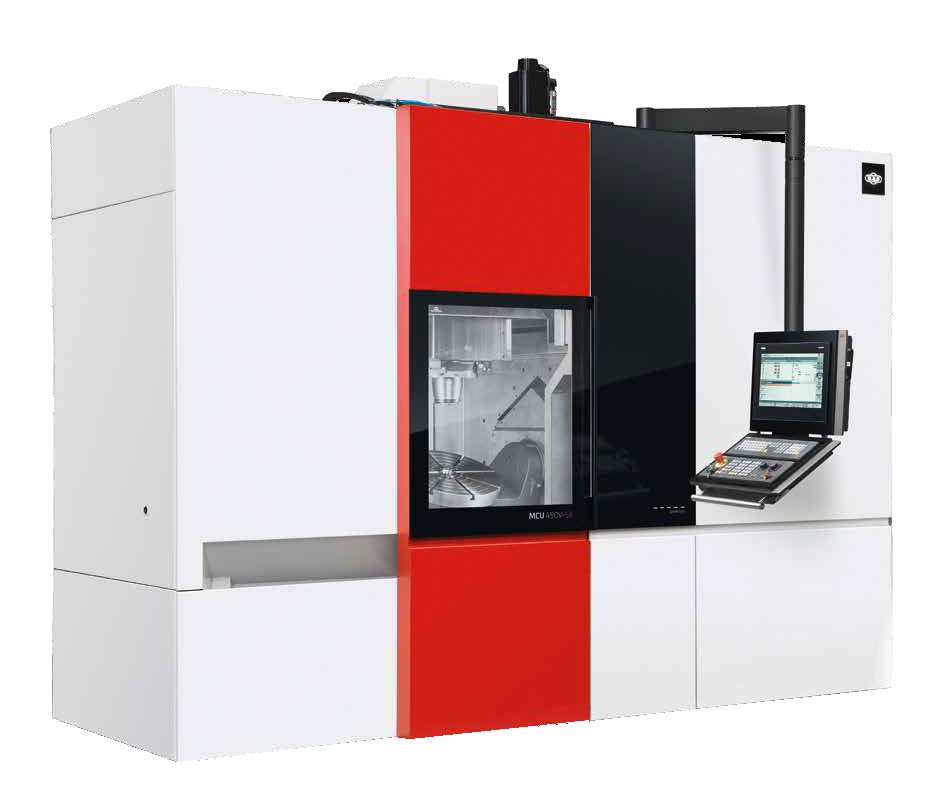

MCU 700V(T) – 5x

5-AXIS VERTICAL MACHINING CENTER MCU 700V(T)-5X

MCU 700 – vertical machining centre with wide technological utilisation like continuous five-axis milling, turning and other technologies (drilling, boring, reaming, thread cutting) with maximum productivity and accuracy. Automatic tool changer enables working in automatic cycle. Options using, the machine enables a using of productive tools with a cooling through spindle. Fitting for materials like – steel, cast iron, ferrous and non-ferrous metal, plastic, wood and graphite.

Characteristic machine design features

- moveable machine parts (slide, table and a spindle stock) are mounted on a roller linear guide ways

- powerful spindle KESSLER

- digital AC drives SIEMENS driving spindle and axes

- positioning by linear optical scales

- centric tool clamping

- control system SINUMERIK 840D sl

- rotary and tilting table with torque drives KESSLER / Peiseler

Machine working ambient

The vertical machining centre is designed to work in a normal workshop ambient, without influence of aggressive fumes and dust particles. The temperature should be kept in a range from +5° to 40°C, average temperature must not exceed 35°C by max. air humidity of 70%. The machine accuracy is ensured at ambient temperature of +20°C ±2°C.

Standard accessories

- electric equipment 3 x 400V/50Hz

- CNC control system SINUMERIK 840D sl

- digital AC drives for spindle and axis X, Y, Z, A, C – SIEMENS

- direct measurement of linear and rotary axis

- hydraulic unit – axis table clamping

- cooling unit for outside cooling

- thermal compensation

- centric tool clamping

- automatic lubricating of movable parts

- hand wheel

- workspace rinsing

- Switch board air-conditioning

- ETHERNET Card

- tool kit for a maintenance

- accompanying documentation (note – manual from control system on CD)

- re-cooling of spindle

- automatic roof mooving

- chip conveyor

- tool changer 32 positions (64* positions)

- machine state signalling

Special Accessories:

- INTERNAL COOLANT SUPPLY 6 MPA

- CENTRAL COOLING PRESSURE SELECTION

- FILTER CLOTH FOR FS 100

- SWITCHABLE COOLANT-AIR COOLING

- OIL MIST COLLECTOR FX

- SPIN WINDOW VISIPORT 220.C

- FILTRATION STATION FS100

- LIFTING EQUIPMENT MCU630

- LIFTING LOOP TAWGK 10 M24x63

Warning: Invalid argument supplied for foreach() in /data/1/8/1843503e-8530-4c63-aea5-fd8894436569/strojimport.com/web/wp-content/themes/strojimport/single.php on line 98

MC1040V

MCG 1000

MCG 820

MCG 810

MCH 1000 FIVE AXIS

MCH 1000

MCH 800 Five Axis

MCH 800

MCH 630

MCV 1000 5 AX

MCU 1100V(T) – 5X

MCU 700V(T) – 5x

MCU 450V(T) – 5x

MCV 1016 Quick

MCV 1270 Rapid / Sprint / Speed / Power

MCV 800 Quick

MCV 754 Quick

MCV1000 Rapid / Sprint / Speed / Power

MCV 750

MCG 3022

MCG 2318

MCV 2080

MCV 1680

MCV 1260