SE520 SL

SE520 SL – CNC UNIVERSAL LATHE

These machines combine advantages of universal lathes and CNC lathes. The machine works as anuniversal lathe, in manual mode, being controlled by the hand wheels. If required, the operation mode canbe shifted to the full CNC control. Technological operations of machining can be programmed by simplefilling-in the pre-defined cycles or eventually by standard programming. Machines are therefore suitable forpiece and small-series production of simple as well as complex shapes of the workpieces from metal andplastic. Geometric accuracy of the machines fulfi lls norms ISO 1708 and ISO 230-1.

CHARACTERISTIC FEATURES

- Ideal machine for a user switching from universal lathe to CNC controlled machine.

- Easy and comfortable control.

- Long lifetime with focus on keeping high machining accuracy.

- Spindle drive through belts – minimization of vibration level that could negatively influence turning.

- Automatic gear shifting during the working cycle.

- Bearings with lifetime grease fi lling – low operating costs.

- Annealed machine components for internal stress removal – high accuracy and stability throughout lifetime of the machine.

- Covers with reinforced zones – high level of operator´s safety.

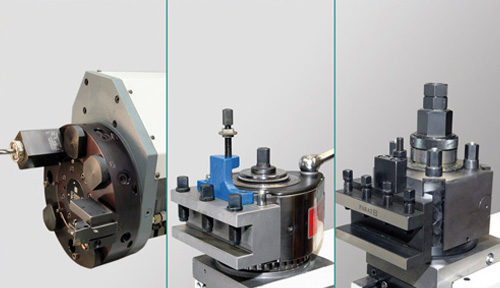

- Wide scope of executions and accessories – hydraulic clamping, hydraulic tailstock control, live tools, wide range of steadies and faceplates.

- Machining by built-in cycles (by filling-in parameters).

- Final grinding of guideways performed only after full bed assembly for maximum accuracy.

- Bed guideways hardened to 400HB min. depth 2mm.

- Positioning accuracy of every single machine is checked by laser measuring device.

- Heat-treated spindle with hardened surface.

- Bearings with lifetime grease – low operating costs.

KL285

KL435

SE520 SL

SR1, SR2, SR3, SR4, SR5

MANURHIN K’MX 1032

MANURHIN K’MX 916 CLEVER

MANURHIN K´MX816 CLEVER

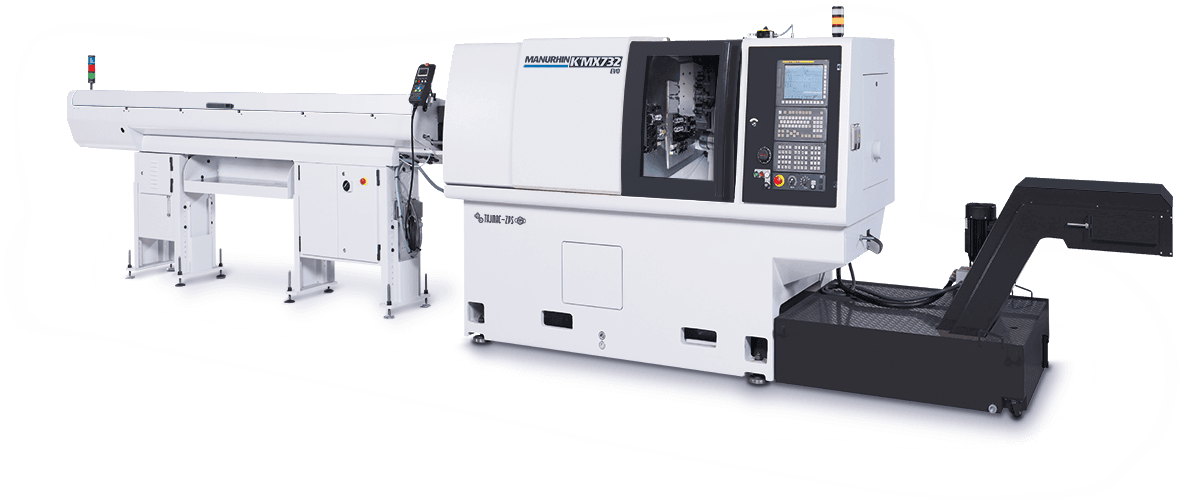

MANURHIN K´MX732EVO

MANURHIN K´MX632DUO

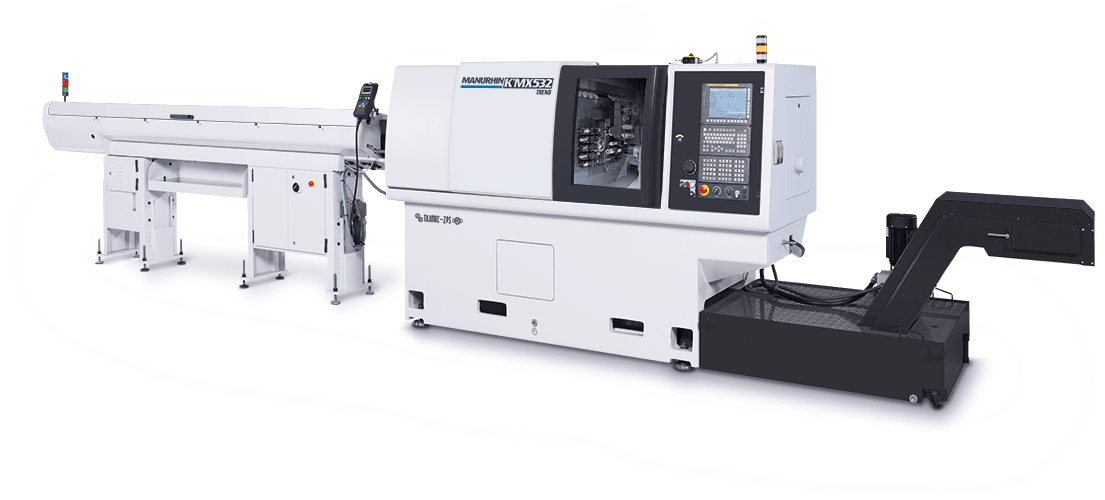

MANURHIN K´MX532 TREND

MANURHIN K´MX432

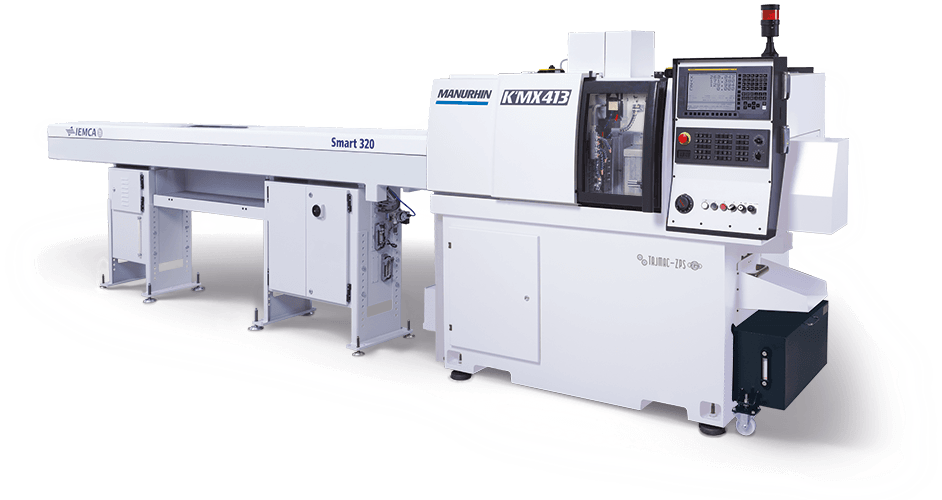

MANURHIN K´MX413

MORI-SAY TMZ867 CNC

MORI-SAY TMZ842 CNC

MORI-SAY TMZ642 CNC

MORI-SAY 832AC / 842AC

MORI-SAY 657AC, 667AC

MORI-SAY 632AC / 642AC

MORI-SAY 620AC

SPH 50 / D / DS

MASTURN

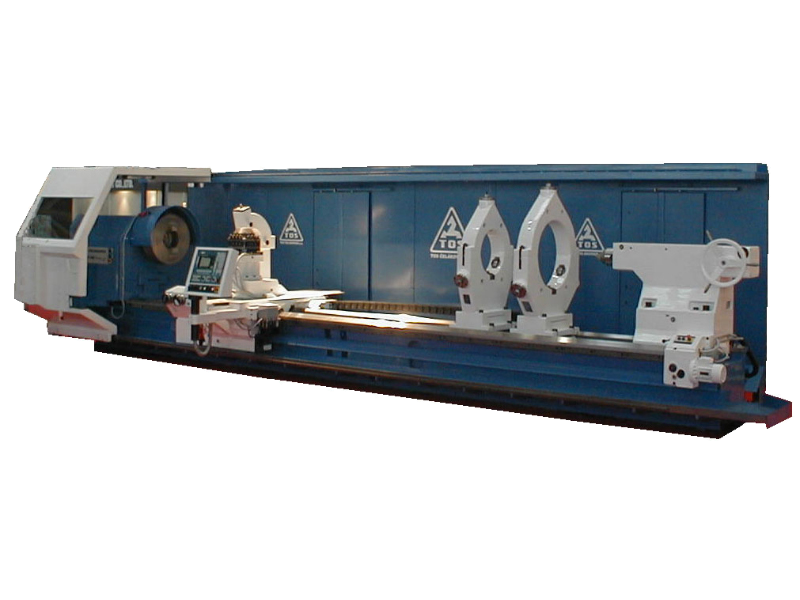

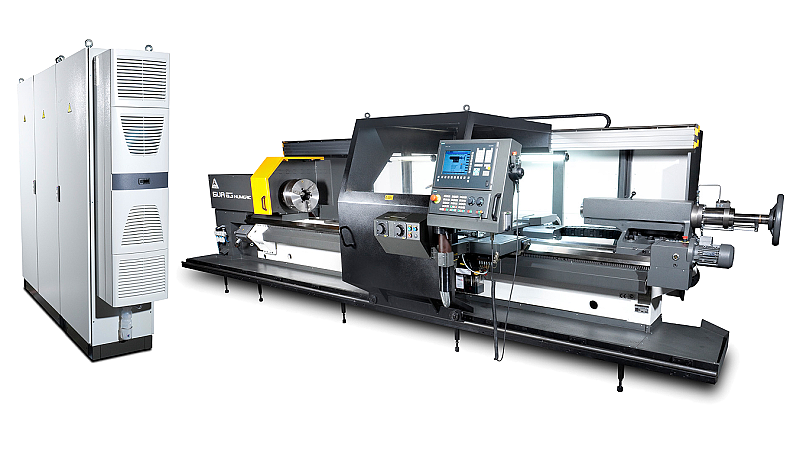

SUA 150 Numeric

SUA 125 Numeric

SUA 100 Numeric

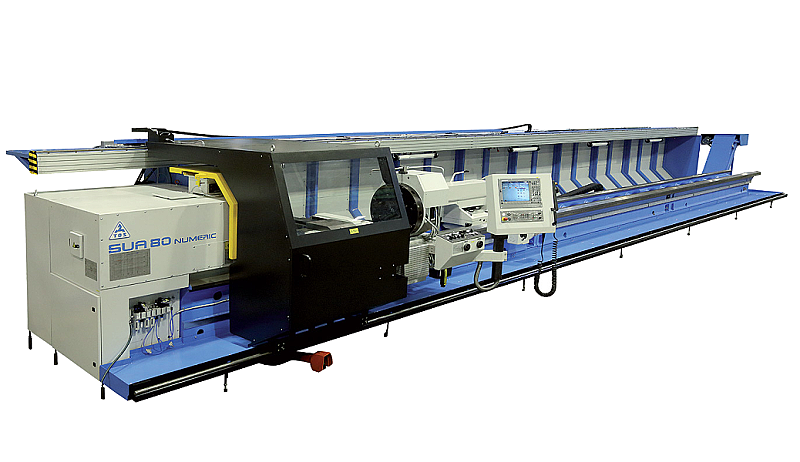

SUA 80 Numeric

SUA63 Numeric

SBX 500 CNC

SBE300 CNC

SBL 700 CNC

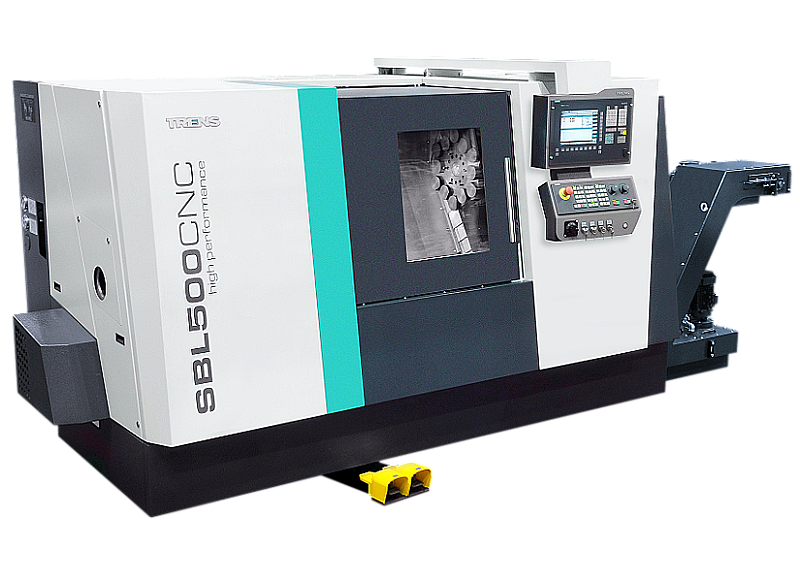

SBL 500 CNC

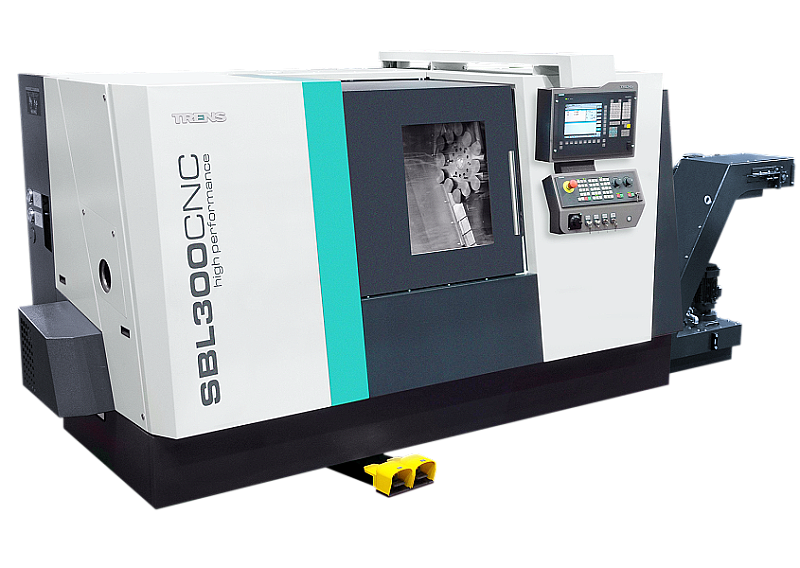

SBL 300 CNC

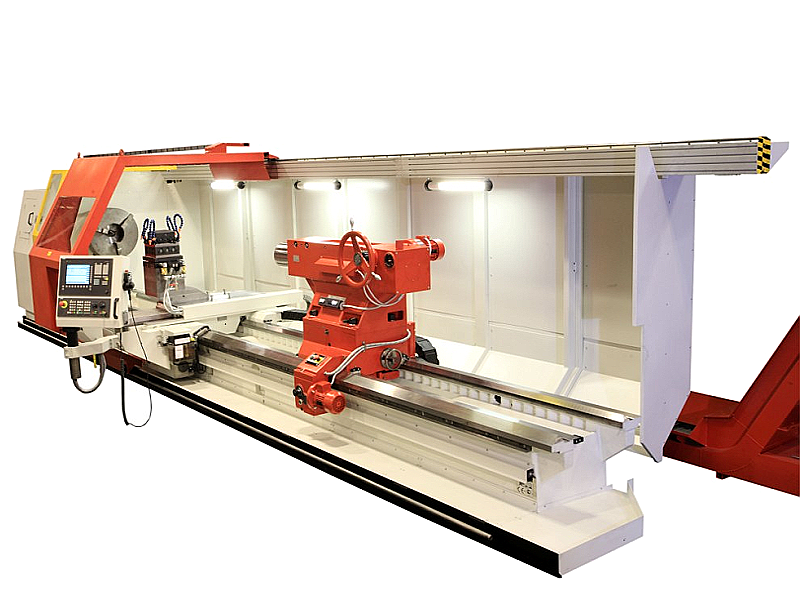

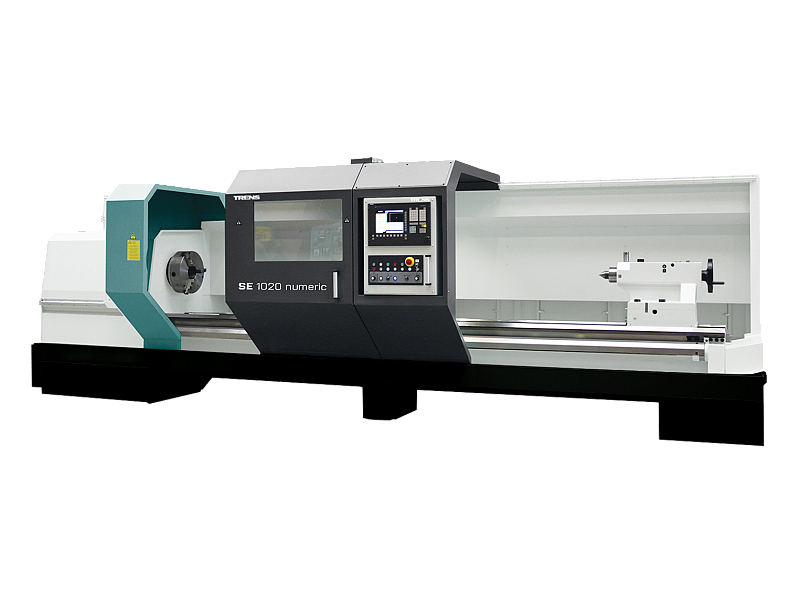

SE 1020 NUMERIC

SE 820 NUMERIC

SE 520 NUMERIC