Request

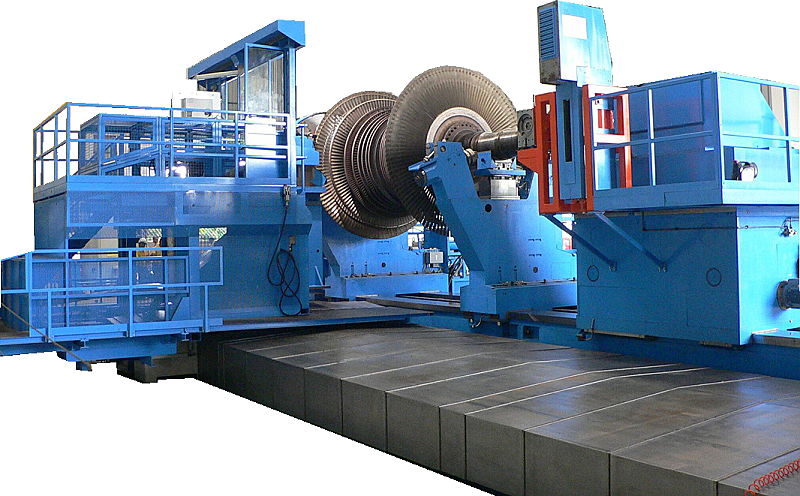

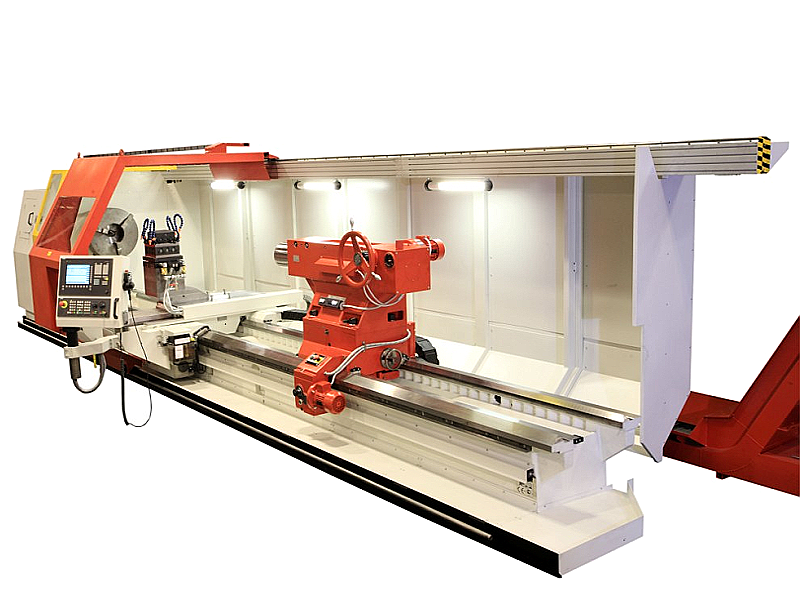

SBL 700 CNC

SBL 700 - Top representative of SBL range turning centers is designed for medium to large series production for demanding machining of large-dimensions workpieces of complex geometrical shapes. It is suitable for technological workshops focusing on large dimensions flange and shaft production in engineering where precision, quality and high production efficiency plays crucial role.

Turning center SBL 700 CNC

Top representative of SBL range turning centers is designed for medium to large series production for demanding machining of large-dimensions workpieces of complex geometrical shapes. It is suitable for technological workshops focusing on large dimensions flange and shaft production in engineering where precision, quality and high production efficiency plays crucial role.

General characteristics:

- The machine is designed for tooling shaft and flange parts up to diameter of 700mm.

- The machine can turn outer as well as inner cylindrical, conical and spherical surfaces, cut and repair threads and bore central holes with undriven tools. When the machine is equipped with driven tools, it can also carry out boring, off-axis boring and milling. Implementation with C axis with drive ebales atypical technological operations Machine implementation with bigger distance between centres allows production of long and slender shafts with the help of rests.

- The machine can employ advanced and powerful tools.

- The machine is suitable for small-lot or middle-lott production, or repair operations in a working surroundings free of aggressive liquids and their vapours.

- Machine design allows to deliver it in various implementations with a wide range of accessories according to customer requirements.

- In its basic version the machine has regulation spindle drive and feed drives controlled from control system, whose display is built in compact control panel together with auxilliary control elements.

- Workpiece is clamped into a chuck which is controlled by hydraulics with a possibility of support by tailstock. Centre sleeve is thrown out by hydraulics too. Workpiece can be gripped by outer or inner surface.

- Control systems are of modern type and thanks to their simple manipulation together with graphical support, they enable creating complex shapes of workpieces by means of parametrizing built-in cycles. In order to create programs of parts in such a way, no knowledge of programming is necessary and they can be created out of a drawing directly.

- Program properties are given by control system. Individual supplements of control system extend its programming possibilities and service comfort.

Most important features:

- 12-positional turret VDI 50 with/without live tool drive

- Remote diagnostics and data management

- Spindle drive output 37 kW (S1)

- Wide scope of versions and accessories – hydraulic clamping devices with chuck or collet chuck, bar feeders, tool probes, automatic door opening, vapour exhaust system

- Machine covers with reinforced areas – high level of operator protection

Does this model not meet your needs? We also have smaller option. More information to be found in our catalogue. The manufacturer reserves the right to change the product parameters and design without prior notice.

KL285

KL435

SE520 SL

SR1, SR2, SR3, SR4, SR5

MANURHIN K’MX 1032

MANURHIN K’MX 916 CLEVER

MANURHIN K´MX816 CLEVER

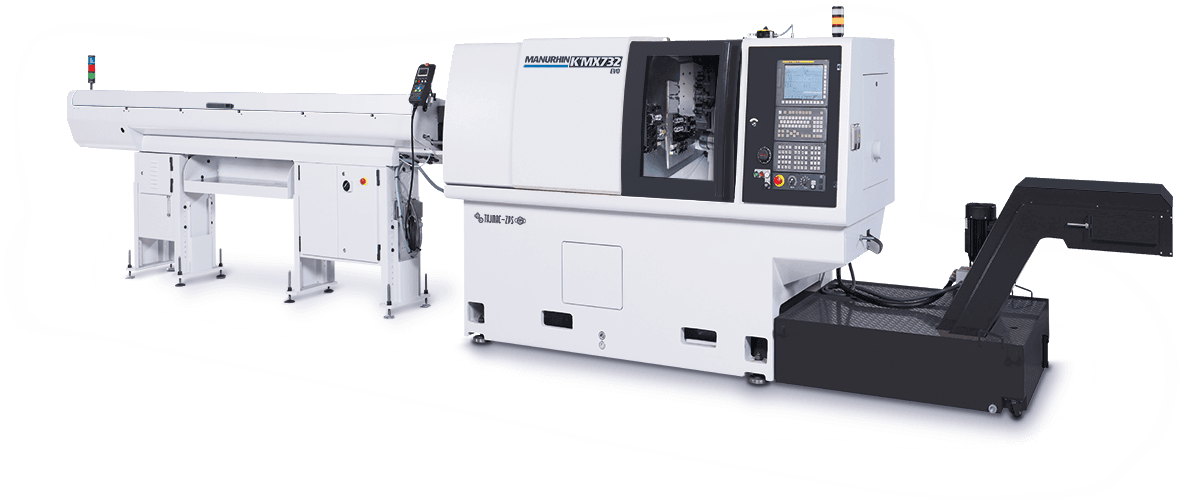

MANURHIN K´MX732EVO

MANURHIN K´MX632DUO

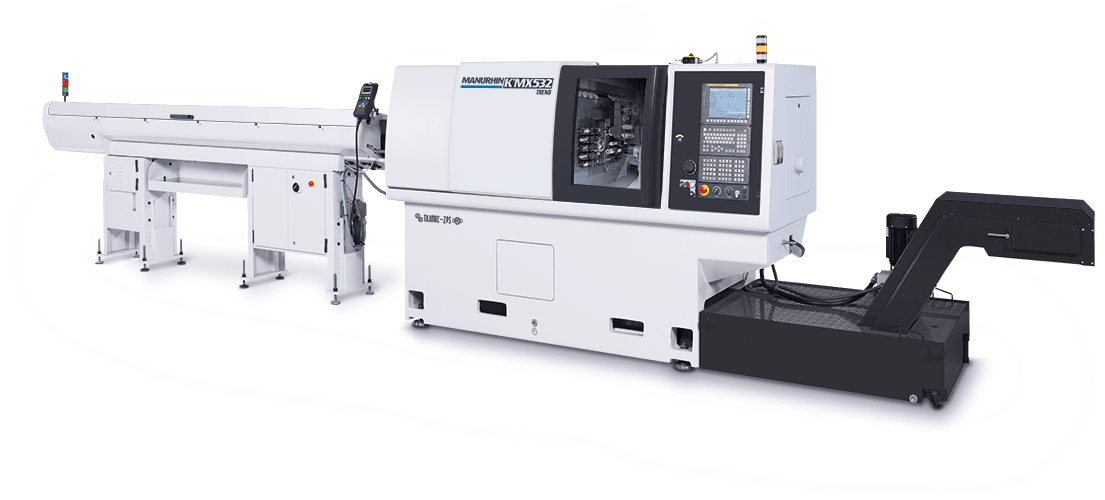

MANURHIN K´MX532 TREND

MANURHIN K´MX432

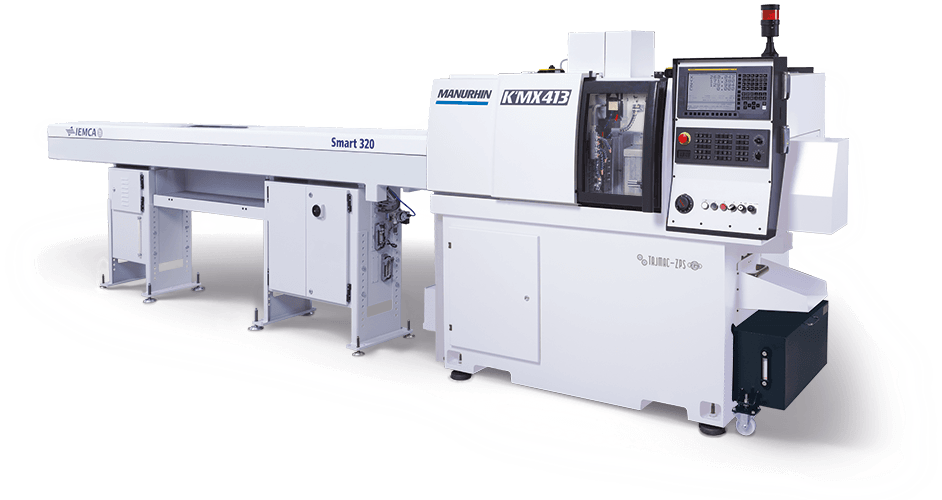

MANURHIN K´MX413

MORI-SAY TMZ867 CNC

MORI-SAY TMZ842 CNC

MORI-SAY TMZ642 CNC

MORI-SAY 832AC / 842AC

MORI-SAY 657AC, 667AC

MORI-SAY 632AC / 642AC

MORI-SAY 620AC

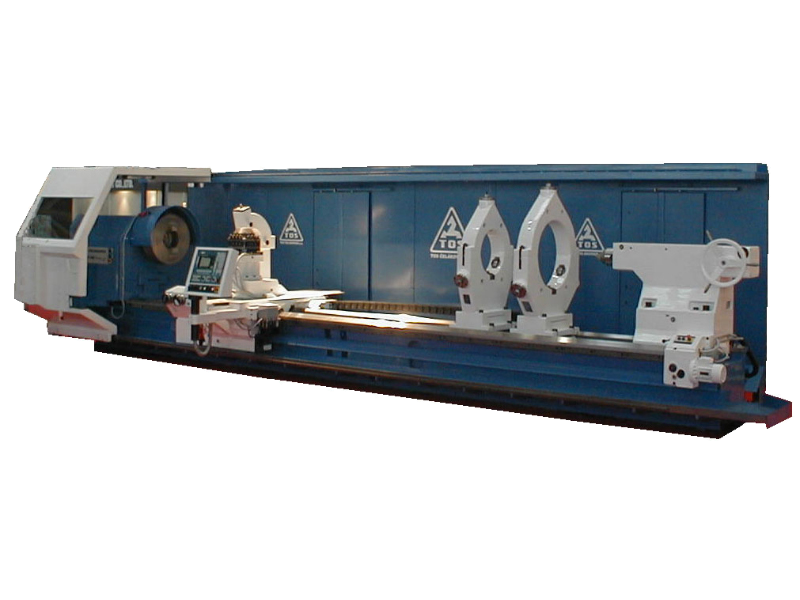

SPH 50 / D / DS

MASTURN

SUA 150 Numeric

SUA 125 Numeric

SUA 100 Numeric

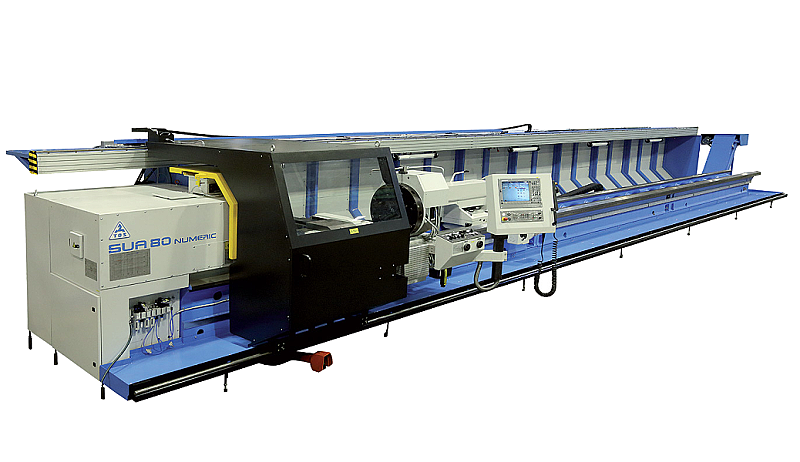

SUA 80 Numeric

SUA63 Numeric

SBX 500 CNC

SBE300 CNC

SBL 700 CNC

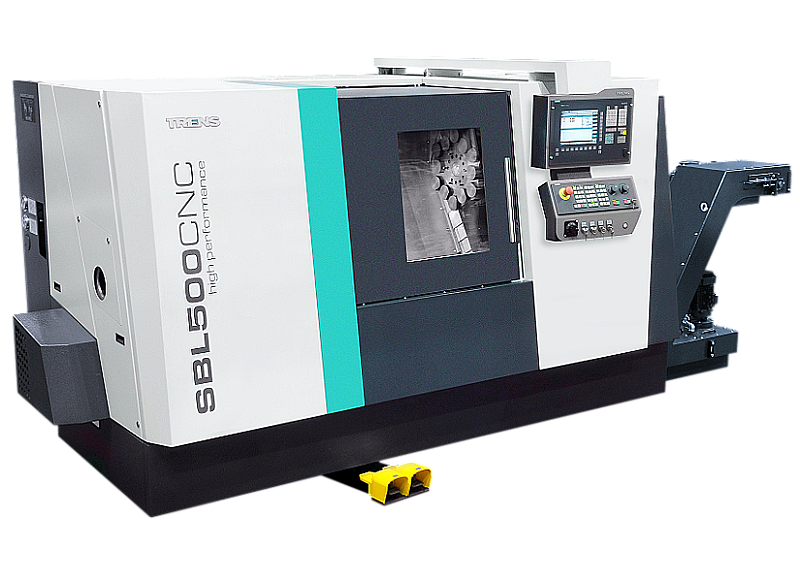

SBL 500 CNC

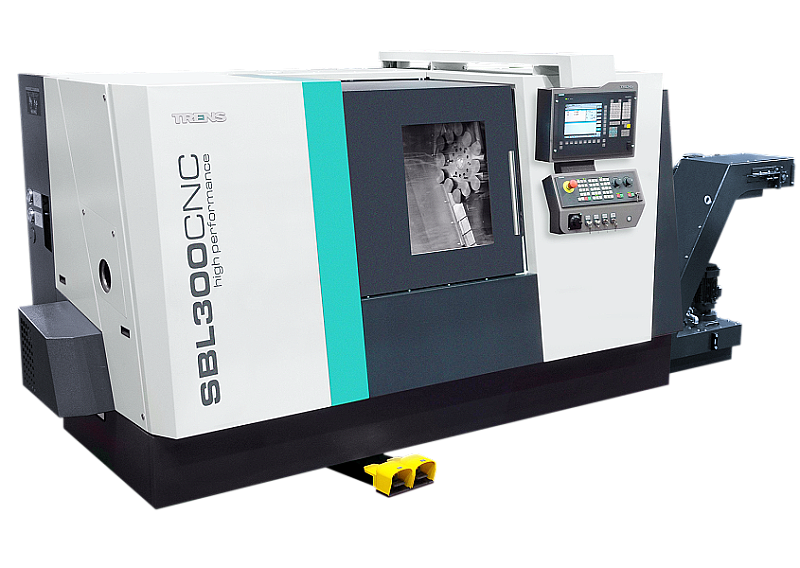

SBL 300 CNC

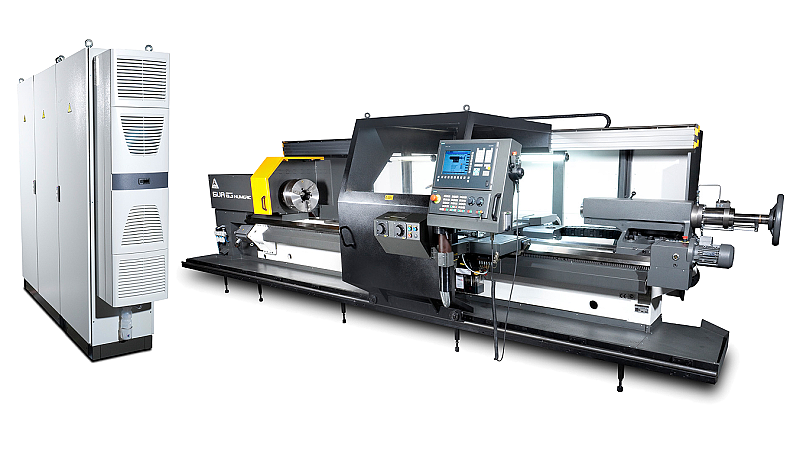

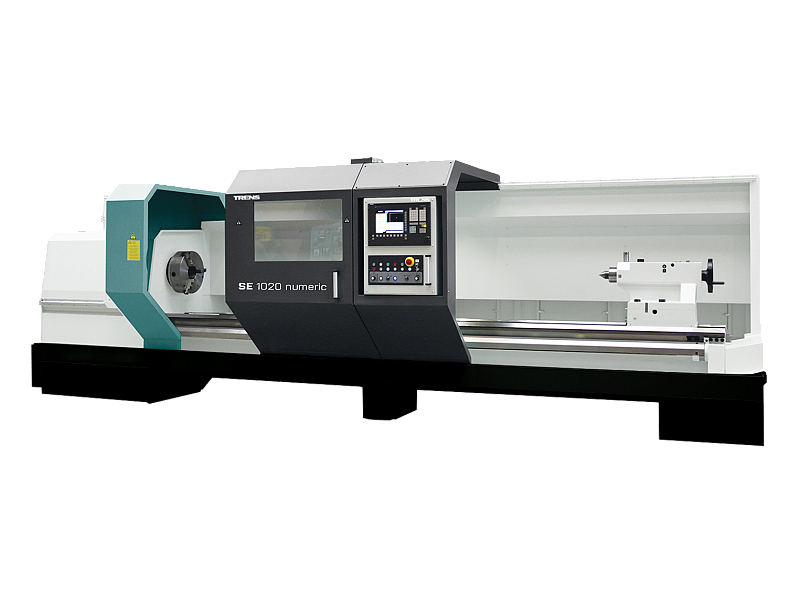

SE 1020 NUMERIC

SE 820 NUMERIC

SE 520 NUMERIC