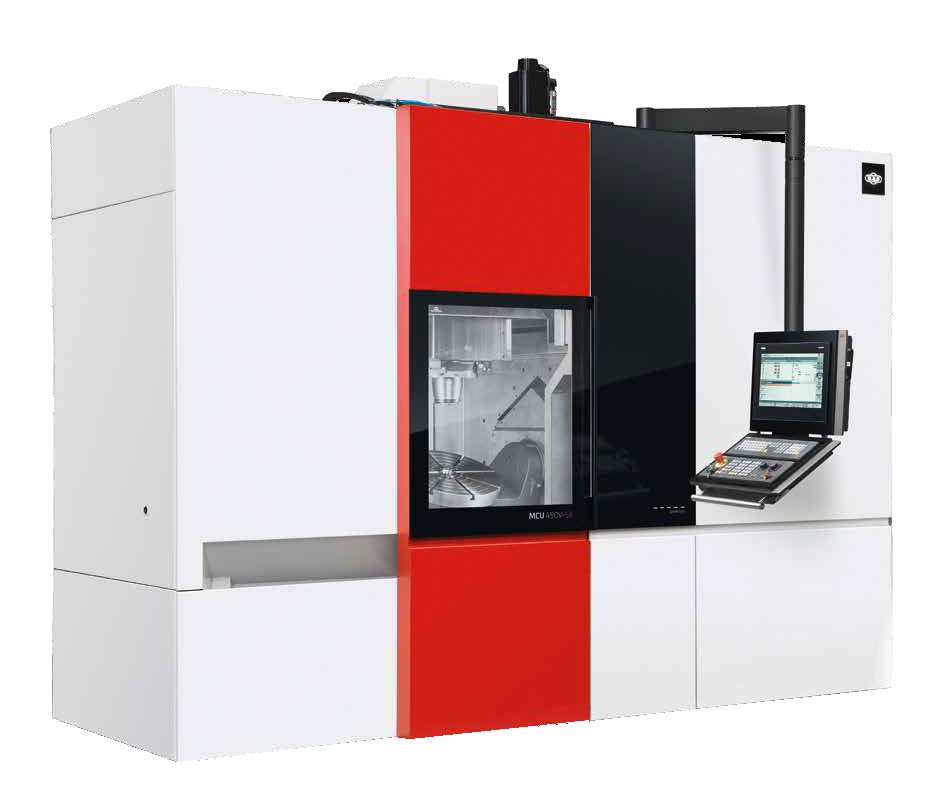

MCU 450V(T) – 5x

MCV 1016 Quick

MCV 1270 Rapid / Sprint / Speed / Power

MCV 800 Quick

MCV 754 Quick

MCV1000 Rapid / Sprint / Speed / Power

MCV 750

MCG 3022

MCG 2318

MCV 2080

MCV 1680

MCV 1260