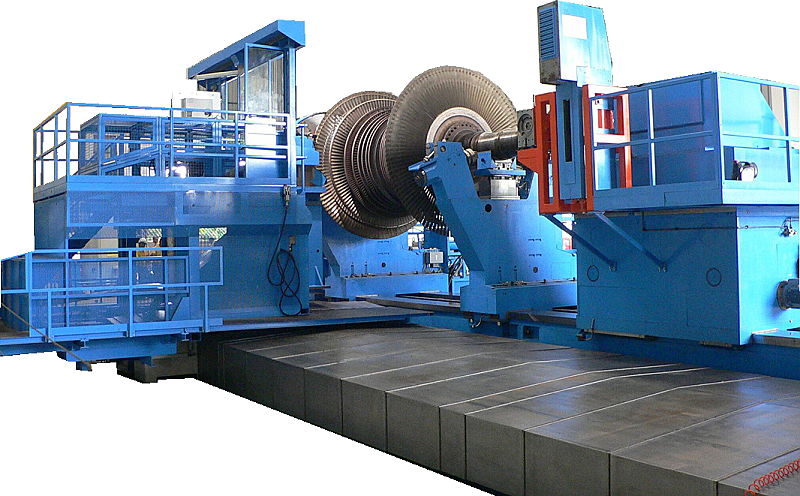

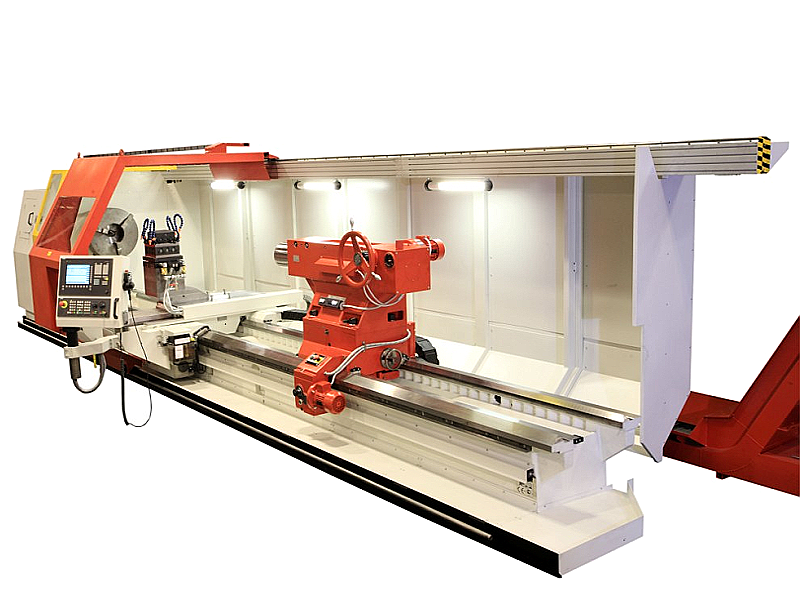

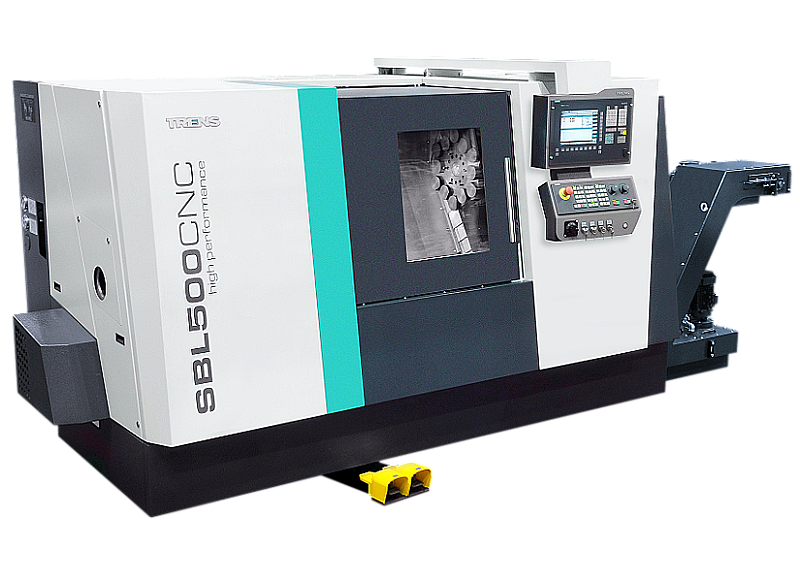

SBL 500 CNC

CNC turning center with rigid construction slant bed SBL 500

SBL 500 CNC – Turning center with rigid construction slant bed is designed not only for heavy roughing but for demanding finishing operations with focus on high accuracy and surface quality too. Exceptional steadiness of cutting process is ensured by high stiffness of individual machine components. Long-term operational reliability designates this machine for turning workshops with continuous operation and high productivity demands. Turning center can be operated in full automated mode when equipped with devices for automatic workpiece manipulation.

Most important features:

- 12-positional turret VDI 40 with/without live tool drive

- Remote diagnostics and data management

- Version with distance between centers of 1500 mm

- Direct spindle position measurement-high accuracy in out-of-axis machining at big diameters

- Wide scope of versions and accessories – hydraulic clamping devices with chuck or collet chuck, bar feeders, tool probes, automatic door opening, vapour exhaust system

- Machine covers with reinforced areas – high level of operator protection

Configuration of the basic execution:

- Control system SIEMENS 840D SINUMERIK Operate with TCU.

- Distance between centers d.b.c. 750.

- Axial turret without live tools.

- Spindle bore ø 92 mm with spindle nose DIN A2-8 (DIN55026 A & ISO702-I A2).

- Without spindle brake.

- Spindle speed 4200 min-1.

- Spindle power 22/30,8 kW (S1/S6-40%).

- Hydraulic 3-jaw chuck ø 250 mm with passaging hole ø 75 mm.

- C-axis (positioning of the spindle by main motor).

- Without tailstock.

- Chip pan.

- Electro cabinet ventilation – fans.

- Coolant pressure 6 bar.

- Tool probe – NO.

- Parts catcher – NO.

- Manual door opening.

- Follow rest – NO.

- Y-axis – NO.

- Z-axis measurement – Indirect measuring by motor encoder.

- Preparation for bar feeder – NO.

- Colour scheme – Standard paint – RAL 7035 / 7016 / 6153.

Optinal executions:

-

Control system:

- Control system SIEMENS 840D Sinumerik Operate with TCU; in standard available in languages: ENG,DEU,ITA,ESP,FRA,CHS; for other languages see optional accessories

- Control system FANUC 0iTD ManualGuide i; in standard available in languages: ENG,CSY,RUS;for other languages see optional accessories

Does this model not meet your needs? We also have smaller or bigger option. More information to be found in our catalogue. The manufacturer reserves the right to change the product parameters and design without prior notice.

KL285

KL435

SE520 SL

SR1, SR2, SR3, SR4, SR5

MANURHIN K’MX 1032

MANURHIN K’MX 916 CLEVER

MANURHIN K´MX816 CLEVER

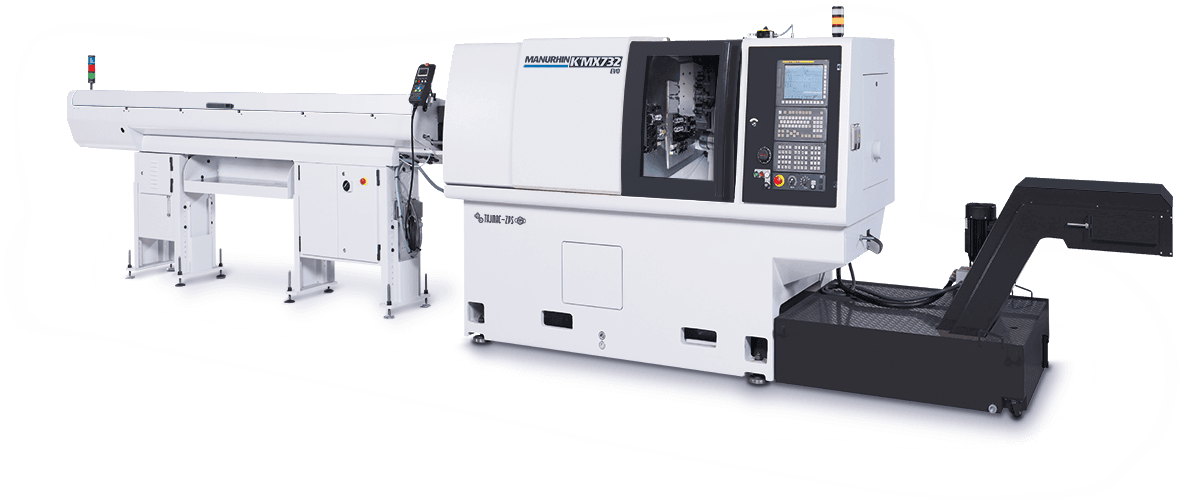

MANURHIN K´MX732EVO

MANURHIN K´MX632DUO

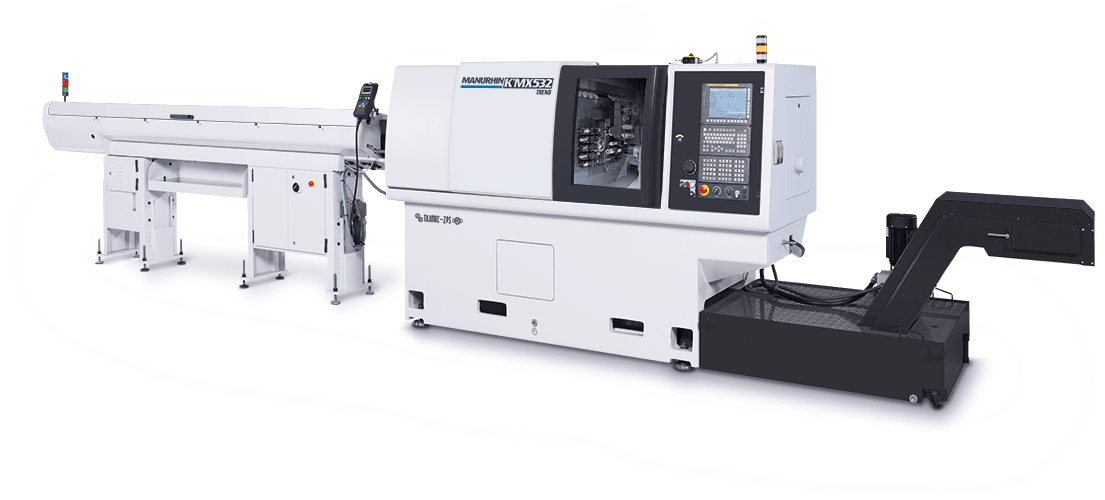

MANURHIN K´MX532 TREND

MANURHIN K´MX432

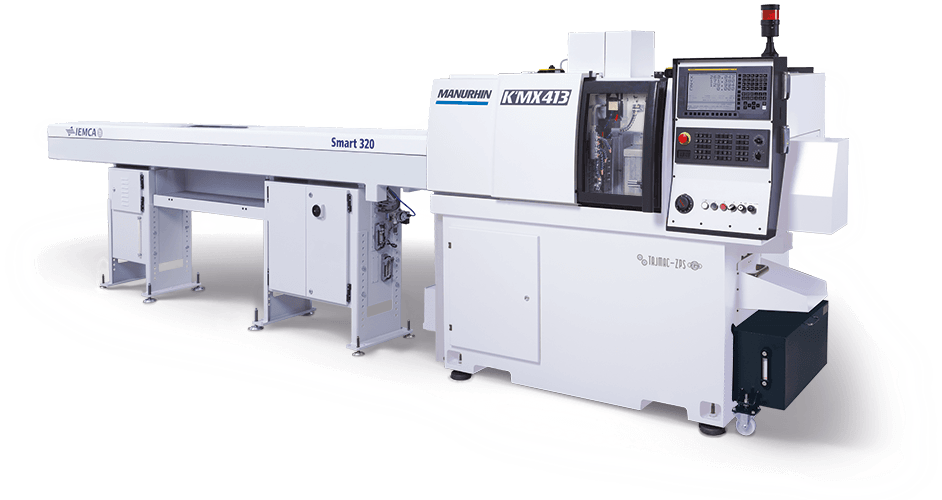

MANURHIN K´MX413

MORI-SAY TMZ867 CNC

MORI-SAY TMZ842 CNC

MORI-SAY TMZ642 CNC

MORI-SAY 832AC / 842AC

MORI-SAY 657AC, 667AC

MORI-SAY 632AC / 642AC

MORI-SAY 620AC

SPH 50 / D / DS

MASTURN

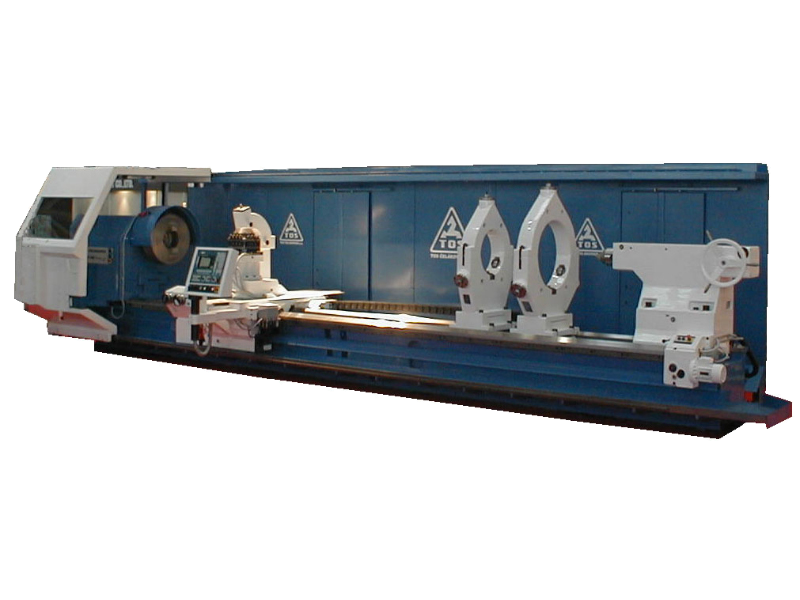

SUA 150 Numeric

SUA 125 Numeric

SUA 100 Numeric

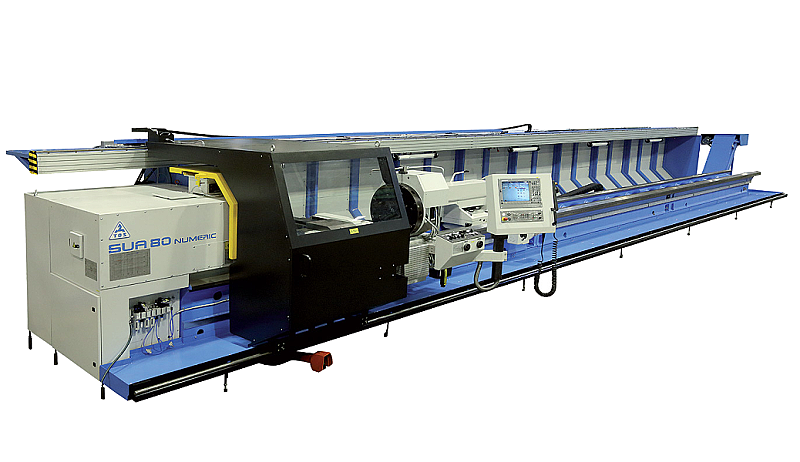

SUA 80 Numeric

SUA63 Numeric

SBX 500 CNC

SBE300 CNC

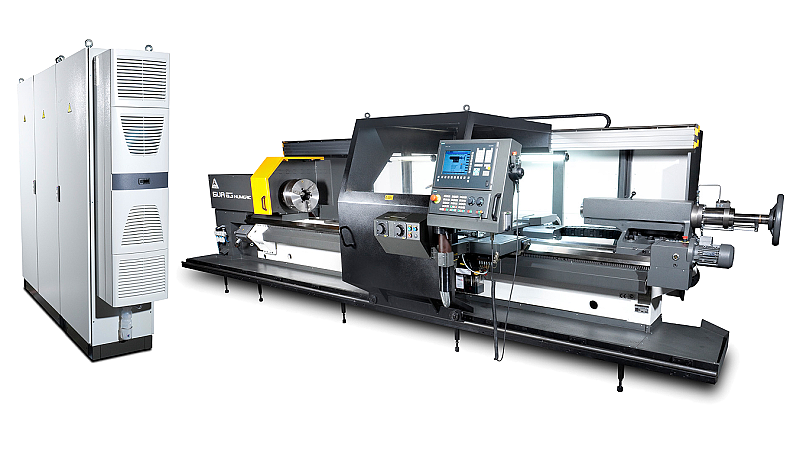

SBL 700 CNC

SBL 500 CNC

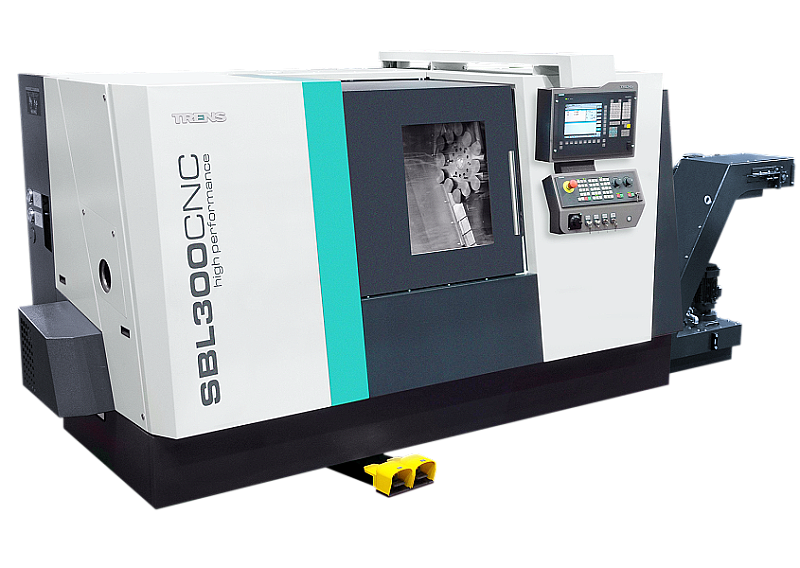

SBL 300 CNC

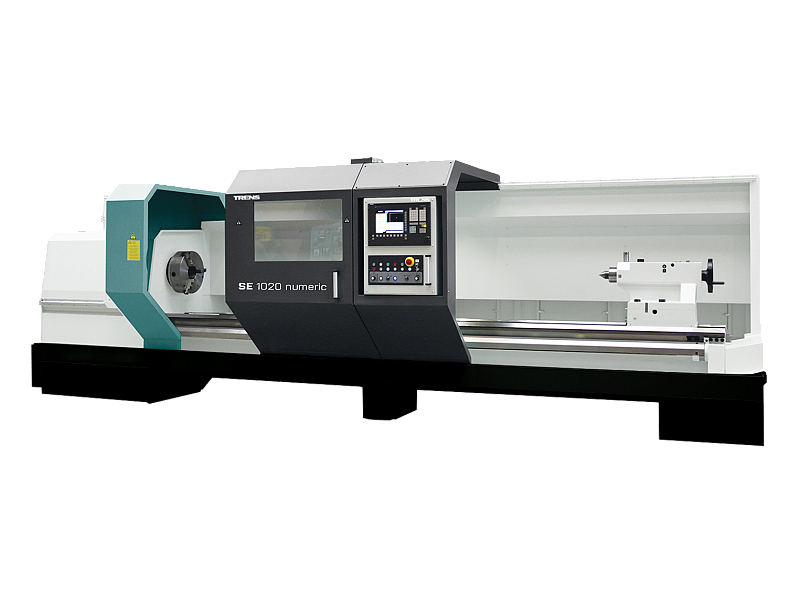

SE 1020 NUMERIC

SE 820 NUMERIC

SE 520 NUMERIC